OPC-UA Connectivity Guide

- Overview

- Compatible Machines

- Prerequisites

- Understanding OPC-UA

- Physical Connection

- Enabling OPC-UA on Your Machine

- Adding the Machine in MachineMetrics

- Configuring Data Collection

- Sample Configurations

- Certificate Management

- OEM-Specific Notes

- Troubleshooting

- Best Practices

- Additional Resources

- Getting Help

Overview

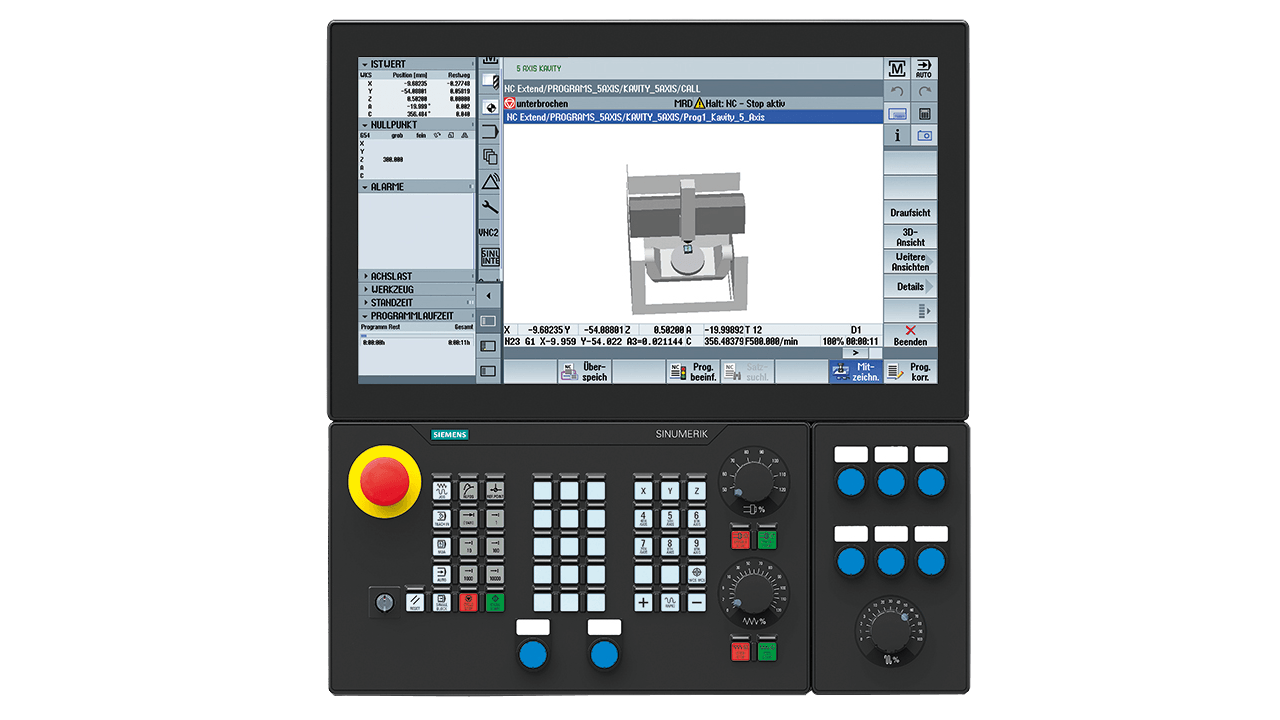

Siemens 840D sl CNC control panel. Siemens CNC controls (840D sl) use OPC-UA for connectivity, while 840D PL controls require BFC Gateway or I/O. Brother D-Series machines also use OPC-UA.

What is OPC-UA?

OPC-UA (Open Platform Communications Unified Architecture) is a platform-independent, service-oriented architecture for secure and reliable exchange of data in industrial automation. It's an industry standard that ensures seamless information flow among devices from multiple vendors.

Key Characteristics:

- Platform-independent (Windows, Linux, embedded systems)

- Secure communication (encryption, authentication, certificates)

- Rich data modeling capabilities

- Service-oriented architecture

- Maintained by the OPC Foundation

Important Note: Unlike MTConnect or FOCAS, OPC-UA does not standardize the meaning of data points. Each machine make, model, and configuration can have different data structures. This means OPC-UA connections require more initial configuration but provide great flexibility.

Why Use OPC-UA?

