Haas Connectivity Guide

- Overview

- Determining Your Haas Control Type

- Method 1: MTConnect (Next Generation Controls)

- Method 2: Haas Serial (Classic Controls)

- Macro and System Variables

- Using Both MTConnect and Serial Together

- Troubleshooting

- Additional Resources

Overview

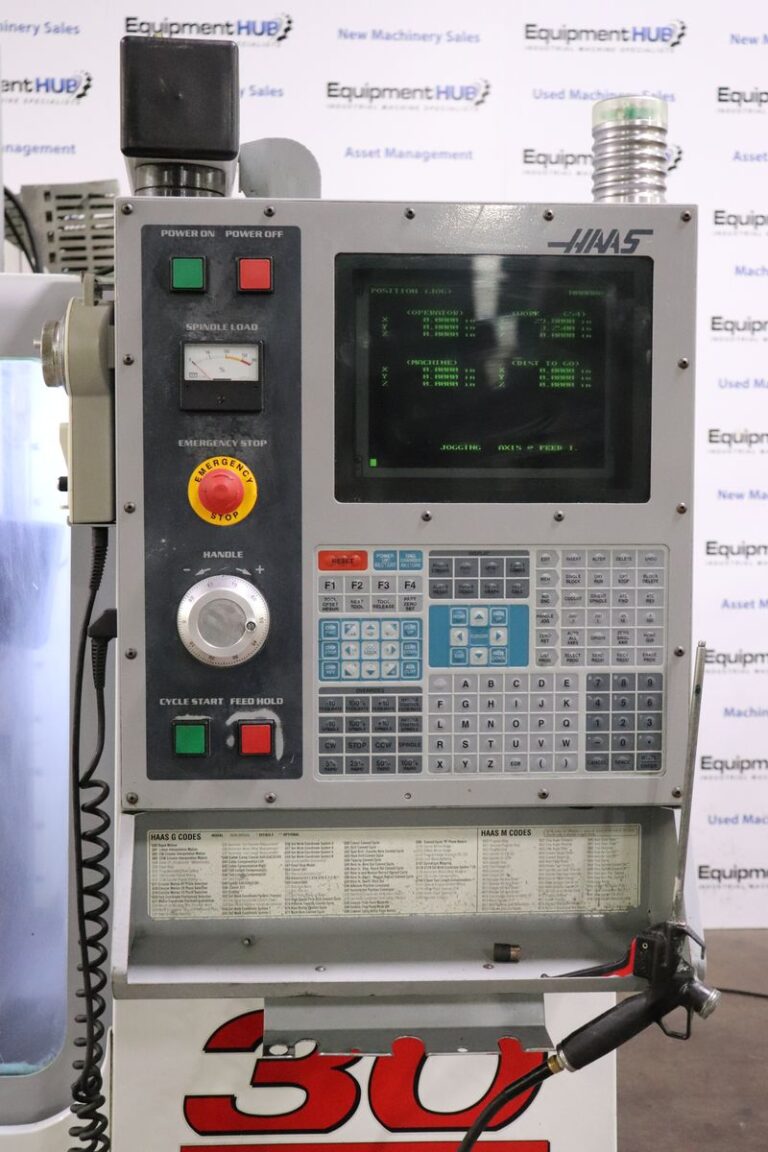

Haas CNC control panel. Haas machines connect via MTConnect (Next Generation controls) or Haas Serial/DPRNT (Classic controls), providing real-time production data and machine status.

MachineMetrics connects to Haas machines using two primary methods depending on your control type:

| Control Type | Connectivity Method | Port | Hardware Required |

|---|---|---|---|

| Next Generation (2017+) | MTConnect | 8082 | Ethernet only |

| Next Generation (2017+) | Haas Serial (MDC) | 4001 | Ethernet only |

| Classic Control (pre-2017) | Haas Serial (MDC) | 4001 | Moxa serial-to-Ethernet converter |

| Very Old (pre-2001) | Digital I/O | N/A | LabJack I/O module, sensors, wiring |

Recommended Approach:

- Next Gen Controls: Use MTConnect (primary) + Haas Serial (secondary) for macro variables

- Classic Controls: Use Haas Serial with Moxa converter

- Pre-2001 Machines: Use Digital I/O (no Setting 143 available)

Determining Your Haas Control Type

Use these methods to identify which type of Haas control you have:

Visual Identification

Next Generation Control (2017+):

Haas Next Generation control with modern touchscreen interface. Features graphical menus, network settings, and MTConnect capability.

