IFM IO-Link Connectivity

- Overview

- What is IO-Link

- Supported Devices

- Prerequisites

- Device Setup

- MachineMetrics Configuration

- Connecting Sensors

- Data Mapping

- Troubleshooting

- Additional Resources

- Getting Help

Overview

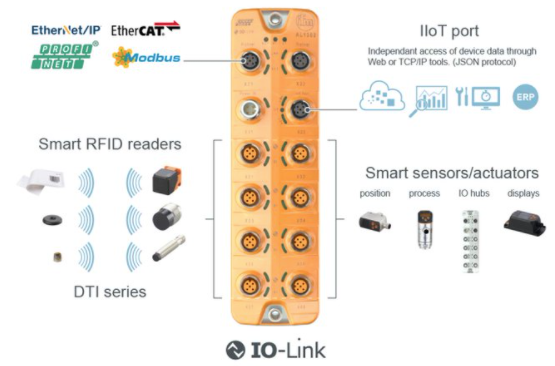

IFM IO-Link master block and sensors. MachineMetrics partners with IFM to connect IO-Link conforming sensors for temperature, pressure, flow, vibration, and other process data collection.

MachineMetrics partners with IFM to provide seamless connectivity to a wide range of IO-Link sensors for industrial data collection. This integration allows you to connect temperature sensors, pressure sensors, flow meters, vibration sensors, and many other smart sensors to capture real-time process data from your production environment.

Key Features:

- Connect any IO-Link conforming sensor to MachineMetrics

- Automatic sensor discovery and configuration

- Support for IFM IO-Link master blocks with IoT ports

- Real-time data collection from multiple sensors

- Cross-manufacturer sensor compatibility (IO-Link standard)

Partnership with IFM:

MachineMetrics has a strategic partnership with IFM to enable connectivity to their extensive portfolio of industrial sensors. All IFM IO-Link sensors are supported through this integration.

What is IO-Link

IO-Link is an open industrial communication protocol standard (IEC 61131-9) that enables intelligent sensors and actuators to communicate with control systems and gateways.

Key Characteristics:

- Device Protocol: Standardizes data exchange between sensors and gateway devices (master blocks)

- Vendor Neutral: Sensors from different manufacturers are cross-compatible with any IO-Link master block

- Point-to-Point Communication: Each sensor connects to a port on the master block

- Bidirectional: Supports both data collection and sensor configuration

What IO-Link is NOT:

- ❌ NOT a data contextualization standard (like MTConnect)

- ❌ NOT a standardized communication protocol between master block and external applications

- ❌ Because of this, MachineMetrics support is limited to specific master blocks

How It Works:

- Sensors connect to individual ports on the IO-Link master block

- Master block communicates with sensors using IO-Link protocol

- Master block exposes sensor data via its own protocol (IoT, EtherNet/IP, Modbus, etc.)

- MachineMetrics Edge connects to the master block to collect sensor data

Supported Devices

Master Blocks

MachineMetrics currently supports:

✅ IFM Master Blocks with IoT Data Port

- IFM AL1350 (IO-Link master, 8 ports, IoT interface)

- IFM AL1352 (IO-Link master, 4 ports, IoT interface)

- Other IFM blocks with dedicated IoT ethernet port

Important Notes:

- ⚠️ Not all IFM blocks have an IoT port - Verify your master block model

- ❌ EtherNet/IP-based blocks cannot be supported via our EtherNet/IP integration

- ⚠️ Modbus-based blocks can be supported as a Modbus integration, but data must be unpacked manually (not recommended) - See Modbus TCP Guide

- 📝 Additional master block models may be supported in the future

Sensors

✅ All IO-Link Conforming Sensors

The integration supports any sensor that conforms to the IO-Link standard, including but not limited to:

IFM Sensors (Extensive Portfolio):

- Temperature sensors

- Pressure sensors

- Flow meters

- Level sensors

- Vibration monitoring sensors

- Position sensors

- Distance sensors

- Humidity sensors

- Photoelectric sensors

- Inductive proximity sensors

Other Manufacturers:

- Balluff sensors

- Sick sensors

- ifm electronic sensors

- Turck sensors

- Any IO-Link compliant sensor

Prerequisites

Before setting up IO-Link connectivity, ensure you have:

Hardware Requirements:

- IFM IO-Link master block with IoT port

- IO-Link sensors (IFM or other manufacturers)

- Network cable (Cat5e or Cat6) for master block

- MachineMetrics Edge device on the same network

- Appropriate M12 cables for sensor connections

Network Requirements:

- Available static IP address on your network

- Network switch or router with available port

- Ethernet access between Edge device and master block

Software Requirements:

- IFM's configuration software (for initial setup)

- Download from: https://www.ifm.com/us/en/category/095_010_010

- MachineMetrics account with IO-Link integration enabled

Access Requirements:

- Physical access to install master block and sensors

- Network configuration permissions

- Knowledge of sensor mounting locations

Device Setup

IFM Master Block Configuration

Step 1: Physical Installation

- Mount the IFM master block on DIN rail or suitable location

- Connect power supply to master block (24V DC typical)

- Verify power LED illuminates

Step 2: Identify IoT Port

IFM master blocks support multiple protocols on different physical ports:

- IoT Port - Required for MachineMetrics integration (Ethernet with RJ45)

- EtherNet/IP Port - NOT compatible with this integration

- Modbus Port - NOT recommended (requires manual configuration) - See Modbus TCP Guide if needed

Critical: Ensure you connect the IoT port (not EtherNet/IP or Modbus port) to your network.

Step 3: Connect to Network

- Connect network cable from the IoT port to your network switch

- Verify link lights on Ethernet port are active

Network Configuration

Step 1: Install IFM Configuration Software

- Download IFM's configuration software from: https://www.ifm.com/us/en/category/095_010_010

- Install on a PC connected to the same network

- Launch the configuration tool

Step 2: Discover Master Block

- Open IFM configuration software

- Click Scan or Discover Devices

- Locate your master block in the list (note MAC address if multiple devices)

Step 3: Assign Static IP Address

- Select your master block in the configuration software

- Navigate to Network Settings or IoT Port Configuration

- Set IP Configuration to Static (Manual)

- Enter network information:

- IP Address: (e.g., 192.168.1.150)

- Subnet Mask: (e.g., 255.255.255.0)

- Gateway: (e.g., 192.168.1.1)

- Click Apply or Write Configuration

- Document the IP address for MachineMetrics configuration

Step 4: Verify Configuration

- Disconnect configuration PC

- Reconnect to network

- Verify master block is accessible at the assigned IP address

- Test with ping:

ping 192.168.1.150

Sensor Port Configuration

Step 1: Set Port Operating Modes

IFM master blocks allow individual port configuration:

- In IFM configuration software, navigate to Port Configuration

- For each port you'll use, set mode to IO-Link

- Other modes (Digital Input, Digital Output) will not work with this integration

Step 2: Connect Sensors

- Connect IO-Link sensors to master block ports using M12 cables

- Ports are numbered (typically Port 1 - Port 8 or Port 1 - Port 4)

- Document which sensor is connected to which port

Step 3: Verify Sensor Detection

- In IFM configuration software, view Port Status

- Verify each connected sensor shows:

- Status: Connected or Active

- Vendor ID: Numeric identifier for manufacturer

- Device ID: Numeric identifier for sensor model

- Note the Vendor ID and Device ID for each sensor (useful for troubleshooting)

MachineMetrics Configuration

Automatic Configuration

In most cases, the IO-Link integration will automatically configure itself based on IODD (IO Device Description) files.

Step 1: Add Machine in MachineMetrics

- Log into MachineMetrics at app.machinemetrics.com

- Navigate to Assets → Machines

- Click Add Machine

- Enter machine/sensor details:

- Name: (e.g., "Hydraulic-Press-Sensors" or "Assembly-Station-01")

- Type: (Select appropriate type or "Sensor Station")

- Click Next

Step 2: Select IO-Link Integration

- In Data Collection Method, select IO-Link or IFM IoT

- If not visible, contact MachineMetrics support

Step 3: Enter Master Block IP Address

- Enter the IFM master block's IP address (e.g., 192.168.1.150)

- The connector will automatically discover connected sensors

Step 4: Save and Test

- Click Test Connection

- MachineMetrics will:

- Connect to the master block

- Discover connected sensors

- Automatically create data items for each sensor

- If successful, click Save

Note: The IO-Link connector automatically discovers and configures sensors. No manual adapter script configuration is required.

