Mazak Fusion Client

- Overview

- Applicable Machines

- Mazak Fusion Client Setup

- Troubleshooting

- Additional Resources

- Getting Help

Overview

Mazak Mazatrol Smooth control panel. Mazak machines with Windows-based controls (Fusion 640, Matrix, Nexus, Preview 3, Smooth) connect via the Fusion Client application using UDP port 51001.

MachineMetrics connects to Mazak CNC machines using the Mazak Fusion Client, a native connector that integrates directly with Mazak's application running on the Windows portion of the Mazak controller.

Key Features:

- Real-time machine data collection

- Direct communication with Mazak controls

- Automatic data item discovery

- Simplified setup process

- UDP communication on port 51001

Applicable Machines

The Mazak Fusion Client works with the following Mazak control types:

Supported Controls:

- Fusion 640 (may require a 16-bit PCMCIA Buffalo card and expansion slot if not present)

- Matrix

- Nexus

- Preview 3

- Smooth

🔴 Warning for Fusion 640: Fusion 640 controls typically run on Windows 98 or Windows 2000 operating systems. Finding compatible drivers for PCMCIA network cards can be very difficult or impossible with these legacy operating systems. Consider upgrading the control or be prepared for troubleshooting driver compatibility issues.

Note: The Preview G, Smooth G, and Smart controls require MTConnect instead of Fusion Client. Please contact Mazak to purchase MTConnect for these controls. See the MTConnect Connectivity Guide for setup instructions.

Mazak Fusion Client Setup

Prerequisites

Before beginning setup, ensure you have:

- Mazak Machine Requirements:

- Mazak Smooth control with Windows PC

- Network connectivity (Ethernet)

- Static or reserved DHCP IP address assigned

- Mazak Fusion Client application installed (or installation files)

- Network Requirements:

- Machine must be accessible from MachineMetrics Edge device

- Edge device must reach machine IP address

- UDP Port 51001 must be allowed through firewall

- Bi-directional communication required

- Access Requirements:

- Admin access to Windows PC on Mazak control

- Ability to install/configure Fusion Client

- MachineMetrics account with Manager or Executive permissions

Mazak control Windows desktop showing the system tray. The Fusion Client application icon (highlighted in red) should be visible in the taskbar when the service is running. Access the Windows side of the control to install and configure Fusion Client.

Installing Fusion Client

Step 1: Access MS Windows Menu

- On the Mazak control, access the Windows side of the machine

- Navigate to the Windows desktop

Step 2: Launch Fusion Client

- Go to

C:\CPCU\fmcnc - Double-click

Fusion Client.exe - Note: Nothing will appear to happen when you click the icon, but the application will now be running in the Windows system tray

Important: If your machine does not have the

C:\CPCUfolder in Windows Explorer, contact MachineMetrics Support and we can provide it.

Mazak control Windows desktop showing the system tray. The Fusion Client application icon (highlighted in red) should be visible in the taskbar when the service is running.

Step 3: Open Fusion Client Settings

- In the Windows system tray (bottom right), locate the Fusion Client icon

- Double-click the Fusion Client icon in the system tray

- The Fusion Client configuration window will open

CPC Cyber Monitor Satellite (IPC) application showing the Fusion Client configuration interface.

Step 4: Configure Connection Settings

- Click Change Settings

Communications Settings dialog where you'll configure the MachineMetrics Edge connection.

-

Click Add to add a new connection

-

Enter the following information:

- Network Name: Leave blank

- IP Address: Enter the static IP address of the MachineMetrics Edge device (e.g., 192.168.1.50)

- UDP Receive Port: Enter

51001 - Host Compatibility: Select Level 4 from the dropdown

-

Click OK or Apply to save the connection settings

Step 5: Configure Parameter Settings

- In the Fusion Client main menu, go to the Parameter tab

- Deselect the Close Button checkbox

- This prevents the Fusion Client from being accidentally closed

- Click OK or Apply

Step 6: Configure Firewall (If Enabled)

If the firewall is enabled on the Mazak CNC:

Option A: Disable Firewall (If Not Required)

- If you do not need the firewall enabled, disable it completely

Option B: Add Port Exception

- If the firewall must remain enabled, add a port exception for UDP port 51001

- Navigate to Windows Firewall settings

- Add inbound and outbound rules for UDP port 51001

Configuring the Connection

Step 1: Verify Network Connectivity

-

From MachineMetrics Edge device, ping the machine:

ping [MAZAK-IP-ADDRESS] -

Verify successful response

-

Test port connectivity if ping succeeds

Step 2: Note Required Information

Document the following:

- Machine IP Address: (e.g., 192.168.1.50)

- Fusion Client Port: UDP 51001 (standard for Mazak Fusion)

- Machine Name: For identification in MachineMetrics

- Machine Serial Number: (optional but recommended)

- Control Type: (Fusion 640, Matrix, Nexus, Preview 3, or Smooth)

Adding Machine in MachineMetrics

Step 1: Navigate to Machines

- Log into MachineMetrics at app.machinemetrics.com

- Click Assets → Machines

- Click Add Machine button

Step 2: Enter Machine Information

- Machine Name: Enter descriptive name (e.g., "Mazak-Integrex-01")

- Machine Type: Select appropriate type (Mill, Lathe, Multi-Axis, etc.)

- Machine Make: Mazak

- Machine Model: (e.g., Integrex, Quick Turn, Vertical Center)

- Serial Number: Enter if available

- Click Next or Continue

Step 3: Select Mazak Fusion as Connection Type

- In Data Collection Method dropdown, select Mazak Fusion Client

- Enter IP Address: [MAZAK-IP-ADDRESS]

- Enter Port: 51001 (standard UDP port for Mazak Fusion)

- Click Test Connection

- Verify "Connection Successful" message

- Click Save

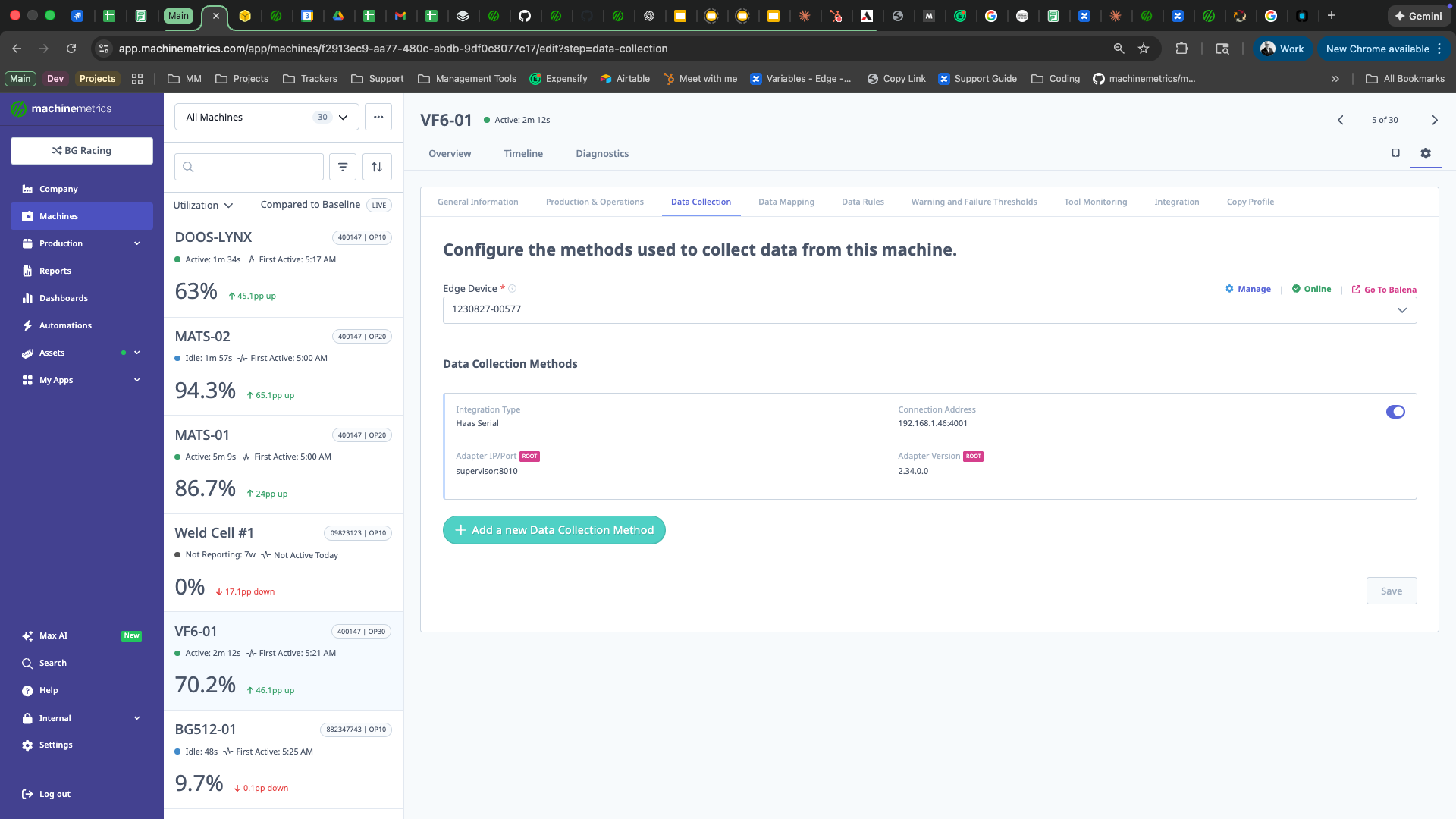

Data Collection tab showing configured adapter. For Mazak Fusion Client, you'll see the connection listed with the IP address and port. The adapter version and status are displayed, showing when the connection was last successful.

Step 4: Verify Data Collection

- After saving, machine should appear in machines list

- Status should show Reporting (green) within 1-2 minutes

- Click machine name to view machine page

- Navigate to Diagnostics tab

- Verify data items are populating

Part Counting Setup

Mazak machines offer multiple methods for part counting depending on your control type and requirements. This section covers how to configure part counting in MachineMetrics.

Understanding Mazak Part Counting

Mazak controls track part counts in two primary locations:

