System Settings Guide

Overview

What are System Settings?

System Settings is the central configuration area for MachineMetrics. This is where administrators configure company-wide settings, manage users, set up machine groups and schedules, configure downtime and quality categories, and integrate with external systems.

Key Capabilities:

- Configure user profiles and notification preferences

- Set company-wide defaults and goals

- Manage users and assign roles

- Organize machines into groups

- Define shift schedules

- Configure downtime and quality categories

- Manage operators and ShopPulse Interface settings

- Generate API keys for integrations

- Configure Single Sign-On (SSO)

Who Uses System Settings:

- IT Admins: Full access to all settings, including SSO and API keys

- Executives: Access to all settings

- Managers: Access to most settings, including user management

- Supervisors: Limited access (view only for most settings)

Accessing System Settings

Opening System Settings

Step-by-Step:

- Look at the bottom left corner of the MachineMetrics interface

- Click the gear icon (⚙️)

- Settings menu appears from the bottom of the screen

Settings Menu Structure: The left sidebar contains all settings categories:

- Profile

- Company

- Users

- Machine Groups

- Machine Schedules

- Activities

- Auto Setup

- Downtimes

- Quality

- Operators

- ShopPulse Interface

- API Keys

- Integrations

- Single Sign-On

- Edge Management

[Recommended Image]: Screenshot of Settings menu with gear icon highlighted and menu open

Profile Settings

What is Profile?

Profile contains your personal user settings, including notification preferences and working hours.

Access: Settings → Profile

Mobile Number

Purpose: Receive text notifications from workflows and alerts.

Configuration:

- Enter your mobile number (with country code)

- Format:

+1-555-123-4567 - Click Save

Use Case: Receive urgent alerts via text message when workflows trigger.

Notification Preferences

How You Prefer to Be Notified: Configure how workflows and alerts reach you.

Options:

- Email: Receive notifications via email only

- Text: Receive notifications via text message only

- Email and Text: Receive notifications via both methods

- Never: Do not receive notifications

Important: By default, notification preference is set to Never. If you're not receiving workflow notifications, check this setting first.

Configuration:

- Select preferred notification method from dropdown

- Click Save

Notification Schedule

Purpose: Specify when you want to receive notifications (avoid off-hours alerts).

Configuration:

- Click Add Schedule

- Select days of week (e.g., Monday - Friday)

- Set start time (e.g., 9:00 AM)

- Set end time (e.g., 5:00 PM)

- Click Save

Example:

Working Hours: Monday - Friday, 9:00 AM - 5:00 PM

Result: Notifications only sent during these hours

Multiple Schedules:

- Add multiple schedules for different days or shifts

- Example: Monday-Friday 9-5, Saturday 8-12

Override: Workflow creators can choose to override notification times for critical alerts (sent at any time regardless of your schedule).

[Recommended Image]: Screenshot of Profile settings showing notification preferences and schedule

Company Settings

What is Company Settings?

Company Settings contains system-wide defaults and preferences that apply to all users.

Access: Settings → Company

Who Can Edit: Managers, Executives, IT Admins

Default Dashboard View

Purpose: Set which dashboard users see when logging in or navigating to dashboards.

Options:

- Utilization: Current Shift Dashboard with Utilization view

- Parts Goal: Current Shift Dashboard with Parts Goal view

- Downtime: Current Shift Dashboard with Downtime view

- OEE: Current Shift Dashboard with OEE view

Configuration: Select default view from dropdown and click Save.

Display Settings

Display "Waiting for Work":

- Enabled: Show "Waiting for Work" status when machine has no assigned operation

- Disabled: Hide this status

Display "Unknown Job":

- Enabled: Show "Unknown Job" when machine is running without assigned operation in MachineMetrics

- Disabled: Hide this status

Use Case: If you don't use Operations/APM, disable "Unknown Job" to reduce clutter.

Allow Operators to Override Job Start/End Times

Purpose: Let operators adjust job timestamps when starting/stopping operations on tablets.

Options:

- Enabled: Operators can backdate job start time (e.g., "I actually started 10 minutes ago")

- Disabled: Job timestamps always use current time

Configuration: Toggle on/off

Use Case: Enable if operators frequently forget to start operations on time. Disable to enforce strict timestamping.

Cycle Time Entry

Purpose: Define how cycle time is entered in operation definitions.

Options:

- Single Part Duration: Enter time for one part (most common)

- Full Cycle Time Duration: Enter time for complete cycle (if multiple parts per cycle)

- Parts Per Hour: Enter production rate (e.g., 30 parts/hour)

Configuration: Select from dropdown

Impact: Affects how Expected Part Time is entered when creating operations.

Operator Tracking

Purpose: Enable/disable operator login functionality on tablets.

Options:

- Enabled: Operators can log in/out on tablets, operator performance tracked

- Disabled: No operator tracking

Configuration: Toggle on/off

See Also: Operators and ShopPulse Interface Guide

Ideal Cycle Time

Purpose: Define how ideal cycle time is handled for OEE Performance calculations.

Options:

- Automatic: MachineMetrics calculates ideal cycle time from historical data

- Manual: Enter ideal cycle time manually for each operation

- Disabled: No ideal cycle time used (Performance based on expected cycle time only)

Configuration: Select from dropdown

See Also: Understanding Your Data Guide

Ignore APM Archive Operations

Purpose: Control whether APM (Automatic Production Monitoring) auto-archives operations.

Options:

- Enabled: APM ignores archived operations (won't create new runs for archived ops)

- Disabled: APM can still create runs for archived operations

Configuration: Toggle on/off

Use Case: Enable to prevent APM from reactivating old operations when program numbers are reused.

ERP Job Tracking Settings

Job Tracking Method:

Purpose: Define who controls production run creation.

Options:

- Driven by MachineMetrics: Operators or APM create production runs in MachineMetrics

- Driven by ERP: External ERP system creates/manages production runs via API

Configuration: Select from dropdown

Use Case: If integrating with ERP (e.g., IQMS, E2, JobBOSS), set to "Driven by ERP".

Default Metric Goals

Purpose: Set company-wide performance thresholds for color-coded dashboards.

Configurable Goals:

1. Utilization Goals

- Goal (Green): % or above (e.g., 85%)

- Warning (Yellow): % threshold (e.g., 70%)

- Failure (Red): Below warning threshold

2. OEE Goals

- Goal (Green): % or above (e.g., 70%)

- Warning (Yellow): % threshold (e.g., 50%)

- Failure (Red): Below warning threshold

3. Parts Goal

- Goal (Green): % or above (e.g., 100% of expected)

- Warning (Yellow): % threshold (e.g., 85%)

- Failure (Red): Below warning threshold

Configuration:

- Enter percentages for each threshold

- Click Save

Impact: Determines Performance Wheel colors on ShopPulse Interface and dashboard tile colors.