When OPC-UA is the Best Choice:

- Machine/controller natively supports OPC-UA

- Need secure, encrypted communication

- Connecting PLCs or automation equipment

- Equipment doesn't support other protocols (FOCAS, MTConnect)

- Connecting diverse equipment types (welders, presses, robots)

Advantages:

- Industry-standard protocol

- Secure by design

- Rich data modeling

- Platform-independent

- Widely supported by automation vendors

Challenges:

- Requires understanding of machine's data model

- Need data map/tag list from manufacturer

- More complex initial configuration

- Certificate management may be required

Who This Guide is For

This guide is for:

- Engineers connecting OPC-UA-capable equipment

- IT personnel configuring secure OPC-UA connections

- Anyone connecting Siemens, Brother, or other OPC-UA machines

- PLC programmers and automation specialists

- System integrators working with diverse equipment

Compatible Machines

Common OPC-UA Equipment

CNC Machine Controls:

- Siemens Sinumerik 828D / 840D SL (with OPC-UA license)

- Brother D-Series CNC machines

- Some FANUC robots

- Various DMG MORI machines

- Other modern CNC controls

Manufacturing Equipment:

- Bystronic laser cutters and press brakes

- Industrial robots (ABB, KUKA, Fanuc)

- Automated assembly equipment

- Process machinery

Automation & PLCs:

- Siemens S7 PLCs

- Allen-Bradley (via gateway)

- Beckhoff controllers

- B&R Automation

- Many others

Third-Party OPC-UA Servers:

- Kepware (common gateway/adapter)

- MatrikonOPC

- Softing OPC servers

- Custom implementations

Checking for OPC-UA Support

Check with Manufacturer:

- Consult machine documentation

- Contact machine tool builder support

- Verify control version and options installed

- Ask if OPC-UA license is required

Check on Machine:

- Look for OPC-UA in control settings/menus

- Check license page for OPC-UA option

- Review control software version for OPC-UA support

Verify with Tools:

- Use OPC-UA client software to attempt connection

- Try connecting to

opc.tcp://[machine-ip]:4840 - Common ports: 4840, 4855, 49320, 56000 (varies by implementation)

Prerequisites

Hardware Requirements

- Machine or equipment with OPC-UA server capability

- MachineMetrics Edge device (deployed and activated)

- Ethernet cable (CAT5/CAT6)

- Network access between machine and Edge device

Software Requirements

- OPC-UA server enabled on machine/controller

- OPC-UA license (if required by manufacturer)

- OPC-UA client tool for browsing (UaExpert, opcua-commander, etc.)

- Data map or tag list from machine manufacturer

Information Needed

Before starting, gather:

- Machine IP address

- OPC-UA port number (typically 4840)

- Username and password (if authentication required)

- Security mode and policy (if applicable)

- Data map/tag list showing:

- Node IDs for relevant data

- What each tag represents (status, part count, etc.)

- Data types and units

- Certificate requirements (if any)

Understanding OPC-UA

Architecture

OPC-UA uses a client-server model:

Machine/Controller (OPC-UA Server)

↓

Network (TCP/IP)

↓

MachineMetrics Edge Device (OPC-UA Client)

↓

MachineMetrics Cloud

Components:

- Server: Runs on machine/controller, exposes data

- Client: MachineMetrics Edge device, reads data

- Address Space: Hierarchical structure of available data nodes

- Nodes: Individual data points with unique identifiers

Data Structure

OPC-UA data is organized in a tree-like address space with nodes.

Node ID Format:

ns=2;s=/Channel/State/progStatus(string identifier)ns=3;i=1001(integer identifier)ns=4;g=A7B3...(GUID identifier)

Where:

ns= namespace indexs= string identifieri= integer identifierg= GUID identifier

Data Types:

Simple Types:

- String, Boolean, DateTime

- Double, Float, Int32, Int64

- Guid, LocalizedString

Complex Types:

- Objects (structures with properties)

- Enumerations (predefined value sets)

- Arrays (ordered collections)

Example:

Node: ns=2;s=/Channel/State

↳ Property: progStatus (Int32)

↳ Property: opMode (String)

↳ Property: actParts (Int32)

Security Modes

OPC-UA supports multiple security configurations:

| Mode | Description | Use Case |

|---|---|---|

| None | No encryption, no authentication | Testing, internal networks only |

| Sign | Data is signed (integrity) | Standard security |

| SignAndEncrypt | Data signed and encrypted | High security environments |

Common Security Policies:

- None - No security

- Basic128Rsa15 - Older security standard

- Basic256 - Common standard

- Basic256Sha256 - Modern, recommended standard

Browsing OPC-UA Servers

Before configuring MachineMetrics, you need to browse the OPC-UA server to find relevant data nodes.