- COUNTER (MODAL) - Displayed on the main machine status screen

- PARTS COUNTER - Accessible via the work number menu system

Both counters can be used for MachineMetrics part counting depending on your preference and control configuration.

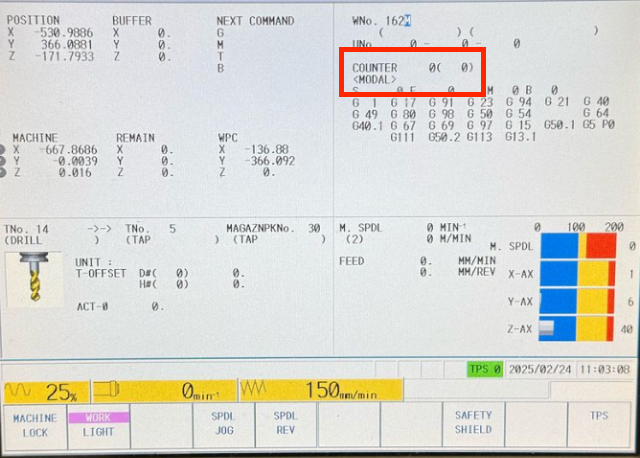

Mazak status screen showing the COUNTER (MODAL) value highlighted in red. This counter increments with each completed cycle and is commonly used for part counting.

Mazak status screen showing the COUNTER (MODAL) value highlighted in red. This counter increments with each completed cycle and is commonly used for part counting.

Mazak work number screen showing the PARTS COUNTER interface. The CONT. (continuous) and NUMBER columns track part counts. This menu is accessed via the work number system.

Mazak work number screen showing the PARTS COUNTER interface. The CONT. (continuous) and NUMBER columns track part counts. This menu is accessed via the work number system.

Part Counting Options

Mazak Fusion Client provides several part counting options:

Option 1: Default Part Counting (Recommended)

- Uses the machine's native counter

- Automatically increments based on cycle completion

- No additional configuration required

- Works with most Mazak controls

Option 2: Counter Modal

- Uses the COUNTER value displayed on the machine status screen

- Visible during machine operation

- Commonly used for production tracking

- Good for operators to verify counts

Option 3: Parts Counter (Work Number Menu)

- Uses the dedicated parts counter in the work number system

- May provide more detailed counting options

- Requires accessing specific menu on control

- Can track multiple part types

Configuring Part Counting in MachineMetrics

Step 1: Verify Part Count Data Item

- Go to machine Settings → Data Mapping tab

- Search for part count related data items:

PartCountorpart_countCounterorcounter_modalTotalPartsortotal_partsGoodPartsorgood_parts