Classic Control (pre-2017) with MDC:

Haas Classic control with text-based interface. Uses Haas Serial (MDC) over RS-232 with Moxa converter.

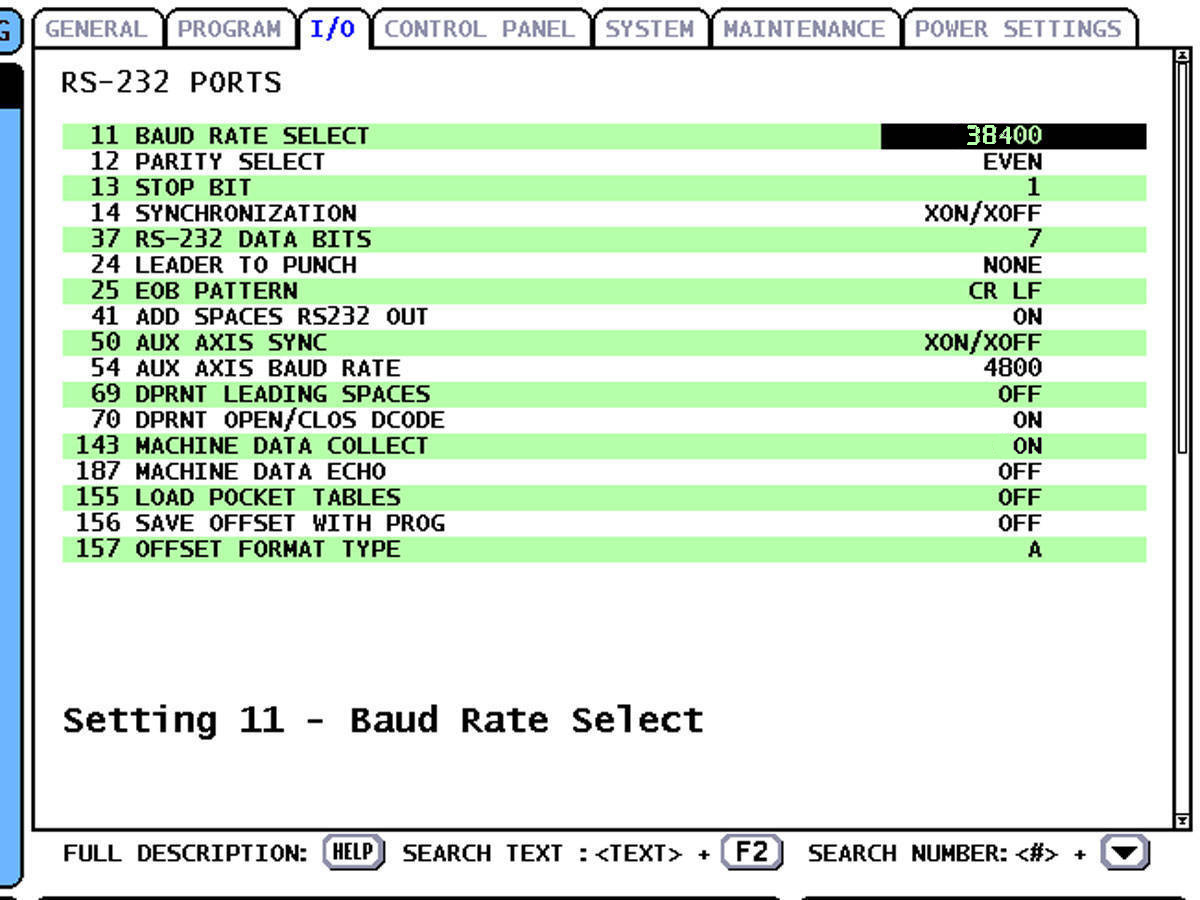

Classic Control (showing I/O Settings):

Haas Classic control showing Setting 143 (MACHINE DATA COLLECT) as ON/OFF toggle, indicating Classic control series.