Override: Machine-specific or operation-specific goals override company defaults.

[Recommended Image]: Screenshot of Company Settings showing default goals configuration

Users Management

What is Users?

Users is where you invite colleagues to MachineMetrics and assign roles.

Access: Settings → Users

Who Can Manage: Managers, Executives, IT Admins

User Roles

Available Roles:

1. Kiosk

- Purpose: Tablets and large screen TV displays

- Access: View-only, no login required

- Use Case: Shop floor dashboards on TVs

2. Supervisor

- Access:

- View dashboards, reports, machines

- Categorize downtime

- Reject parts

- Cannot create/delete reports

- Cannot manage users

- Use Case: Shift supervisors, floor leads

3. Manager

- Access:

- All Supervisor capabilities

- Create/save/delete reports

- Manage users (invite, edit, delete)

- Export data

- Use Case: Operations managers, plant managers

4. IT Admin

- Access:

- All Manager capabilities

- Configure SSO

- Manage Edge Devices

- Configure API keys

- System-level settings

- Use Case: IT department personnel

5. Executive

- Access: Full access to all settings and features

- Use Case: Plant managers, VPs, executives

Inviting Users

Step-by-Step:

- Navigate to Settings → Users

- Click "Invite Users" button

- Enter email addresses:

- One email per line

- Can invite multiple users at once

- Select Role from dropdown (applies to all invited users in this batch)

- Click "Send Invitations"

Example:

john.doe@company.com

jane.smith@company.com

bob.jones@company.com

Role: Supervisor

What Happens:

- Each user receives invitation email

- They click link to create password

- Account activated with assigned role

Editing Users

Changing User Role:

- Navigate to Settings → Users

- Find user in list

- Click Edit (pencil icon)

- Change Role dropdown

- Click Save

Deactivating Users:

- Click Deactivate to disable account (user cannot log in)

- Account retained for historical data

- Can be reactivated later

Deleting Users:

- Click Delete to permanently remove account

- Historical data (downtime categorizations, etc.) retained but unlinked from user

User List

Columns:

- Name: User's name (from email or profile)

- Email: User's email address

- Role: Current role

- Status: Active or Inactive

- Last Login: When user last logged in

Filtering:

- Search by name or email

- Filter by role

- Filter by status (Active/Inactive)

[Recommended Image]: Screenshot of Users list with roles visible

Machine Groups

What are Machine Groups?

Machine Groups organize machines into logical categories for filtering, reporting, and downtime categorization.

Access: Settings → Machine Groups

Who Can Manage: Managers, Executives, IT Admins

Purpose of Machine Groups

Use Cases:

- Filtering: View specific group on dashboards (e.g., "CNC Mills" only)

- Reporting: Run reports for specific group

- Downtime Categorization: Assign different downtime categories to different groups

- ERP Integration: Map groups to ERP work centers

Example Groups:

- CNC Mills

- CNC Lathes

- Manual Welding

- Grinders

- CMMs (Coordinate Measuring Machines)

Creating Machine Groups

Step-by-Step:

- Navigate to Settings → Machine Groups

- Click "Add Group" button

- Enter Group Name (e.g., "CNC Mills")

- (Optional) Select Downtimes: Choose which downtime categories apply to this group

- (Optional) Enter ERP ID: If integrating with ERP, enter work center ID

- Click "Save"

Downtime Category Assignment: Important: Different groups can have different downtime categories.

Example:

Group: CNC Mills

Downtimes: Tool Change, Setup, Material Unavailable, Maintenance

Group: Manual Welding

Downtimes: Waiting for Welder, Material Unavailable, Electrode Change

Why This Matters: Operators on tablets only see downtime categories relevant to their machine group, reducing clutter and improving categorization accuracy.

Assigning Machines to Groups

Method 1: During Machine Creation

- When adding machine, select group from dropdown

Method 2: Edit Existing Machine

- Navigate to Assets → Machines → Select Machine

- Click "Edit"

- Change "Machine Group" field

- Click "Save"

Method 3: Bulk Assignment

- Use CSV import to assign many machines to groups at once

ERP Integration

ERP ID Field:

- Maps MachineMetrics group to ERP work center or resource group

- Used for ERP integrations (IQMS, E2, JobBOSS, etc.)

- Format depends on ERP system

Example:

MachineMetrics Group: CNC Mills

ERP ID: WC-100

Managing Machine Groups

Editing Groups:

- Click group in list

- Modify name, downtimes, or ERP ID

- Click "Save"

Deleting Groups:

- Click "Delete"

- Machines in group are unassigned (not deleted)

- Reassign machines to different group before deleting

[Recommended Image]: Screenshot of Machine Groups list and creation form

Machine Schedules

What are Machine Schedules?

Machine Schedules define shifts for calculating scheduled time and OEE Availability.

Access: Settings → Machine Schedules

Who Can Manage: Managers, Executives, IT Admins

Purpose of Schedules

Why Define Schedules:

- Calculate Scheduled Time for OEE Availability

- Determine when machines are expected to run

- Separate attended vs. unattended shifts

- Enable shift-based reporting

Impact on OEE:

Availability = (Running Time / Scheduled Time) × 100%

Scheduled time is the denominator. Without shifts defined, scheduled time = 24/7.

Creating Shifts

Step-by-Step:

- Navigate to Settings → Machine Schedules

- Click "Add Shift"

- Configure shift:

- Shift Name: Descriptive name (e.g., "First Shift", "Day Shift")

- Start Time: When shift begins (e.g., 6:00 AM)

- End Time: When shift ends (e.g., 2:00 PM)

- Days: Which days shift runs (Monday - Sunday)

- Shift Type: Attended or Unattended

- Machine Group: Apply to specific group or all machines

- Click "Save"

Example Shifts:

First Shift: 6:00 AM - 2:00 PM, Mon-Fri, Attended, CNC Mills

Second Shift: 2:00 PM - 10:00 PM, Mon-Fri, Attended, CNC Mills

Third Shift: 10:00 PM - 6:00 AM, Mon-Fri, Unattended, CNC Mills

Weekend Shift: 8:00 AM - 4:00 PM, Sat-Sun, Attended, CNC Mills

Attended vs. Unattended Shifts

Attended Shifts:

- All time during shift is scheduled

- Used for shifts with operators present

- Downtime during shift hurts Availability

Unattended Shifts:

- Only time when machine is active counts as scheduled

- Used for overnight or weekend shifts without operators

- Unattended Inactive Threshold (from Downtime settings) determines when machine is considered "unscheduled"

- If inactive > threshold: Time becomes unscheduled (doesn't hurt Availability)

- If active: Time becomes scheduled

Example:

Third Shift (Unattended): 10:00 PM - 6:00 AM

Unattended Inactive Threshold: 30 minutes

Scenario:

- Machine runs 10:00 PM - 2:00 AM (4 hours active) → Scheduled

- Machine idle 2:00 AM - 6:00 AM (4 hours idle > 30 min threshold) → Unscheduled

Scheduled Time: 4 hours (not 8 hours)

Non-Overlapping Shifts

Important Constraint: Shifts cannot overlap within the same machine group.