- Verify the data item is mapped correctly

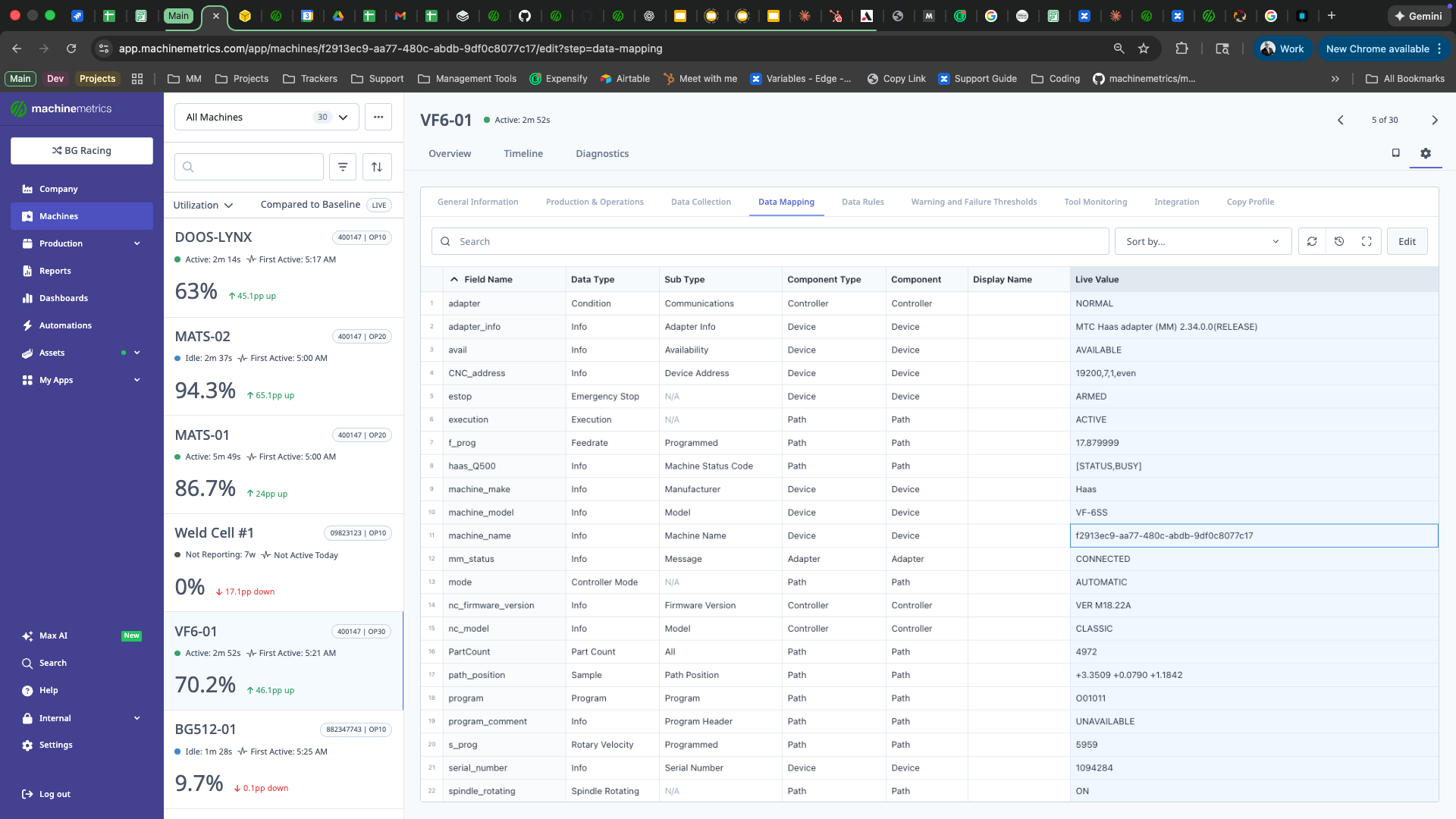

Data Mapping tab displays all data items collected from the Mazak machine. Search for part count-related data items and verify they are properly mapped with correct data types (EVENT or SAMPLE) and component types. The live values column shows current readings from the machine.