Quick Identification Methods

Method 1: Visual Inspection

- Modern touchscreen with graphical interface = Next Generation Control (2017+)

- Text-based green/blue screen = Classic Control (pre-2017)

- Large touch display with icons = Next Generation Control

Method 2: Check Operator's Manual

- Cover states "Next Generation Control" → Use MTConnect

- No "Next Generation" label → Likely Classic control

Method 3: Check Network Settings

- Press SETTINGS button

- Navigate to NETWORK → WIRED CONNECTION

- Modern network interface with Ethernet settings = Next Gen

- No network section or basic interface = Classic

Method 4: Check Setting 143 (MACHINE DATA COLLECT)

- Press SETTINGS button

- Navigate to I/O or MISCELLANEOUS page

- Find Setting 143 - MACHINE DATA COLLECT

- Numerical value (e.g., 4001): Next Gen Control → Can use MTConnect or Ethernet Serial

- ON/OFF toggle: Classic Control → Use RS-232 Serial with Moxa converter

- Not present: Very old machine → Use Digital I/O instead

Method 1: MTConnect (Next Generation Controls)

Best option for Next Gen Haas machines. Provides comprehensive data with no additional hardware.

Prerequisites

- Haas machine with Next Generation control (2017+)

- Ethernet connection capability

- Network access between machine and Edge device

- MTConnect enabled on machine (usually enabled by default)

Configure Haas Next Gen Control

Step 1: Enable MTConnect

-

Press SETTINGS button

-

Navigate to NETWORK → WIRED CONNECTION

-

Configure network settings:

- IP Address: Set static IP or note DHCP address

- Subnet Mask: Match your network (typically 255.255.255.0)

- Gateway: Your network gateway

-

Navigate to NETWORK → MTCONNECT

-

Verify settings:

- MTConnect: ON

- Port: 8082 (default)

- Adapter: AGENT (default)

Step 2: Test MTConnect Connection

From a computer on the same network, open a web browser:

http://[MACHINE-IP]:8082/current

Replace [MACHINE-IP] with your machine's IP address.

Expected Response: You should see XML data showing machine information and data items.

Add MTConnect Adapter in MachineMetrics

-

Log into MachineMetrics

-

Go to Assets → Machines

-

Click Add Machine

-

Enter machine details:

- Machine Name: (e.g., "Haas VF-2")

- Make: Haas

- Model: (e.g., "VF-2")

- Edge Device: Select your Edge

-

Click Next

-

Select adapter type: MTConnect Agent

-

Enter connection details:

- Connection address:

[IP-ADDRESS]:[PORT](e.g.,10.26.5.142:8082)- Format is IP address followed by colon and port number

- Port 8082 is the standard MTConnect port for Haas Next Gen

- Adapter IP/Port: Will auto-populate (e.g.,

supervisor:8022) - Adapter version: Will auto-populate after connection

- Connection address:

-

Click Test Connection

-

If successful, click Save

Example:

- Connection address:

192.168.1.100:8082 - This connects to machine at IP 192.168.1.100 on MTConnect port 8082

Available MTConnect Data Items

Next Gen Haas machines provide via MTConnect:

- Execution State (execution) - ACTIVE, READY, INTERRUPTED, etc.

- Controller Mode (mode) - AUTO, MANUAL, MDI, JOG, etc.

- Program Name (program)

- Tool Number (tool)

- Spindle Speed (Sspeed)

- Spindle Load (Sload)

- Axis Positions (Xabs, Yabs, Zabs, etc.)

- Feed Rate (Fovr, path_feedrate)

- Part Count (PartCountAct)

- Alarms (message)

- And many more...

Method 2: Haas Serial (Classic Controls)

Haas Serial uses the MDC (Machine Data Collection) protocol, also known as DPRNT, to communicate with Haas machines.