Data Item Naming Convention

Automatically-configured sensors produce data items with a specific naming structure:

Format:

iolink_p<n>_<vendorid>_<deviceid>_<subindex>_<shortname>

Components:

<n>- Port number (1-8 or 1-4, depending on master block)<vendorid>- Manufacturer's vendor ID<deviceid>- Specific device/model ID<subindex>- Data item index within sensor's process data (starts at 1)<shortname>- Truncated, processed display name for identification

Example: IFM Humidity Air Sensor

IFM humidity/temperature sensor (Vendor ID: 310, Device ID: 1337) connected to Port 2:

iolink_p2_310_1337_1_humidity

iolink_p2_310_1337_2_temperature

iolink_p2_310_1337_3_devicestatus

Explanation:

p2- Connected to Port 2310- IFM vendor ID1337- Humidity sensor device ID1,2,3- Sub-indexes for different measurementshumidity,temperature,devicestatus- Shortened names

Data Transformation

The IO-Link connector uses automatic sensor discovery and configuration. Manual configuration of process data, bit offsets, gradients, and offsets is not required.

If you need to transform or manipulate the IFM data items to solve your specific use case, use transform adapter scripts to process the automatically discovered data items.

See the Transform Adapter Scripts Guide for information on:

- Renaming data items

- Applying mathematical transformations

- Combining multiple data items

- Creating custom variables from sensor data

Connecting Sensors

Step 1: Plan Sensor Placement

- Identify measurement points on your equipment

- Determine appropriate sensor types for each point

- Plan cable routing from sensors to master block

Common Use Cases:

| Application | Sensor Type | Example IFM Models |

|---|---|---|

| Hydraulic Pressure | Pressure Sensor | PN, PT series |

| Coolant Temperature | Temperature Sensor | TN, TA series |

| Air Flow Rate | Flow Sensor | SM, SD series |

| Tool Vibration | Vibration Sensor | VSE, VSP series |

| Part Position | Distance Sensor | O1D, O5D series |

| Coolant Level | Level Sensor | LR, LK series |

| Spindle Temperature | Temperature Sensor | TN series |

Step 2: Mount Sensors

- Install sensors at measurement points

- Follow manufacturer's installation guidelines

- Ensure proper orientation (especially for flow sensors)

- Verify sensor is within operating range

Step 3: Connect M12 Cables

- Use appropriate M12 cables (4-pin or 5-pin depending on sensor)

- Connect sensor M12 connector to cable

- Route cable to master block location

- Connect cable to master block port

Step 4: Label Connections

Document each connection:

- Port number

- Sensor type

- Measurement location

- Cable routing

Data Mapping

Step 1: Verify Data Collection

- Navigate to machine page in MachineMetrics

- Go to Diagnostics tab

- Verify data items are populating with values

- Check data item names match expected format

Step 2: Configure Data Mapping

- Go to Machine Settings → Data Mapping tab

- Map IO-Link data items to MachineMetrics data types:

Example Mappings:

| IO-Link Data Item | MachineMetrics Type | Subtype |

|---|---|---|

iolink_p1_310_1337_1_humidity | SAMPLE | Custom (Humidity %) |

iolink_p1_310_1337_2_temperature | SAMPLE | TEMPERATURE |

iolink_p2_310_2001_1_pressure | SAMPLE | PRESSURE |

iolink_p3_310_2500_1_flow | SAMPLE | Custom (Flow Rate) |

- Set appropriate Component (Machine, Coolant, Hydraulic, etc.)