Allowed:

Group: CNC Mills

- First Shift: 6:00 AM - 2:00 PM

- Second Shift: 2:00 PM - 10:00 PM

- Third Shift: 10:00 PM - 6:00 AM

✅ No overlap

Group: CNC Lathes

- Day Shift: 9:00 AM - 5:00 PM

✅ Different group, can have different schedule

Not Allowed:

Group: CNC Mills

- First Shift: 6:00 AM - 2:00 PM

- Overlap Shift: 1:00 PM - 9:00 PM

❌ Overlap from 1:00 PM - 2:00 PM

Applying Schedules to Machines

Schedules are applied based on Machine Group:

- Create shift and assign to machine group

- All machines in that group inherit the shift schedule

Changing Machine Schedule:

- Move machine to different group (with different schedule)

- Or modify shift assigned to machine's group

Managing Schedules

Editing Shifts:

- Click shift in list

- Modify times, days, or type

- Click "Save"

Deleting Shifts:

- Click "Delete"

- Historical data recalculates based on new schedule configuration

Important: Changing schedules affects historical OEE calculations (data recalculates).

[Recommended Image]: Screenshot of Machine Schedules list and shift creation form

Activities

What are Activities?

Activities distinguish between Setup and Production modes during production runs.

Access: Settings → Activities

Who Can Manage: Managers, Executives, IT Admins

Activity Types

Two Activity Types:

1. Setup

- Machine is being prepared for production

- Includes: Loading fixtures, setting tools, running first article, adjustments

- Tracked separately from production time

2. Production

- Machine is actively producing parts

- Normal production cycle

Purpose of Activities

Why Track Activities:

- Separate Setup Time: Track how long setup takes vs. actual production

- OEE Impact: Planned setup can be excluded from Availability and Performance calculations

- Improvement Opportunities: Identify operations with excessive setup time

- Operator Workflow: Operators switch between Setup and Production on tablets

See Also: Operator Dashboard Guide

Configuration

Activities are generally pre-configured and require minimal setup.

Available Settings:

- Enable/disable activity tracking (toggle)

- Configure planned setup duration for operations

If Activity Tracking Disabled:

- All time considered "Production"

- No distinction between setup and production

- Operators don't select activity on tablets

Planned Setup

Configuring Expected Setup Time:

- Set at operation level (not in Activities menu)

- Navigate to Production → Operations → Select Operation → Edit

- Enter Expected Setup Time (minutes)

Impact:

- If setup time ≤ expected: Marked as planned (can be excluded from OEE)

- If setup time > expected: Excess marked as unplanned (affects OEE)

See Also: Production & Analytics Guide

[Recommended Image]: Screenshot of Activities settings

Auto Setup

What is Auto Setup?

Auto Setup automatically transitions machines from Setup to Production mode based on cycle consistency when using APM (Automatic Production Monitoring).

Access: Settings → Auto Setup

Who Can Manage: Managers, Executives, IT Admins

Prerequisites:

- Machine must use APM (Automatic Production Monitoring)

- APM typically used with machines reporting program headers via Ethernet (FOCAS, MTConnect, OPC-UA)

How Auto Setup Works

Automatic Workflow:

1. Job Change Detected (via APM)

- Machine program changes (new part number/operation detected)

- APM creates new Production Run

- Auto Setup activates: Machine automatically enters Setup mode

2. Consistent Parts Detected

- MachineMetrics monitors cycle times

- Once cycle times stabilize and become consistent

- Auto Setup deactivates: Machine automatically switches to Production mode

3. Next Job Change

- Process repeats for next operation

Example:

Time: 8:00 AM - Program changes to Part ABC-123

Action: Auto Setup puts machine in Setup mode

Time: 8:00 AM - 8:30 AM - Operator sets tools, runs first articles (cycle times variable)

Time: 8:30 AM - Cycle times stabilize at ~120 seconds

Action: Auto Setup switches machine to Production mode

Time: 8:30 AM - 2:00 PM - Production runs (cycle times consistent)

Time: 2:00 PM - Program changes to Part XYZ-789

Action: Auto Setup puts machine back in Setup mode

Benefits

- No Operator Input Required: Automatic tracking of setup vs. production

- Accurate Setup Time: Based on actual cycle consistency, not manual operator selection

- Reduced Operator Burden: One less thing for operators to remember

Enabling Auto Setup

Step-by-Step:

- Navigate to Settings → Auto Setup

- Select machines to enable Auto Setup (must have APM enabled)

- Toggle Enable Auto Setup for each machine

- Click "Save"

Bulk Enable:

- Select multiple machines

- Click "Enable All"

Limitations

Auto Setup Requires:

- APM (Automatic Production Monitoring) enabled

- Machine with consistent cycle times

- Program header data from machine

Not Compatible With:

- Manual operation start/stop (non-APM machines)

- Highly variable cycle times

- One-off jobs or prototype runs

See Also: Production & Analytics Guide

[Recommended Image]: Screenshot of Auto Setup configuration with machines listed

Downtimes

What is Downtimes?

Downtimes is where you configure downtime categories (reasons) and general downtime settings.

Access: Settings → Downtimes

Who Can Manage: Managers, Executives, IT Admins

General Downtime Settings

Access: Settings → Downtimes → General

Key Settings:

1. Microstop Duration (seconds)

Purpose: Threshold separating microstops from long downtime.

Configuration:

- Enter duration in seconds (e.g., 60)

- Default: 60 seconds

Impact:

- Downtime < threshold: Categorized as "Microstop"

- Downtime ≥ threshold: Categorized as "Long Downtime"

Reporting:

- Microstops typically excluded from downtime reports

- Long downtime requires categorization

2. Downtime List Filter (seconds)

Purpose: Hide very short downtime events from operator categorization list.

Configuration:

- Enter duration in seconds (e.g., 30)

- Default: 30 seconds

Impact:

- Downtime < filter: Hidden from operator's categorization list on tablet

- Prevents operators from being prompted to categorize very short stops

Example:

Downtime List Filter: 30 seconds

5-second stop: Hidden (not prompted)

45-second stop: Shown (operator can categorize)

3. Unattended Inactive Threshold (minutes)

Purpose: For unattended shifts, determines when idle time becomes unscheduled.

Configuration:

- Enter duration in minutes (e.g., 30)

- Default: 30 minutes

Impact:

- During unattended shifts, if machine idle > threshold:

- Time becomes unscheduled (doesn't affect Availability)

- If machine idle < threshold:

- Time remains scheduled (affects Availability)

See Also: Machine Schedules and Understanding Your Data Guide

4. Exclude Planned Downtime from Production Metrics

Purpose: Exclude planned downtime (breaks, PM, etc.) from Availability and Performance calculations.