Step 2: Configure Part Count in Data Rules

- Navigate to Settings → Data Rules tab

- Under Part Count Metric, select the appropriate data item from dropdown:

- PartCount: Standard cumulative counter

- Counter: Modal counter from status screen

- GoodParts: Only counts good/accepted parts

- Configure reset behavior (optional):

- Reset on Program Change: Counter resets when new program loads

- Reset on Shift Change: Counter resets at shift boundaries

- Never Reset: Cumulative counter

- Click Save

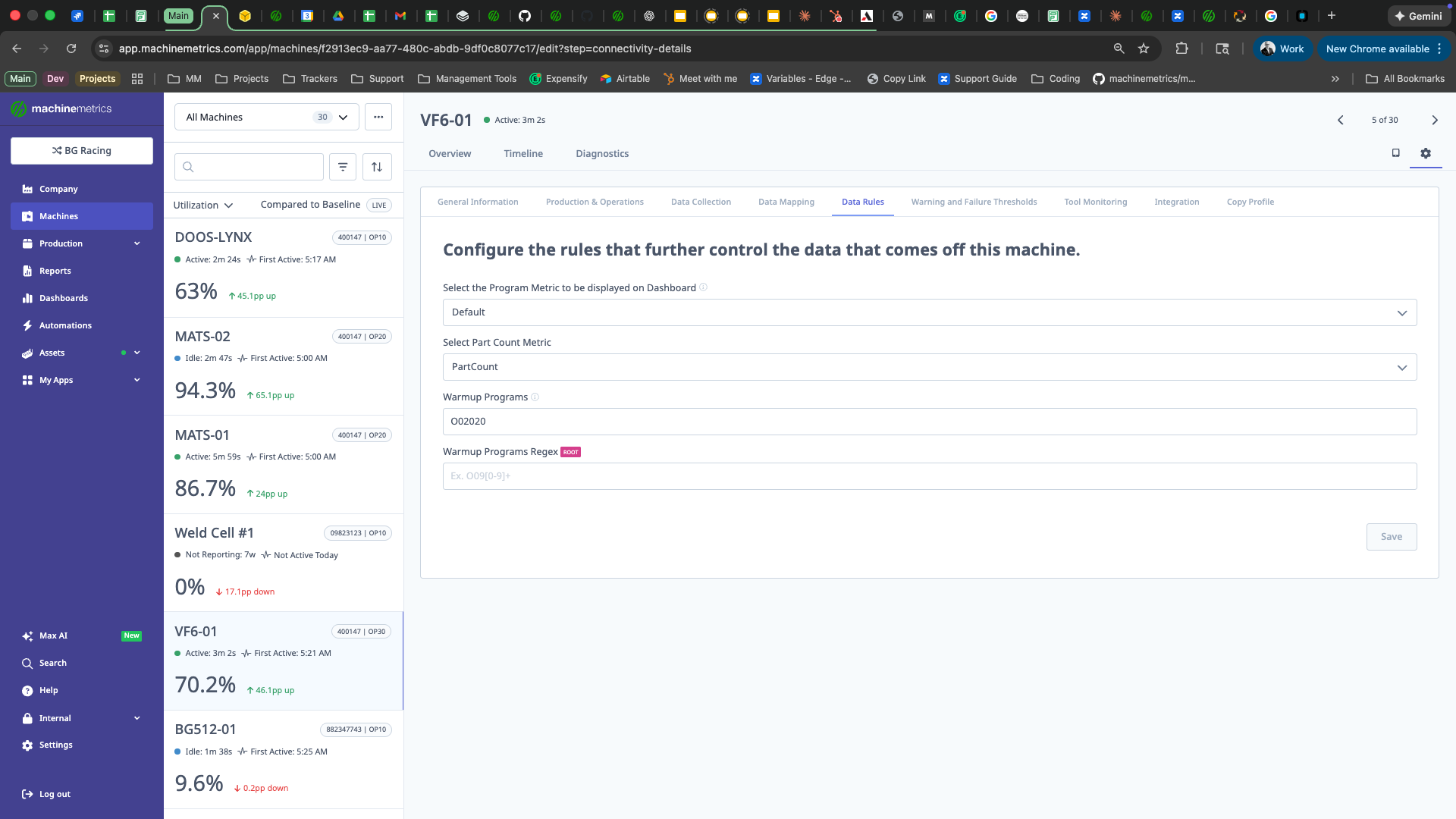

Data Rules tab where you configure which metrics are displayed on dashboards. Select the Part Count Metric from the dropdown to specify which data item should be used for part counting.