Option 1: GUI Client (Recommended for most users)

UaExpert (Free from OPC Foundation):

- Download: opcfoundation.org/products/view/uaexpert

- Windows only (7 or higher)

- Intuitive graphical interface

- Easy browsing of address space

Steps:

- Install UaExpert

- Add new server connection

- Enter endpoint URL:

opc.tcp://[machine-ip]:[port] - Connect (handle certificates if prompted)

- Browse address space to find data nodes

- Note node IDs for relevant data

Option 2: Command Line Client

uals (Python OPC-UA tools):

- Source: github.com/FreeOpcUa/python-opcua

- Cross-platform (Windows, Linux, macOS)

- Prints tree-like structure in plaintext

Usage:

uals -u opc.tcp://[address]:[port] -i [namespace_id] -d [tree_depth]

opcua-commander (Interactive terminal client):

- Source: github.com/node-opcua/opcua-commander

- Requires Node.js

- Interactive browsing capability

Physical Connection

Step 1: Connect Ethernet Cable

- Plug cable into machine's Ethernet port

- For Siemens CNC: Typically X130 (company network port)

- For Brother: Standard network port on control

- Verify link lights

🔴 CRITICAL WARNING for Siemens CNC Machines:

- Always check your machine documentation for the correct port address

- Port designation varies by machine tool builder (X130 is common, but not universal)

- These machines have complex internal networks and PROFIBUS

- Connecting to the wrong port can BRICK the machine

- NEVER connect to system network ports (192.168.214.x or 192.168.215.x ranges)

- When in doubt, contact your machine tool builder

Step 2: Configure Network

- Set static IP on machine (recommended)

- Document IP address, subnet, gateway

- Ensure machine and Edge device are on same subnet or properly routed

Step 3: Test Connectivity

- Ping machine IP from Edge or computer

- Verify response

- Check firewall allows OPC-UA port

Enabling OPC-UA on Your Machine

Generic OPC-UA Setup

For machines with OPC-UA capability:

-

Verify License

- Check if OPC-UA option is licensed

- Purchase/install license if needed

- Verify license is activated

-

Enable OPC-UA Server

- Access machine settings/configuration

- Look for OPC-UA, network, or communication settings

- Enable OPC-UA server function

-

Configure Port

- Default: 4840

- Some implementations use different ports

- Note the port for later

-

Set Authentication

- Create username and password (if required)

- Or enable anonymous access (testing only)

- Document credentials

-

Configure Security

- Select security mode (None, Sign, SignAndEncrypt)

- Select security policy (None, Basic256, Basic256Sha256)

- Balance security needs with compatibility

-

Restart/Reboot

- Changes typically require restart

- Follow manufacturer instructions

Siemens 828/840D SL Setup

Prerequisites:

- SINUMERIK Operate installed

- OPC-UA license: 6FC5800-0AP67-0YBO (purchased from Siemens)

- Manufacturer access level password

- Static IP from your IT team

Compatibility:

| CNC Software Version | OPC-UA Version Supported |

|---|---|

| 4.5 | V2.2 and V3.0 SP1 |

| 4.07 SP2-SP5 | V2.2 and V3.0 SP1 |

| 4.08 SP2-SP3 | V2.2 and V3.0 SP1 |

| 4.92 and 4.92 HF2 | V3.0 SP1 |

Step 1: Enable Manufacturer Access

- Select Startup area (🔧 Setup icon)

- Press Password → Set password

- Enter manufacturer password:

SUNRISE - Press OK

- Status bar should show: "Access level: Manufacturer"

Note: If rejected, the OEM may have changed the default password. Contact machine builder.

Step 2: Set License

- Go to Startup

- Press Licenses soft key

- Navigate to Access MyMachine / OPC UA

- Check the box under Set

- If license not available: Purchase from Siemens

Step 3: Set Company Network IP (X130 Port)

🔴 CRITICAL WARNING:

- X130 is the most common port, but always verify with your machine documentation

- Different machine tool builders use different port designations

- These machines have complex internal networks and PROFIBUS

- Connecting to the wrong port can BRICK your machine

- NEVER modify system network (192.168.214.x or 192.168.215.x ranges)

- When in doubt, contact your machine tool builder before proceeding

- Select Diagnostics

- Press menu forward key → Choose Bus TCP/IP

- Select TCP/IP diagnostics → TCP/IP config

- Select interface X130 (or your machine's designated company network port - verify in documentation)

- Press Change

- Set Address Type = Manual (for static IP)

- Enter network settings:

- IP Address: Assigned by IT team

- Subnet Mask: From IT team

- Gateway: Only if needed for routing outside subnet

- Press OK

- Restart the control (mandatory for changes to take effect)

Physical Port Location:

- On SINUMERIK 828D: Typically rear-panel Ethernet port labeled X130

- Verify port designation in your machine documentation

- Use shielded CAT5e/CAT6 cable

- Connect directly to company network switch

Step 4: Configure OPC-UA Server

-

In Startup area, navigate to: Network → OPC UA → Setting → Change

-

Connection Settings:

- Verify Company network is selected

- Confirm IP address (your Company IP)

- TCP Port:

4840(default, leave unchanged)

-

Authentication:

- Admin User: Create username (e.g.,

OpcUaClient) - Password: Set secure password (needed for MachineMetrics connection)

- Allow anonymous access: Uncheck (for security)

- Accept certificates automatically: Check only for initial testing

- Admin User: Create username (e.g.,

-

Activation:

- Check Activate OPC UA

-

Press OK → Save PCU settings

-

Restart OPERATE for changes to take effect

Step 5: Verify Connectivity

- From PC on same network:

ping [machine-ip] - In Startup → Network → OPC UA → Status

- Confirm server lists Company IP (e.g.,

10.1.0.46:4840) - Should show Status: OK

Step 6: Accept Certificates

When MachineMetrics Edge first connects:

- Go to Startup → Network → OPC UA → Certificates

- Under "Pending Certificates", select the client certificate

- Press Accept

- Status page should show connected clients

Step 7: Return to Normal Access Level

- Go to Startup → Password → Set password

- Press Cancel or enter user-level password

- Status bar should return to "Access level: User"

Additional Resources:

Brother D-Series Setup

Step 1: Access Communication Menu

- From main screen, press DATABANK soft key

- Select 7. Communication parameter

- Navigate to Ethernet/FTP settings

Step 2: Configure Static IP

⚠️ Important: Brother controls use special numeric format for IP addresses.

- 0202 - Use DHCP → Set to

No - 0203 - IP address → Enter IP as 12-digit number

- Standard format:

172.22.3.34 - Brother format:

172022003034(no dots!) - Pad each octet to 3 digits

- Standard format:

- 0204 - Mask bit → Typically

255.255.255.0

Step 3: Configure Network Access

- 0004 - Display slave command alarm → Set to

No - 0216 - Restrict Ethernet access → Set to

No

Step 4: Enable OPC-UA

Navigate to final Ethernet/FTP menu screen:

- 0235 - OPC UA server function → Set to

Valid - 0236 - Security communication for client → Set to

2: Type2 - 0237 - OPC UA security communication → Set security level:

0: No- No username/password (simplest)1-5- RSA/AES encryption with authentication

Step 5: Save Settings

- Press Save and end (bottom left)

- Or use Overwrite save to continue editing

⚠️ Critical: If you don't save, all changes are lost on shutdown/reboot.

Step 6: Verify Connectivity

- Press MONITR soft key

- Select 3. Communication monitor

- Look for

Ethernet (OPC UA)in Port column - Message column should show:

Sending completedData sentOutput request received

Step 7: Check Ethernet Information

- In MONITR menu, select Ethernet information

- Verify displays:

- IP Address (as configured)

- Subnet Mask

- Gateway

- MAC Address

- DHCP status

Connection String for MachineMetrics:

opc.tcp://[ip-address]:4840

Example: opc.tcp://10.103.112.62:4840

Sample Script: Brother OPC-UA Sample

Bystronic Setup

Step 1: Enable OPC-UA

- Navigate to Modules → Administration → Advanced Settings

- Find OPC-UA setting

- Enable OPC-UA server

Step 2: Open Firewall Ports

Port 56000 (both TCP and UDP) must be open on both:

- Brake panel PC

- Server

Note: For network-level firewall configuration and Edge device requirements, see the Network Requirements Guide.

Creating Firewall Rules:

For TCP Port:

- Open Control Panel on machine/server

- System and Security → Windows Defender Firewall

- Advanced Settings → Inbound Rules

- Actions (right side) → New Rule

- Select Port → Next

- Select TCP → Enter

56000for Specific Local Port → Next - Select Allow the connection → Next

- Select Domain, Private, Public → Next

- Enter name:

Bystronic56000TCPPort→ Finish

For UDP Port:

- Actions → New Rule

- Select Port → Next

- Select UDP → Enter

56000→ Next - Allow the connection → Next

- Select all profiles → Next

- Enter name:

Bystronic56000UDPPort→ Finish

Step 3: Reboot

Reboot the entire machine (not just the PC) for changes to take effect.