Configuration: Toggle on/off

Impact When Enabled:

- Planned downtime subtracted from scheduled time

- Does not hurt Availability or Performance

- Still included in Quality calculation

Impact When Disabled:

- All downtime (planned and unplanned) affects Availability equally

Example:

Scheduled Time: 8 hours (480 minutes)

Planned Break: 30 minutes

Planned Maintenance: 60 minutes

If Enabled:

Scheduled Time = 480 - 30 - 60 = 390 minutes

If Disabled:

Scheduled Time = 480 minutes (breaks/PM hurt Availability)

[Recommended Image]: Screenshot of General Downtime Settings

Downtime Categories

Access: Settings → Downtimes → Downtime Categories

Purpose: Define reasons for downtime that operators select on tablets.

See Also: Downtime & Quality Guide for comprehensive guide

Creating Downtime Categories

Step-by-Step:

- Navigate to Settings → Downtimes → Downtime Categories

- Click "Add Category"

- Enter Category Name

- Select Planned/Unplanned Behavior:

- Planned or Unplanned: Operator chooses

- Unplanned: Always unplanned

- Planned: Always planned

- Planned with Limit: Planned up to X minutes, then unplanned

- Select Color (for visual identification)

- Click "Save"

Creating Hierarchical Categories

Purpose: Nest categories for more specific root cause tracking.

Format: Use pipe (|) separator

Example:

Parent Category: Tooling

Child Category: Tooling | Tool Change

Grandchild Category: Tooling | Tool Change | End of Life

Steps:

- Create parent first:

Tooling - Create child:

Tooling | Tool Change(note the space before and after|) - Create grandchild:

Tooling | Tool Change | End of Life

Important: You must create each level separately.

In Settings, there is an example showing the correct format with the vertical space bar character (|).

Planned with Limit

Purpose: Mark downtime as planned up to a certain duration, then unplanned if it exceeds.

Example:

Category: Operator Break

Behavior: Planned with Limit

Limit: 15 minutes

Scenario:

Break duration: 10 minutes → Planned (OK)

Break duration: 20 minutes → 15 min planned, 5 min unplanned (excess)

Use Case: Allow reasonable breaks without affecting OEE, but flag excessive breaks.

Colors

Purpose: Visual identification on tablets, timelines, and reports.

Best Practice:

- Use consistent colors for related categories

- Example: All "Maintenance" categories = orange, all "Material" categories = blue

Operator View: Colors appear on:

- Operator Dashboard (tablet)

- Timeline visualization

- Downtime reports

Assigning Categories to Machine Groups

When creating/editing Machine Groups:

- Select which downtime categories apply to that group

- Only selected categories appear on tablets for machines in that group

Example:

Group: CNC Mills

Categories: Tool Change, Setup, Material Unavailable, Maintenance

Group: Manual Welding

Categories: Waiting for Welder, Material Unavailable, Electrode Change

Operators on CNC Mills only see the 4 categories relevant to mills.

[Recommended Image]: Screenshot of Downtime Categories list and creation form with hierarchy example

Quality

What is Quality?

Quality is where you configure reject reasons (why parts are rejected).

Access: Settings → Quality

Who Can Manage: Managers, Executives, IT Admins

Purpose of Reject Reasons

Why Define Reject Reasons:

- Track why parts are rejected

- Root cause analysis (Pareto charts)

- Identify quality improvement opportunities

- Calculate Quality component of OEE

See Also: Downtime & Quality Guide for comprehensive guide

For Auto Reject Rules: Reject reasons configured here are used in the Auto Reject Rules feature in Labs to automatically map machine reject data items to quality categories. See Labs Guide - Auto Reject Rules for configuration details.

Creating Reject Reasons

Step-by-Step:

- Navigate to Settings → Quality → Reject Reasons

- Click "Add Reason"

- Enter Reason Name

- Select Scrap/Non-Conforming Behavior:

- Scrap or Non-Conforming: Operator chooses

- Scrap: Always marked as scrap

- Non-Conforming: Always marked as non-conforming

- Select Color (for visual identification)

- Click "Save"

Creating Hierarchical Reject Reasons

Format: Same as downtime categories, use pipe (|) separator

Example:

Parent: Dimensional

Child: Dimensional | Out of Specification

Grandchild: Dimensional | Out of Specification | Groove | Diameter Big

Steps:

- Create parent:

Dimensional - Create child:

Dimensional | Out of Specification - Create grandchild:

Dimensional | Out of Specification | Groove - Create great-grandchild:

Dimensional | Out of Specification | Groove | Diameter Big

Operator View: On tablets, reject reasons appear nested for easy selection.

Scrap vs. Non-Conforming

Scrap:

- Part is unusable

- Cannot be reworked

- Total loss

Non-Conforming:

- Part is outside spec but may be reworked

- Or used with deviation approval

- Potential recovery

Configuration:

- Set behavior when creating reject reason

- Or let operator choose (Scrap or Non-Conforming)

Colors

Purpose: Visual identification in reports and dashboards.

Operator View: Colors appear on:

- Operator Dashboard (tablet)

- Quality reports

- OEE Quality component visualization

Best Practices

Specific Reject Reasons:

- Avoid generic "Quality Issues"

- Use hierarchy:

Dimensional | Out of Spec | Feature X | Too Large - Specific reasons enable targeted improvements

Example Hierarchy:

Dimensional

├─ Out of Specification

│ ├─ Groove

│ │ ├─ Diameter Big

│ │ └─ Diameter Small

│ └─ Drill

│ ├─ Hole Size Big

│ └─ Hole Size Small

└─ Surface Finish

├─ Rough Surface

└─ Scratches

Tooling Issues

├─ Dull Tool

├─ Tool Break

└─ Wrong Tool

[Recommended Image]: Screenshot of Reject Reasons list and creation form with hierarchy example

Operators

What is Operators?

Operators is where you add operator names for login on Operator Dashboard (tablets).