When to Use Haas Serial

Classic Controls (pre-2017):

- This is your PRIMARY and ONLY connection method

- Classic controls do not have MTConnect

- Uses RS-232 serial port with Moxa serial-to-Ethernet converter

- Provides execution state, program data, and system variables

Next Gen Controls (2017+):

- Use MTConnect as your PRIMARY connection (see Method 1)

- Only add Haas Serial as SECONDARY if you need specific macro/system variables not available via MTConnect

- Next Gen Haas Serial uses Ethernet directly (no Moxa needed)

- Most customers only need MTConnect for Next Gen machines

⚠️ Important: If you have a Next Gen control, start with MTConnect (Method 1). Only add Haas Serial if MTConnect doesn't provide the specific data you need.

Two Physical Connection Types

| Connection Type | Control Type | Primary or Secondary | Physical Hardware | Port |

|---|---|---|---|---|

| RS-232 (via Moxa) | Classic (pre-2017) | Primary - your only option | RS-232 serial cable + Moxa NPort 5110 converter | 4001 (on Moxa) |

| Ethernet Direct | Next Gen (2017+) | Secondary - only for macro/system variables | Ethernet cable only | 4001 |

Both use the same Haas MDC protocol, just different physical connections.

Option A: Classic Controls - Haas Serial via RS-232 (Primary Connection)

For Classic Haas controls (pre-2017) - This is your primary and only connection method.

Prerequisites

- Haas machine with Classic control (pre-2017)

- Setting 143 available (ON/OFF type)

- RS-232 serial port on machine (typically DB-9 connector on control panel)

- Moxa NPort 5110 serial-to-Ethernet converter (provided by MachineMetrics)

- Serial cable (DB-9 female to DB-9 male)

- Network access between Moxa and Edge device

Configure Haas Classic Control

Step 1: Set RS-232 Parameters

- Press SETTINGS button

- Navigate to I/O page

- Configure RS-232 settings:

- Baud Rate: 38400

- Parity: EVEN

- Stop Bits: 1

- Data Bits: 7

Example of Haas I/O settings page showing RS-232 configuration and Setting 143

Example of Haas I/O settings page showing RS-232 configuration and Setting 143

Step 2: Enable Machine Data Collect

- Navigate to I/O or MISCELLANEOUS page

- Find Setting 143 - MACHINE DATA COLLECT

- Set to ON

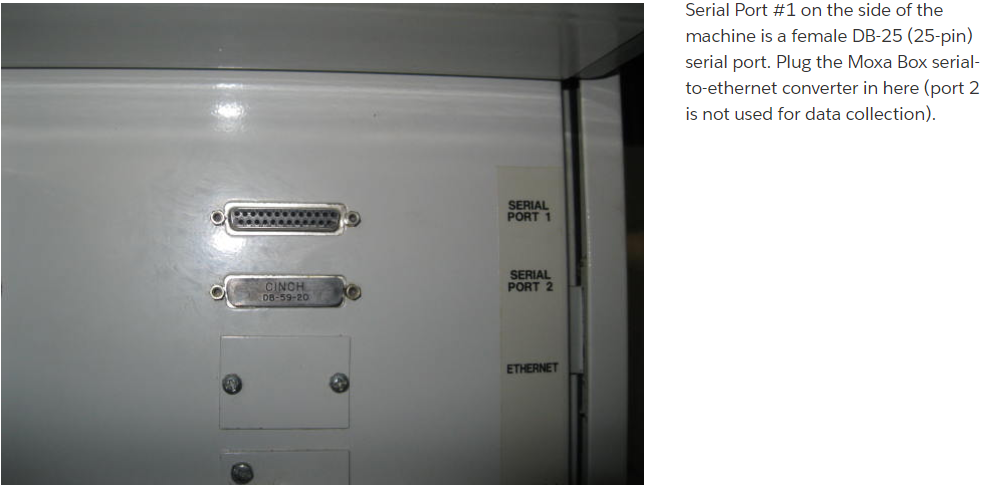

Step 3: Connect Hardware

- Connect DB-9 serial cable from machine's RS-232 port to Moxa converter

- Connect Ethernet cable from Moxa to your network switch

- Power on Moxa converter

- Note Moxa IP address (check label or use Moxa discovery tool)

Serial Port #1 on the side of the machine is a female DB-25 (25-pin) serial port. Plug the Moxa Box serial-to-ethernet converter in here (port 2 is not used for data collection).