Connection Port: 56000

Adding the Machine in MachineMetrics

Once OPC-UA is enabled and network is configured:

Step 1: Browse OPC-UA Server First

Before adding in MachineMetrics, use an OPC-UA client to:

- Verify you can connect to the server

- Browse available data nodes

- Document node IDs for relevant data

- Create data map/tag list

Step 2: Log into MachineMetrics

- Navigate to Assets → Machines

- Click Add Machine

Step 3: Enter Machine Details

- Machine Name: Descriptive name

- Make: Manufacturer

- Model: Machine model

- Select Edge Device: Choose your Edge

Step 4: Configure OPC-UA Adapter

- Adapter Type: Select OPC-UA

- Connection String:

opc.tcp://[ip-address]:[port]- Example:

opc.tcp://192.168.1.100:4840

- Example:

- Username: If authentication required

- Password: If authentication required

- Security Mode: None, Sign, or SignAndEncrypt

- Security Policy: None, Basic256, Basic256Sha256

- Click Test Connection

Step 5: Verify Connection

- Test should return success

- If fails: Check connection string, credentials, firewall

- Click Save when successful

Step 6: Configure Adapter Script

This is where you define which data nodes to collect.

- See OPC-UA Adapter Scripts section

- Use YAML format to define tags, variables, and data items

Configuring Data Collection

Available Data Items

Data available through OPC-UA varies widely by implementation. Common items include:

Machine Status:

- Execution state (running, idle, stopped)

- Controller mode (AUTO, MDI, MANUAL)

- Alarm status

Program Information:

- Program name

- Line number

- Block counter

Production Metrics:

- Part count (various methods)

- Cycle time

- Run time

Machine Parameters:

- Spindle speed and load

- Feed rate and override

- Axis positions

- Tool number

Alarms & Diagnostics:

- Active alarms with codes

- Alarm history

- Diagnostic values

Custom Data:

- Process parameters

- Quality measurements

- Automation status

- Equipment-specific values

OPC-UA Adapter Scripts

MachineMetrics uses YAML configuration to map OPC-UA data to our standard model.

Script Structure:

version: 2

username: your-username # If required

password: your-password # If required

security-mode: Sign # None, Sign, or SignAndEncrypt

security-policy: Basic256Sha256 # or Basic256, Basic128Rsa15, None

tags:

# Define data nodes to monitor

variables:

# Transform and model data

data-items:

# Specify which items to send to MachineMetrics

Tags Configuration

Tags define references to specific nodes in the OPC-UA address space.

Simple Tag (Direct Value):

tags:

spindle-speed:

path: ns=2;s=/Nck/Spindle/actSpeed

program-name:

path: ns=2;s=/Channel/ProgramInfo/progName

Complex Type Tag (Object with Properties):

tags:

part-quantity:

path: ns=2;s=/Laser/CurrentPlan

property: partQuantity

This retrieves the partQuantity property from the CurrentPlan object.

Variables and Transformations

Variables transform tag values into MachineMetrics standard model.

Pass-Through (No Transformation):

variables:

spindle-rpm:

- source: spindle-speed

State Transformation (Conditional Logic):

variables:

execution:

- source: prog-status

- state:

- INTERRUPTED: this == 1

- STOPPED: this == 2 or this == 5

- ACTIVE: this == 3 or this == 4

- READY: true # Fallback

Count on Value Change:

variables:

part-count:

- source: part-quantity

- value-change

- count

Mathematical Operations:

variables:

execution:

- source: laser-power

- state:

- ACTIVE: this > 0

- READY: true

Data Mapping

After adapter script is configured, map data items in MachineMetrics:

Step 1: Edit Machine

- Assets → Machines → [Your Machine]

- Go to Data Mapping tab

- Click Refresh List to see new items

Step 2: Map Each Data Item

For each data item from your script:

- Select Type (e.g., "Part Count", "Sample", "Event")

- Select Subtype (e.g., "Actual", "Speed", "Status")

- Assign Component (e.g., "Spindle", "Controller")

- Add Display Name (human-readable description)

Step 3: Save Mappings

- Review all mappings

- Click Save Changes

- Data will now flow to MachineMetrics dashboards and reports

Sample Configurations

Siemens 840D Sample Script

version: 2

username: OpcUaClient

password: YourSecurePassword

security-mode: Sign

security-policy: Basic256Sha256

tags:

tool-group:

path: ns=2;s=/Channel/State/actToolIdent

tool-num:

path: ns=2;s=/Channel/State/actTNumber

line-number:

path: ns=2;s=/Channel/ProgramInfo/actLineNumber

spindle-load:

path: ns=2;s=/Nck/Spindle/driveLoad

prog-status:

path: ns=2;s=/Channel/State/progStatus

controller-op-mode:

path: ns=2;s=/Bag/State/opMode

spindle-speed:

path: ns=2;s=/Nck/LogicalSpindle/actSpeed

last-alarm-number:

path: ns=2;s=/Nck/LastAlarm/alarmNo

feed-rate:

path: ns=2;s=/Channel/MachineAxis/actFeedRate

prog-name:

path: ns=2;s=/Channel/ProgramInfo/progName

act-parts:

path: ns=2;s=/Channel/State/actParts

feedrate-ovr:

path: ns=2;s=/Channel/MachineAxis/feedRateOvr

variables:

execution:

- source: prog-status

- state:

- INTERRUPTED: this == 1

- STOPPED: this == 2 or this == 5

- ACTIVE: this == 3 or this == 4

- READY: true

controller-mode:

- source: controller-op-mode

- state:

- MANUAL: this == 0

- MANUAL_DATA_INPUT: this == 1

- AUTOMATIC: this == 2

data-items:

- execution

- controller-mode

- spindle-speed

- spindle-load

- feed-rate

- feedrate-ovr

- last-alarm-number

- line-number

- tool-group

- tool-num

- prog-name

- act-parts

Note: This script is valid for Siemens 828/840D SL controls. Node paths may differ for other machines.

Brother Sample Script

Sample configuration for Brother D-Series CNC machines available from MachineMetrics support.

Connection:

- Port: 4840

- Security: Typically Type2

- Format IP correctly in control (12-digit numeric)

Generic Laser Cutter Script

version: 2

tags:

part-quantity:

path: ns=2;s=Laser.CurrentPlan

property: partQuantity

laser-power:

path: ns=2;s=Laser.CurrentLaserPower

cut-state:

path: ns=2;s=Laser.CurrentCutState

variables:

part-count:

- source: part-quantity

- value-change

- count

execution:

- source: laser-power

- state:

- ACTIVE: this > 0

- READY: true

data-items:

- execution

- part-count

- part-quantity

- cut-state

Explanation:

part-count: Counts each timepart-quantitychangesexecution: ACTIVE when laser power > 0, otherwise READY- Direct pass-through for

part-quantityandcut-state

Certificate Management

Understanding Certificates

OPC-UA uses X.509 certificates for security:

- Server Certificate: Identifies the machine/server

- Client Certificate: Identifies MachineMetrics Edge

- Both sides must trust each other's certificates

Accepting Certificates

On Siemens Controls:

- Startup → Network → OPC UA → Certificates

- Pending certificates appear when client first connects

- Select client certificate → Accept

- MachineMetrics Edge must also trust server certificate (usually automatic)

On Other Controls:

- Process varies by manufacturer

- Check control documentation

- May auto-accept or require manual approval

Testing During Setup:

- Can enable "Accept certificates automatically" initially

- Disable after confirming connection works

- For production, use proper certificate validation

Certificate Errors:

- Usually appear as connection failures

- Check that certificates are accepted on both sides

- Verify certificate hasn't expired

- Check system time/date on both devices

OEM-Specific Notes

Siemens Sinumerik 828/840D SL

Key Points:

- Requires OPC-UA license purchase

- Typically uses X130 port (company network) - but always verify with your machine documentation

- CRITICAL: Different machine tool builders use different port designations

- Connecting to the wrong port can brick the machine - these machines have complex internal networks and PROFIBUS

- Never modify system network (192.168.214.x / 215.x)

- Default manufacturer password: SUNRISE

- Port: 4840

- Requires restart after configuration

Version-Specific Guides:

- Different Operate versions have slightly different menus

- See Additional Resources section for version-specific PDFs

- Always verify your Operate version first

Finding Operate Version:

- Startup area → Version or Version display soft key

- Look for "SINUMERIK Operate Version" (e.g., 4.7 SP2 HF3)

Brother D-Series CNC

Key Points:

- IP address format is 12-digit numeric (not standard dot notation)

- Port: 4840

- Security Type2 common

- Must save settings or they're lost

- Communication monitor confirms OPC-UA activity

IP Format Examples:

172.22.3.34→ Enter as17202200303410.1.50.200→ Enter as010001050200- Pad each octet to exactly 3 digits

Verification:

- Use Communication monitor to verify OPC-UA activity

- Ethernet information screen confirms IP settings

Bystronic

Key Points:

- Port: 56000 (not standard 4840)

- Requires both TCP and UDP firewall rules

- Must reboot entire machine (not just PC)

- Enable in Modules → Administration → Advanced Settings

Unique Port:

- Bystronic uses port 56000 instead of standard 4840

- Must open both TCP and UDP for this port

Fanuc Robots

Key Points:

- Fanuc robots support OPC-UA

- Typically port 4880

- Requires network configuration on robot controller

- Data structure varies by robot model

Contact:

- Fanuc robot support for specific configuration

- MachineMetrics support for adapter script assistance

Other OPC-UA Equipment

Generic Process:

- Verify OPC-UA is licensed and enabled

- Determine port number

- Get data map from manufacturer

- Use OPC-UA client to browse server

- Create adapter script based on relevant nodes

- Work with MachineMetrics support for script development

Troubleshooting

Connection Issues

Problem: Can't connect to OPC-UA server

Diagnostic Steps:

-

Verify Network Connectivity

- Ping machine IP from Edge or computer

- If ping fails: network problem

- If ping succeeds: OPC-UA configuration issue

-

Test with OPC-UA Client

- Use UaExpert or similar tool

- Try connecting from a computer on same network

- Try endpoint:

opc.tcp://[machine-ip]:[port] - If client can't connect: OPC-UA not properly enabled

-

Verify Port Number

- Common ports: 4840, 56000 (Bystronic), 49320 (Kepware), 4880 (Fanuc robots)

- Check machine documentation

- Try different ports if unsure

-

Check Firewall

- Windows Firewall on control may block OPC-UA port

- Temporarily disable to test (re-enable after)

- Or create firewall rule for OPC-UA port

-

Verify OPC-UA Service

- Check that OPC-UA server is enabled on machine

- May be in license settings, network settings, or services

Authentication Failures

Problem: Connection fails with authentication error

Solutions:

-

Verify Credentials

- Double-check username and password

- Case-sensitive

- No extra spaces

-

Check Authentication Settings

- Verify username/password is configured on machine

- Some machines require creating OPC-UA user account

- Check if anonymous access is enabled (for testing)

-

Security Mode Mismatch

- Verify security mode matches machine configuration

- Try None, Sign, then SignAndEncrypt

- Must match what machine expects

-

Security Policy Mismatch

- Verify policy matches machine capability

- Try None, then Basic256, then Basic256Sha256

- Older equipment may only support Basic128Rsa15

Certificate Errors

Problem: Certificate validation failures

Solutions:

-

Accept Certificates

- On machine: Accept MachineMetrics Edge certificate

- On Edge: Usually accepts automatically

- Check pending certificates on machine

-

Check System Time

- Certificates have validity periods

- If machine or Edge time is wrong, certificates fail

- Sync time via NTP

-

Regenerate Certificates

- May need to clear and regenerate

- Contact MachineMetrics support for assistance

-

Temporary: Disable Certificate Validation

- For testing only

- Enable "Accept certificates automatically"

- Properly configure for production

No Data Appearing

Problem: Connected but no data in MachineMetrics

Solutions:

-

Check Adapter Script

- Verify YAML syntax is correct

- Ensure tags reference valid node IDs

- Test node IDs in OPC-UA client first

-

Verify Data Mapping

- Assets → Machines → Data Mapping

- Ensure data items from script are mapped

- Check for unmapped items

Part Count Issues

Problem: Part counts not incrementing or incorrect

⚠️ CRITICAL FIRST STEP: Verify Machine is Counting Parts

Before troubleshooting MachineMetrics configuration, verify the machine itself is incrementing its internal part counter.

MachineMetrics reads the machine's native part counter via OPC-UA. If the machine isn't counting parts, MachineMetrics cannot report them. Without additional scripting or configuration, MachineMetrics relies entirely on the machine's internal part count signal exposed via OPC-UA.

Check Machine Part Counter:

- Look at the machine's control screen or HMI

- Find the part counter display (varies by machine/OEM)

- Run a cycle

- Verify the counter increments on the machine itself

If the machine counter is NOT incrementing:

- This is a machine configuration issue, not a MachineMetrics issue

- Machine is not configured to count parts

- Consult machine manual or OEM for part counting configuration

- May require enabling part counting in machine settings

If the machine counter IS incrementing but MachineMetrics shows zero:

- This is a MachineMetrics or OPC-UA configuration issue

- Continue to diagnostic steps below

Diagnostic Steps:

-

Verify Part Count Tag in OPC-UA

- Use OPC-UA client (UaExpert) to browse server

- Find part count tag/node ID

- Watch tag value while running machine

- If tag doesn't increment in OPC-UA client: Machine not exposing part count

-

Check Adapter Script

- Verify part count tag is referenced in YAML script

- Ensure node ID is correct (copy from OPC-UA client)

- Verify

data-itemsincludes part count variable

-

Check Data Mapping

- Assets → Machines → Data Mapping

- Ensure part count data item is mapped

- Type should be "Part Count"