Access: Settings → Operators

Who Can Manage: Managers, Executives, IT Admins

Prerequisites:

- Operator Insight must be enabled in Company Settings

Purpose of Operators

Why Add Operators:

- Track individual operator performance

- Identify training needs

- Recognize top performers

- Enable operator-specific reporting

Important: Operator names are not MachineMetrics user accounts. They:

- Have no password

- Have no email

- Have no access to MachineMetrics web interface

- Only appear on tablet sign-in list

Adding Operators

Step-by-Step:

- Navigate to Settings → Operators

- Click "Add Operator"

- Enter Operator Name:

- Full name (e.g., "John Smith")

- Last name only (e.g., "Smith")

- Employee ID (e.g., "EMP-1234")

- Or nickname (e.g., "Johnny")

- Click "Save"

Important:

- Names must be unique

- Use consistent naming convention (e.g., always "FirstName LastName")

- Operator immediately appears on tablet sign-in list

Managing Operators

Editing Operators:

- Find operator in list

- Click Edit (pencil icon)

- Change name

- Click "Save"

Archiving Operators:

- Click Archive to remove from tablet sign-in list

- Historical data retained

- Can be unarchived later

Do Not Delete:

- Archiving is preferred over deleting

- Deleting removes operator but may break historical data links

Operator Runs

Correcting Operator Data: If operator forgot to log in or logged in incorrectly:

- Navigate to Production → Operator Runs

- Click "Add Operator Run" or "Edit" existing run

- Assign correct operator to time period

- Corrects historical data

See Also: Production & Analytics Guide

[Recommended Image]: Screenshot of Operators list and add operator form

Operator Dashboard

What is Operator Dashboard Settings?

Operator Dashboard settings control the behavior and appearance of tablets on the shop floor.

Access: Settings → Operator Dashboard

Who Can Manage: Managers, Executives, IT Admins

General Settings

Access: Settings → Operator Dashboard → General

Available Toggles:

1. Enable/Disable Machine Switching

Purpose: Allow operators to switch between machines on tablet.

Options:

- Enabled: Operators can select different machine from dropdown

- Disabled: Tablet locked to one machine

Use Case: Disable if tablets are dedicated to specific machines (prevents confusion).

2. Force Machine Downtime Categorization

Purpose: Require operators to categorize downtime before proceeding.

Options:

- Enabled: Pop-up blocks tablet until downtime categorized

- Disabled: Pop-up can be dismissed (categorize later)

Use Case: Enable to ensure all downtime is categorized. Disable if operators frequently busy and need flexibility.

3. Remove Rejects from Part Count

Purpose: Subtract rejected parts from total part count display.

Options:

- Enabled: Part count shows only good parts

- Disabled: Part count shows total parts (good + rejected)

Use Case: Enable if you only want to display good parts to operators.

4. Enable Work Order Fields

Purpose: Allow operators to enter work order numbers on tablets.

Options:

- Enabled: Operators can add/edit work orders

- Disabled: No work order functionality

Use Case: Enable if integrating with ERP or tracking work orders.

See Also: Operator Dashboard Guide

5. Enable Operator Auto Sign Out at End of Shift

Purpose: Automatically log operators out when shift ends.

Options:

- Enabled: Operators logged out at shift end time (based on schedule)

- Disabled: Operators must manually log out

Use Case: Enable to ensure clean shift transitions.

Auto Downtime Settings

Access: Settings → Operator Dashboard → General

Two Timing Settings:

1. Initial Prompt Delay

Purpose: How long after downtime begins before toast notification appears.

Configuration:

- Enter delay in seconds (e.g., 10)

- Default: 10 seconds

Impact:

- Downtime begins at 2:00 PM

- Toast appears at 2:00:10 PM (after 10-second delay)

Use Case: Short delay filters out very brief stops (machine stops, immediately resumes).

2. Categorization Prompt Delay

Purpose: How long before full categorization prompt replaces toast.

Configuration:

- Enter delay in seconds (e.g., 30)

- Default: 30 seconds

Impact:

- Downtime begins at 2:00 PM

- Toast appears at 2:00:10 PM

- Full prompt appears at 2:00:30 PM (if not categorized via toast)

Toast vs. Full Prompt:

- Toast: Small notification in bottom right (can dismiss)

- Full Prompt: Larger prompt (blocks tablet if "Force Categorization" enabled)

[Recommended Image]: Screenshot of Operator Dashboard General settings with all toggles visible

Manage Tabs

Access: Settings → Operator Dashboard → Manage Tabs

Purpose: Customize which tabs appear on Operator Dashboard tablets.

Default Tabs:

- Part Count

- Utilization

- All Downtime

- Active Alarms

- Parts Goal

- Current Cycle Time

- OEE

Managing Tabs:

Toggle Tabs On/Off:

- Navigate to Settings → Operator Dashboard → Manage Tabs

- Toggle each tab On or Off

- Click "Save"

Reorder Tabs:

- Drag and drop tabs to reorder

- Order on settings page = order on tablets

Adding Custom Tabs

Purpose: Embed external content (websites, documents, videos) on tablets.

Step-by-Step:

- Navigate to Settings → Operator Dashboard → Manage Tabs

- Click "Add Tab"

- Configure:

- Tab Name: Display name (e.g., "Work Instructions")

- URL: Full URL to content

- Icon (optional): Select icon for tab

- Click "Save"

Supported Content:

- Google Forms (checklists, surveys)

- Google Drive documents (PDFs, Docs)

- Websites (CNC calculators, reference tools)

- YouTube/Vimeo videos (embedded)

- Tool Life Monitoring Dashboard

- Any iframe-compatible content

Example: Adding Tool Life Monitoring Tab

One of the most popular custom tabs is the Tool Life Monitoring Dashboard, which allows operators to see tool life status directly on their tablet without leaving the Operator Dashboard.

Step-by-Step to Add Tool Life Tab:

- Navigate to Settings → Operator Dashboard → Manage Tabs

- Click "Add Tab"

- Enter the following:

- Tab Name:

Tool Life - URL: Your Tool Life dashboard URL (format:

https://app.machinemetrics.com/dashboards/[dashboard-id]) - Icon: Select the wrench or tool icon

- Tab Name:

- Click "Save"

How to Get Your Tool Life Dashboard URL:

- Go to Dashboards → Find your Tool Life dashboard

- Open the dashboard

- Copy the URL from your browser's address bar

- Use this URL when creating the custom tab

What Operators See:

Once configured, operators can tap the Tool Life tab on their tablet to see:

| Information | Description |

|---|---|

| Tool List | All tools for their machine |

| Life Remaining | Percentage or count remaining for each tool |

| Status Colors | Green (OK), Yellow (Warning), Red (Critical) |

| Time/Cycles Left | Estimated remaining usage |

Benefits for Operators:

- No navigation required — Tool life visible without leaving the Operator Dashboard

- Proactive tool changes — See when tools are approaching end of life

- Reduce scrap — Change tools before they fail and damage parts

- Stay informed — Quick glance during production without interruption

Tip: Position the Tool Life tab near the beginning of the tab order so operators can access it quickly.

Other Example Use Cases:

Custom Tab: "Setup Instructions"

URL: https://docs.google.com/document/d/abc123

Custom Tab: "Feeds & Speeds Calculator"

URL: https://www.cnccookbook.com/feeds-speeds-calculator/

Custom Tab: "Quality Checklist"

URL: https://docs.google.com/forms/d/xyz789

Limitations:

- Sites that block iframes won't work

- Authentication may be required (e.g., Google account login)

See Also: Operator Dashboard Guide, Dashboards Guide, and Tool Life Monitoring Guide

[Recommended Image]: Screenshot of Manage Tabs interface with custom tab creation form

API Keys

What are API Keys?