- Add display names if needed

- Click Save

Step 3: Configure Units (If Needed)

- Note the units for each sensor from datasheet

- Include units in display names if not automatically included

- Example: "Coolant Temperature (°C)" or "Hydraulic Pressure (bar)"

Step 4: Set Up Alerts (Optional)

- Navigate to Automations & Workflows

- Create alerts based on sensor thresholds:

- High temperature warnings

- Low pressure alerts

- Vibration limit notifications

Troubleshooting

Connection Issues

Problem: Cannot Connect to Master Block

Possible causes:

- Incorrect IP address

- Network connectivity issue

- Wrong port used (IoT port vs EtherNet/IP port)

- Firewall blocking communication

Solutions:

- Verify IP address is correct (check IFM configuration software)

- Test network connectivity with ping

- Verify IoT port is used (not EtherNet/IP or Modbus port)

- Check that IoT port is assigned static IP

- Verify Edge device and master block are on same network/subnet

Problem: Intermittent Connection

Possible causes:

- Network instability

- DHCP IP address changing (if not static)

- Cable issues

Solutions:

- Use static IP address (not DHCP)

- Check network cable quality

- Verify network switch port is functioning

- Monitor network latency with continuous ping

Sensor Detection Issues

Problem: Sensors Not Detected

Possible causes:

- Sensor not properly connected

- Port not set to IO-Link mode

- Incompatible sensor

- Faulty cable

Solutions:

- Verify sensor connection (check M12 connector)

- Check port mode in IFM configuration software (must be IO-Link)

- Verify sensor is IO-Link compatible (check datasheet)

- Test with different M12 cable

- Try sensor on different port

Problem: Sensor Detected But No Data

Possible causes:

- IODD file not found

- Sensor in error state

- Process data configuration incorrect

Solutions:

- Check MachineMetrics adapter logs for IODD errors

- Verify sensor status LED (if present)

- Check sensor configuration in IFM software

- Try manual configuration with sensor datasheet

- Contact MachineMetrics support for IODD file availability

Data Issues

Problem: Data Values Incorrect

Possible causes:

- Missing or incorrect gradient/offset

- Wrong data type (int vs uint)

- Incorrect bit offset or length

Solutions:

- Verify gradient and offset from sensor datasheet

- Check data type matches sensor specifications

- Review manual configuration for typos

- Compare raw values in IFM software vs MachineMetrics

- Apply correct scaling factors

Problem: Data Items Not Appearing

Possible causes:

- Auto-configuration failed

- IODD file unavailable

- Data items not exported

Solutions:

- Check adapter logs for errors

- Verify IODD file exists for your sensor

- Try manual configuration

- Ensure data-items list includes sensor names

- Check if sensor is in IODD library

Master Block Issues

Problem: Master Block Not Responding

Possible causes:

- Power loss

- Network configuration lost

- Firmware issue

Solutions:

- Check power supply to master block

- Verify power LED is illuminated

- Reconfigure network settings with IFM software

- Reset master block to factory defaults (last resort)

- Update master block firmware if available

Additional Resources

MachineMetrics Resources:

- Transform Adapter Scripts Guide - Advanced data transformation

- Machine Settings Guide - Configure data mapping

- Connectivity Overview - Compare connectivity methods

IFM Resources:

- IFM Website: https://www.ifm.com

- IFM Software Downloads: https://www.ifm.com/us/en/category/095_010_010

- IFM Sensor Catalog: https://www.ifm.com/us/en/products

- IO-Link Technology Overview: https://www.ifm.com/us/en/shared/technologies/io-link

IO-Link Standard:

- IO-Link Technology: https://io-link.com/

- IO-Link Specification: IEC 61131-9

- IODD File Repository: https://ioddfinder.io-link.com/

Related Guides:

- Edge Device Setup - Configure MachineMetrics Edge

- Network Requirements - Firewall configuration

Getting Help

MachineMetrics Support:

- Email: support@machinemetrics.com

- Phone: 844-822-0664

- Support Portal: https://support.machinemetrics.com

Before Contacting Support:

- Note IFM master block model number

- Document connected sensor models and port numbers

- Verify network configuration (IP address, connectivity)

- Capture screenshots of IFM configuration software

- Note Vendor ID and Device ID for problematic sensors

- Check adapter logs in MachineMetrics

Information to Provide:

- IFM master block model and firmware version

- List of connected sensors (make, model, port number)

- Network configuration (IP address, subnet, gateway)

- Adapter configuration (YAML)

- Description of issue and troubleshooting steps taken

- Screenshots of IFM software showing sensor status

For IODD Issues:

- Provide Vendor ID and Device ID

- Note sensor manufacturer and model number

- Include sensor datasheet (if available)

- Describe expected vs actual data values