-

Test with OPC-UA Client

- Connect to machine with UaExpert

- Monitor part count tag in real-time

- Run a cycle on machine

- If tag increments in UaExpert but not MachineMetrics: Configuration issue

- If tag doesn't increment in UaExpert: Machine not counting parts

Common OEM-Specific Notes:

- Bystronic: Look for

Production.PartCounteror similar in OPC-UA tree - Siemens: Check

DB(Data Block) for part count variable - Fanuc Robots: May require program command to increment counter (e.g.,

R[1]=R[1]+1)

-

Check Machine Status

- Machine may need to be running to generate some data

- Verify OPC-UA server is active

-

Review Edge Logs

- Settings → Edge Devices → Logs

- Look for OPC-UA errors

- Check for node ID errors or parsing issues

-

Test with Simple Script First

- Start with minimal configuration

- Add one or two tags

- Verify those work before adding more

Firewall Issues

Problem: Can connect locally but not from network

See Also: Network Requirements Guide for Edge device firewall requirements.

Solutions:

-

Windows Firewall (On Machine)

- Open Windows Firewall settings

- Create inbound rule for OPC-UA port

- Allow TCP and UDP

- Apply to all profiles

-

Network Firewall

- Work with IT team

- Ensure OPC-UA port allowed between machine and Edge

- May need exception for specific IP addresses

-

Test Locally First

- On machine control, use OPC-UA client

- Connect to

opc.tcp://localhost:[port] - If this works but remote doesn't: firewall

Best Practices

Planning:

- Browse OPC-UA server before configuration

- Create comprehensive data map with manufacturer's help

- Start with essential data items, add more later

- Document all node IDs and their meanings

Security:

- Use strong passwords for OPC-UA accounts

- Use Sign or SignAndEncrypt security mode

- Properly manage certificates

- Don't use anonymous access in production

- Use dedicated network for machine connectivity

Network:

- Use static IP addresses

- Document IP, port, and credentials

- Test connectivity before full configuration

- Keep machine firewall rules documented

Configuration:

- Start with simple adapter script

- Test incrementally (add tags one at a time if issues)

- Validate data accuracy against machine display

- Keep backup of working configurations

Data Mapping:

- Use descriptive display names

- Map all relevant data items

- Assign proper types and subtypes

- Review mappings for accuracy

Maintenance:

- Monitor for connection errors in Edge logs

- Keep OPC-UA server software updated

- Review certificate expiration dates

- Document any configuration changes made

Working with Manufacturers:

- Request complete data map/node list

- Ask for recommended node IDs for status, count, etc.

- Get clarification on data types and units

- Request sample configurations if available

Additional Resources

OPC Foundation:

- Official website: opcfoundation.org

- OPC-UA specification

- Client tool downloads

- Training and certification

OPC-UA Client Tools:

- UaExpert (GUI, Windows)

- python-opcua (Command line)

- opcua-commander (Interactive terminal)

Standards:

- UMATI (Universal Machine Tool Interface)

- MTConnect OPC-UA Companion Specification

- Industry-specific OPC-UA standards (emerging)

MachineMetrics Resources:

- Machine Connectivity Overview

- Knowledge Base: https://support.machinemetrics.com

- OPC-UA adapter script examples (contact support)

Getting Help

Before Contacting Support

Gather this information:

-

Machine Details

- Make, model, serial number

- Control type and version

- OPC-UA license status

-

Network Configuration

- Machine IP address and port

- Connection string used

- Can you ping the machine?

-

OPC-UA Browsing Results

- Can you connect with UaExpert or other client?

- What data nodes are available?

- Node ID examples

-

Current Configuration

- Adapter script (YAML)

- Data mapping configuration

- Any error messages from Edge logs

-

Authentication & Security

- Security mode and policy used

- Username (don't include password in emails)

- Certificate status

Contact Options

MachineMetrics Support:

- Email: support@machinemetrics.com

- Include all information above

- Attach screenshots

- Include adapter script (sanitize passwords)

Machine Manufacturer:

- For OPC-UA license/enablement

- For data map and node ID documentation

- For control-specific configuration

- For software updates

Solution Delivery Manager (SDM):

- For deployment planning

- For adapter script development assistance

- For best practices and optimization

OPC Foundation:

- For protocol questions

- For client tool support

- For standards documentation

Ready to connect your OPC-UA machine?

- Verify OPC-UA support and licensing

- Browse OPC-UA server to identify data nodes

- Configure network and enable OPC-UA

- Create adapter script for your machine

- Add machine in MachineMetrics

- Map data items

- Verify data flow

Questions? Contact support@machinemetrics.com with your machine details and data map.

Need adapter script help? MachineMetrics support can assist with creating custom OPC-UA adapter scripts based on your machine's data structure.