API Keys allow external systems to access MachineMetrics data programmatically.

Access: Settings → API Keys

Who Can Manage: IT Admins, Executives

Use Cases:

- ERP integration (pull production data)

- Custom dashboards (external BI tools)

- Data warehouse sync

- Third-party applications

API Scopes

Purpose: Control what data the API key can access (principle of least privilege).

Available Scopes:

1. User

- Access: Full control of user profile

- Use Case: User management integrations

2. ERP Read

- Access: Read ERP integration data

- Use Case: View ERP-synced information

3. ERP Write

- Access: Write access for ERP integration

- Use Case: Create/update operations, work orders from ERP

4. Reporting Read

- Access: Read access for reportable data

- Use Case: Pull production reports, OEE data, downtime data

- Recommended: Most common scope for data export

5. Machine Read

- Access: Read machine information

- Use Case: Get machine list, status, configuration

6. Machine Write

- Access: Write access for machines

- Use Case: Create/update machines programmatically

7. Annotation (Downtime)

- Access: Read/write access for downtime categorizations

- Use Case: Auto-categorize downtime via external rules engine

8. Annotation Read

- Access: Read-only access for annotations

- Use Case: View downtime categorizations

9. Part Adjustment

- Access: Write access for part adjustments

- Use Case: Correct part counts programmatically

10. Gateway Read

- Access: Read machine information and support data

- Use Case: Edge Device diagnostics

11. Ingest Activity

- Access: Allow access to activities data

- Use Case: Ingest activity data from external systems

12. Operator

- Access: Write access for operators

- Use Case: Sync operator list from HR system

13. System Gateway

- Access: Manage Edge Devices

- Use Case: Configure Edge Devices programmatically

14. System Gateway Read

- Access: List available Edge Devices and status

- Use Case: Monitor Edge Device health

Creating API Keys

Step-by-Step:

- Navigate to Settings → API Keys

- Click "Add Key"

- Enter Key Name (descriptive, e.g., "ERP Integration - Read Only")

- Select Scope(s):

- Recommendation: Only select what you need

- Example: For reporting, select only "Reporting Read"

- Click "Save"

- API Key displayed (long alphanumeric string)

- IMPORTANT: Copy and store key safely (cannot be retrieved later)

- Click "Close"

Security Best Practice:

- Select minimum required scopes

- Create separate keys for different integrations

- Name keys descriptively

Example:

Key Name: "Power BI Dashboard - Reporting Read Only"

Scopes: Reporting Read

Use: Pull OEE and production data for Power BI dashboards

Managing API Keys

Viewing Keys:

- List shows:

- Key name

- Scopes assigned

- Created date

- Last used date

Revoking Keys:

- Find key in list

- Click "Revoke" or "Delete"

- Confirm revocation

- Key immediately invalid

Use Case for Revocation:

- Employee leaves (revoke their personal API key)

- Integration no longer used

- Security concern (key may be compromised)

Using API Keys

Authentication: Include API key in HTTP request header:

Authorization: Bearer YOUR_API_KEY_HERE

Example API Call (cURL):

curl -X GET "https://api.machinemetrics.com/v1/machines" \

-H "Authorization: Bearer abc123def456..."

See MachineMetrics API Documentation:

- Full API documentation available at developer portal

- Endpoints for machines, production, downtime, quality, etc.

[Recommended Image]: Screenshot of API Keys list and scope selection during creation

Integrations

What is Integrations?

Integrations is where you configure connections to external systems like ERP, MES, CMMS, and other platforms.

Access: Settings → Integrations

Who Can Manage: IT Admins, Executives

Supported Integrations

Common Integrations:

- MaintainX: CMMS (Computerized Maintenance Management System)

- ERP Systems: IQMS, E2, JobBOSS, SAP, etc.

- MES Systems: Factory MES, etc.

- Custom Integrations: Via webhooks or API

Configuring Integrations

General Process:

- Navigate to Settings → Integrations

- Find integration to configure

- Click "Configure" or "Connect"

- Follow integration-specific setup:

- Enter credentials (API keys, usernames, passwords)

- Configure sync settings (what data to sync, how often)

- Map fields (MachineMetrics fields → ERP fields)

- Click "Save" or "Connect"

- Test connection

Integration-Specific Setup: Each integration has unique configuration requirements. Consult integration-specific documentation or contact support.

MaintainX Integration (Example)

Purpose: Sync work orders between MachineMetrics and MaintainX CMMS.

Configuration:

- Navigate to Settings → Integrations → MaintainX

- Enter MaintainX API Key

- Configure sync settings:

- Create work orders in MaintainX for specific alarm codes

- Sync work order status back to MachineMetrics

- Click "Save"

Use Case: Alarm occurs → Workflow creates MaintainX work order → Maintenance receives notification → Completes work in MaintainX → Status syncs back to MachineMetrics.

Webhooks (Custom Integrations)

If your system isn't listed:

- Use webhooks (configured in Workflows)

- Or use API keys to build custom integration

See Also: Automations & Workflows Guide

[Recommended Image]: Screenshot of Integrations page with available integrations listed

Single Sign-On

What is Single Sign-On (SSO)?

Single Sign-On (SSO) allows users to log into MachineMetrics using their company's existing authentication system (Azure AD, Okta, Google Workspace, etc.).

Access: Settings → Single Sign-On

Who Can Manage: IT Admins, Executives

Prerequisites:

- SSO provider (Azure AD, Okta, Google Workspace, OneLogin, etc.)

- IT Admin or Executive role in MachineMetrics

Benefits of SSO

Why Enable SSO:

- Single Credentials: Users use same username/password for all company apps

- Centralized Management: IT manages users in one place (SSO provider)

- Security: Enforce company password policies, MFA, etc.