Step 3: Test Part Counting

- Run a test part on the machine

- Watch the counter on the Mazak control increment

- In MachineMetrics, navigate to machine page

- Click Parts tab

- Verify part count increments after cycle completes

- Check Timeline view for real-time part count updates

- Verify part appears in production runs with correct timestamp

Step 4: Verify Part Counter Accuracy

Compare the counts:

- Note the counter value on the Mazak control (COUNTER or PARTS COUNTER)

- Check the part count in MachineMetrics

- Ensure values match

- If there's a discrepancy, check Data Mapping configuration

Troubleshooting Part Counting

Problem: Parts Not Counting

Possible causes:

- Part count data item not mapped correctly

- Counter not incrementing on machine

- Data Rules not configured

- Machine cycle not completing properly

Solutions:

- Verify counter increments on the Mazak control itself

- Check Data Mapping for part count data item

- Ensure Data Rules has Part Count Metric selected

- Review machine cycle completion (check for alarms/interruptions)

- Verify the Fusion Client is receiving counter data

Problem: Part Count Incorrect or Off by Several Parts

Possible causes:

- Counter reset on machine but not in MachineMetrics

- Multiple part counters being tracked

- Manual counter adjustments on control

Solutions:

- Reset part counter in MachineMetrics to match machine

- Verify you're using the correct counter (COUNTER vs PARTS COUNTER)

- Check if operator is manually adjusting counter on control

- Consider using "good parts" counter if available

Problem: Part Counter Resets Unexpectedly

Possible causes:

- Data Rules configured to reset on program change

- Machine counter reset by operator

- Shift change reset enabled

Solutions:

- Check Data Rules reset behavior settings

- Change reset behavior to "Never Reset" if cumulative count needed

- Train operators not to reset counter during production

- Use MachineMetrics counter rather than machine counter for reporting

Resetting Part Counter

On the Machine:

- Access the work number menu or counter display

- Find the counter reset function (varies by control)

- Reset the counter to zero or desired value

- MachineMetrics will sync within 1-2 minutes

In MachineMetrics:

- Navigate to machine Parts tab

- Click Reset Counter (if available)

- Or manually adjust in Data Rules if needed

- Changes take effect immediately

Best Practice:

- Reset counters at the start of each shift for shift-based tracking

- Or maintain cumulative counters for total production metrics

- Document reset procedures for operators

Troubleshooting

Mazak Fusion Client Issues

Problem: Connection Failed

Possible causes:

- Fusion Client not running on Mazak control

- Incorrect IP address or port

- Firewall blocking connection

- Network connectivity issue

Solutions:

- Verify Fusion Client is running on Mazak Windows PC

- Check Task Manager for Fusion Client process

- Restart Fusion Client service

- Ping machine IP from Edge device

- Verify UDP port 51001 is allowed through firewall (both directions)

- Check Windows Firewall on Mazak control

- Verify network switch/router allows UDP traffic

- Check Fusion Client logs for errors

Firewall Configuration:

- Protocol: UDP

- Port: 51001

- Direction: Bi-directional (both inbound and outbound)

- Source: MachineMetrics Edge device IP

- Destination: Mazak machine IP

Problem: Machine Shows "Not Reporting"

Possible causes:

- Network interruption

- Fusion Client crashed

- Machine control restarted

Solutions:

- Check network connectivity

- Restart Fusion Client application

- Restart machine control's Windows PC

- Verify IP address hasn't changed (use static IP)

- Check MachineMetrics Edge device connectivity

Problem: Missing Data Items

Possible causes:

- Fusion Client not configured to share all data

- Data items not available on this control

- Incorrect data mapping

Solutions:

- Check Fusion Client configuration for data item visibility

- Review Mazak control capabilities

- Verify data mapping in MachineMetrics settings

- Contact MachineMetrics support for data item availability

Additional Resources

MachineMetrics Resources:

- Machine Settings Guide - Configure machine settings

- Connectivity Overview - Compare connectivity methods

- MTConnect Guide - Alternative MTConnect setup

- Transform Adapter Scripts - Advanced data transformation

Mazak Resources:

- Mazak Fusion Client documentation (contact Mazak)

- Mazak control programming manual

- Mazak system variables reference

- Mazak networking and communication manual

Networking Resources:

- Network Requirements - Firewall and port configuration

- Edge Device Setup - Configure MachineMetrics Edge

Getting Help

MachineMetrics Support:

- Email: support@machinemetrics.com

- Phone: 844-822-0664

- Support Portal: https://support.machinemetrics.com

Before Contacting Support:

- Note the Mazak control type and model

- Document any error messages

- Capture screenshots of configuration screens

- Check machine and Edge device connectivity

- Review adapter logs if available

Information to Provide:

- Machine make, model, and control type

- Connection method (Fusion Client)

- IP address and port configuration

- Description of issue and when it started

- Any recent changes to machine or network

- Screenshots of error messages or configurations