- Automatic Provisioning: Users added to SSO provider automatically get MachineMetrics access

SSO Configuration Requirements

Information Needed from SSO Provider:

1. SSO Provider Name

- Name of your SSO provider (e.g., "Azure AD", "Okta", "Google Workspace")

2. Client ID

- Unique identifier for MachineMetrics app in SSO provider

- Example:

abc123-def456-ghi789

3. Client Secret

- Secret key for authentication

- Example:

xyz789-abc123-mno456 - Important: Keep secret secure (like API keys)

4. Issuer URL

- Base URL of SSO provider

- Example (Azure AD):

https://login.microsoftonline.com/[tenant-id]/v2.0 - Example (Okta):

https://yourcompany.okta.com

Configuring SSO

Step-by-Step:

- Navigate to Settings → Single Sign-On

- Click "Configure SSO"

- Enter configuration:

- SSO Provider Name: (e.g., "Azure AD")

- Client ID: From SSO provider

- Client Secret: From SSO provider

- Issuer URL: From SSO provider

- Click "Save"

- Click "Test SSO" to verify configuration

- If successful: SSO enabled for your company

After Enabling SSO:

- Login page shows "Sign in with [Provider]" button

- Users click button → Redirected to SSO provider → Authenticate → Redirected back to MachineMetrics

SSO Provider Setup

Each SSO provider requires app registration:

General Steps (Provider-Specific):

- Log into SSO provider admin console

- Create new application (MachineMetrics)

- Configure redirect URLs (provided by MachineMetrics support)

- Copy Client ID and Client Secret

- Enter in MachineMetrics SSO settings

Consult MachineMetrics Support:

- SSO setup is complex and provider-specific

- Contact support@machinemetrics.com for detailed setup guide

- Support can provide redirect URLs and assist with configuration

Managing SSO

Testing SSO:

- Click "Test SSO" button to verify configuration

- Opens new window with SSO login flow

- If successful: Configuration correct

Disabling SSO:

- Click "Disable SSO" to revert to standard login

- Users return to username/password login

Editing SSO Configuration:

- Click "Edit"

- Update Client ID, Client Secret, or Issuer URL

- Click "Save"

- Test again

Troubleshooting SSO

Common Issues:

"SSO login fails"

- Verify Client ID and Client Secret correct

- Check Issuer URL (correct tenant ID or domain?)

- Ensure redirect URLs configured in SSO provider

- Contact support for assistance

"Users not provisioning automatically"

- Check SCIM settings (if using automatic provisioning)

- Verify user roles mapped correctly

- May require additional SSO provider configuration

[Recommended Image]: Screenshot of SSO configuration form with fields labeled

Edge Management

What is Edge Management?

Edge Management provides centralized monitoring and administration of all edge devices in your MachineMetrics deployment. Edge devices are the on-premise gateways that connect machines to the MachineMetrics Cloud.

Access: Settings → Edge Management (or navigate to the Edge Management page from the main menu)

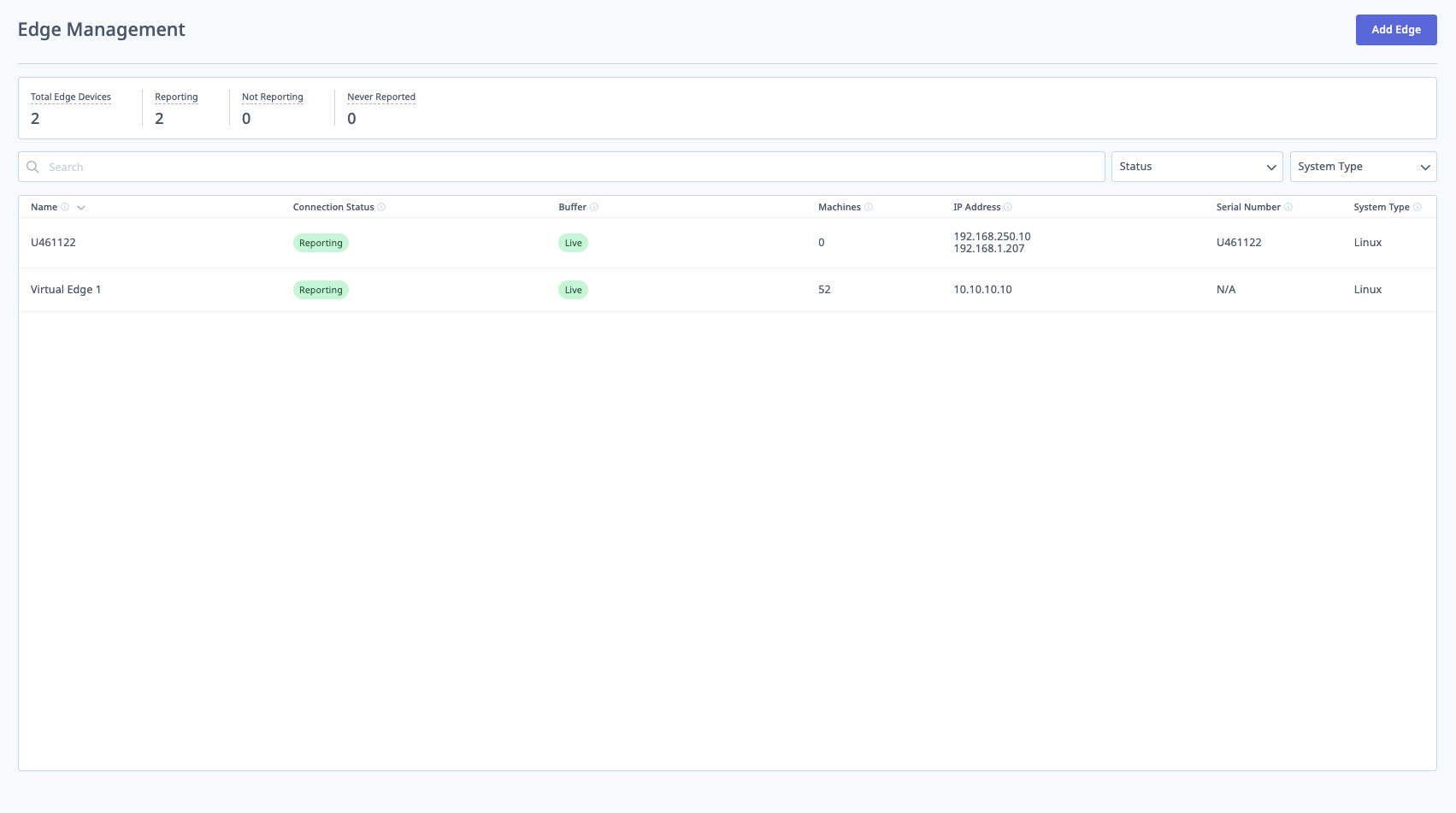

The Edge Management page displays all edge devices with their key metrics: connection status (green "Reporting" indicator), buffer status (showing data queue health), number of machines connected to each edge, IP addresses, serial numbers, and system type (Linux). The summary at the top shows total edge devices (2), reporting status (2), not reporting (0), and never reported (0). This centralized view allows administrators to monitor edge device health and connectivity across the entire deployment.

Key Metrics Displayed

Connection Status:

- Reporting (Green): Edge is actively connected and sending data

- Not Reporting (Red): Edge has stopped reporting (connectivity issue)

- Never Reported (Gray): Edge has been added but never connected

Buffer:

- Live: Data is flowing normally, no backlog

- Number (e.g., 52): Number of data points queued (indicates network or processing delay)

- High buffer numbers may indicate connectivity issues or high data volume

Machines:

- Total number of machines configured on each edge device

- Click the number to see which machines are connected to that edge

IP Address:

- Network IP address(es) of the edge device

- Multiple IPs indicate multiple network interfaces (machine network + internet)

Serial Number:

- Unique identifier for physical edge devices

- Virtual edges may show "N/A"

System Type:

- Operating system running on the edge (typically Linux)

Edge Management Actions

Adding New Edge Devices:

- Click Add Edge button (top right)

- Follow the edge device setup wizard

- See Edge Device Setup Guide for detailed instructions

Viewing Edge Details:

- Click on edge device name

- View detailed metrics:

- Connection history

- Machine assignments

- Network configuration

- Version information

- Health status

Troubleshooting Edge Issues:

If an edge shows Not Reporting:

- Check physical connectivity (cables, power)

- Verify network access (internet connection)

- Check firewall rules (see Network Requirements)

- Review edge device logs in detailed view

If Buffer is high:

- Check internet bandwidth

- Verify no network throttling

- Check if data collection rate is too high

- Contact support if buffer doesn't clear

Best Practices

Naming Edge Devices:

- Use descriptive names indicating location or purpose

- Examples: "Shop-Floor-Building-A", "Virtual-Edge-1", "Mill-Department-Edge"

Monitoring:

- Regularly check Edge Management page for connectivity issues

- Set up alerts for edge device failures (via Automations & Workflows)

Network Configuration:

- Ensure edge has reliable internet connection

- Use wired Ethernet (not WiFi) for production environments

- Assign static or reserved DHCP IP addresses

Capacity Planning:

- Physical edges can typically handle 50-100 machines

- Virtual edges depend on host resources

- Monitor buffer levels to identify capacity issues

Best Practices

User Management

1. Assign Appropriate Roles

- Don't give everyone Executive role

- Use Supervisor for floor leads, Manager for operations managers

- Reserve IT Admin for IT department only

2. Review User List Regularly

- Deactivate accounts for departed employees

- Audit roles quarterly (do users still need access?)

3. Use SSO if Available

- Centralized management

- Better security (company password policies, MFA)

Machine Organization

1. Create Logical Machine Groups

- Group by type (CNC Mills, CNC Lathes, Manual Welding)

- Or by location (Building A, Building B)

- Or by product line (Aerospace, Automotive)

2. Assign Appropriate Downtime Categories to Groups

- CNC machines: Tool Change, Setup, Material Unavailable

- Manual machines: Operator Unavailable, Manual Operations

- Don't show irrelevant categories (reduces clutter on tablets)

3. Name Machines Consistently

- Use format: "[Type]-[Number]" (e.g., "Mill-003", "Lathe-CNC-104")

- Or: "[Brand]-[Model]-[Number]" (e.g., "Haas-VF3-001")

- Avoid generic names ("Machine 1")

Schedules and Shifts

1. Define Shifts Before Going Live

- OEE calculations depend on scheduled time

- Without shifts, scheduled time = 24/7 (unrealistic)

2. Use Attended vs. Unattended Appropriately

- Attended: Shifts with operators present

- Unattended: Overtime or weekend shifts without operators

3. Review Shifts When Schedules Change

- Update shifts if company changes shift times

- Affects OEE calculations (historical data recalculates)

Downtime and Quality

1. Create Clear, Specific Categories

- "Tool Change" (clear) vs. "Tooling" (vague)

- Use hierarchy for specificity: "Tooling | Tool Change | End of Life"

2. Limit Number of Categories

- Too many categories = confused operators

- Aim for 10-20 top-level categories, with subcategories as needed

3. Train Operators on Categorization

- Show operators why it matters (improvements result from their data)

- Demonstrate on tablets during onboarding

API Keys and Integrations

1. Use Minimum Required Scopes

- Only select scopes you need

- Reduces security risk if key compromised

2. Name Keys Descriptively

- Include purpose and scope in name

- Example: "Power BI - Reporting Read Only"

3. Store Keys Securely

- Use password manager or secrets management system

- Don't hardcode in scripts or commit to version control

4. Rotate Keys Periodically

- Create new key, update integrations, revoke old key

- Recommended: Annually or after employee departure

Operator Dashboard

1. Start with Default Tabs, Customize Later

- Learn what operators actually use

- Remove unused tabs after observing usage

2. Test Custom Tabs Before Rolling Out

- Verify content loads on tablets

- Check mobile responsiveness (some sites don't work well on tablets)

3. Place Tablets Strategically

- Easily accessible without interrupting workflow

- Protected from chips, coolant, debris

Getting Help

Common Questions

"I'm not receiving workflow notifications"

- Check Profile settings → Notification preferences (default is "Never")

- Verify mobile number entered (if using text notifications)

- Check notification schedule (are you outside configured hours?)

"Operators don't see downtime categories on tablets"

- Check Machine Groups → Verify downtime categories assigned to machine's group

- Check Downtimes → Verify categories not archived

"OEE seems wrong / Availability too low"

- Check Machine Schedules → Verify shifts configured (without shifts, scheduled time = 24/7)

- Check Downtimes → General Settings → "Exclude planned downtime from production metrics" setting

- See Understanding Your Data Guide

"API key not working"

- Verify correct scope selected when creating key

- Check API key copied correctly (no extra spaces or characters)

- Ensure key not revoked

- Test with simple API call (e.g., list machines)

"SSO login fails"

- Verify Client ID and Client Secret correct

- Check Issuer URL (correct format for your SSO provider?)

- Contact MachineMetrics support for SSO troubleshooting

"Auto Setup not activating"

- Verify APM enabled for machine

- Check machine reporting program headers

- Ensure consistent cycle times (highly variable cycles won't trigger transition to Production)

Before Contacting Support

Gather Information:

- Which setting you're configuring (screenshot helpful)

- What you expected vs. what happened

- User role (do you have permission to edit this setting?)

- Steps to reproduce issue

Try These Steps:

- Refresh page (F5 or Cmd+R)

- Clear browser cache

- Try different browser (Chrome recommended)

- Verify permissions (IT Admin, Manager, or Executive role for most settings)

- Check system status (status.machinemetrics.com)

Contact Support

MachineMetrics Support:

- Email: support@machinemetrics.com

- Include:

- Setting you're trying to configure

- Screenshot of issue or error message

- Your role in MachineMetrics

- Expected behavior vs. actual behavior

For Training:

- Request system settings training session

- Ask about best practices for your industry or use case

- Schedule administrator onboarding for new team members

For SSO Setup:

- SSO setup is complex and provider-specific

- Contact support for detailed setup guide specific to your SSO provider

- Support can provide redirect URLs and configuration assistance

Next Steps:

- Configure your profile: Profile Settings

- Set up users and roles: Users Management

- Organize machines: Machine Groups and Machine Schedules

- Configure downtime and quality: Downtimes and Quality

- Set up integrations: API Keys, Integrations, Single Sign-On

Questions? Contact support@machinemetrics.com