Serial Port #1 on the side of the machine is a female DB-25 (25-pin) serial port. Plug the Moxa Box serial-to-ethernet converter in here (port 2 is not used for data collection).

Configure Moxa NPort Converter

-

Open web browser and navigate to Moxa IP address

-

Login (default: admin/admin or root/root)

-

Configure serial port (typically Port 1):

- Baud Rate: 38400

- Data Bits: 7

- Stop Bits: 1

- Parity: Even

- Flow Control: None

- Operation Mode: TCP Server

- TCP Port: 4001

-

Save settings and reboot Moxa

Add Haas Serial Adapter in MachineMetrics

-

Go to Assets → Machines

-

Click Add Machine

-

Select adapter type: Haas Serial

-

Enter connection details:

- Connection address:

[MOXA-IP]:[PORT](e.g.,10.26.5.200:4001)- Use Moxa converter IP address (not machine IP)

- Port 4001 is configured on the Moxa device

- Connection address:

-

Click Test Connection

-

If successful, click Save

Example:

- Connection address:

192.168.1.200:4001 - This connects to Moxa converter at IP 192.168.1.200 which is connected to the machine via RS-232

Option B: Next Gen Controls - Haas Serial via Ethernet (Secondary Connection Only)

For Next Gen machines (2017+) when you need macro/system variables not available via MTConnect.

⚠️ Important: This should only be used as a secondary adapter alongside MTConnect. MTConnect must be your primary connection for Next Gen controls.

When to Use This

Only add Haas Serial to a Next Gen machine if:

- You need specific macro variables (e.g., #3901, #3027, #13013)

- You need system variables not exposed by MTConnect

- MTConnect is already configured as your primary adapter

If you just need basic machine data, use MTConnect only.

Configure Haas Next Gen Control

- Press SETTINGS button

- Navigate to I/O or MISCELLANEOUS page

- Find Setting 143 - MACHINE DATA COLLECT

- Set value to 4001 (port number)

Add Haas Serial Adapter in MachineMetrics

-

Go to Assets → Machines

-

Select your existing Haas machine (with MTConnect already configured)

-

Click Add Secondary Adapter

-

Select adapter type: Haas Serial

-

Enter connection details:

- Connection address:

[IP-ADDRESS]:[PORT](e.g.,10.26.5.142:4001)- Use same machine IP as MTConnect

- Port 4001 is the Haas Serial/MDC port

- Connection address:

-

Click Test Connection

-

If successful, click Save

Example:

- Connection address:

192.168.1.100:4001 - This connects to machine at IP 192.168.1.100 on Haas Serial port 4001

- MTConnect on same machine uses port 8082

Macro and System Variables

Haas machines support reading macro and system variables via the Serial (DPRNT/MDC) connection. This is useful for accessing data not available via MTConnect, such as specific timers, counters, or custom machine settings.

Available Variable Types

Haas machines provide hundreds of macro and system variables. Below is a comprehensive reference of available system and macro variables that can be read from Haas NGC controllers.

Complete Haas System & Macro Variables Reference

| NGC Variable | Legacy Variable | Usage |

|---|---|---|

| #1-#33 | #1-#33 | Macro call arguments |

| #10000-#10149 | #100-#149 | General-purpose variables saved on power off |

| #10150-#10199 | #150-#199 | Probe values (if installed) |

| #10200-#10399 | N/A | General-purpose variables saved on power off |

| #10400-#10499 | N/A | General-purpose variables saved on power off |

| #10500-#10549 | #500-#549 | General-purpose variables saved on power off |

| #10550-#10599 | #550-#599 | Probe calibration data (if installed) |

| #10600-#10699 | #600-#699 | General-purpose variables saved on power off |

| #10700-#10799 | N/A | General-purpose variables saved on power off |

| #700-#749 | #700-#749 | Hidden variables for internal use only |

| #709 | #709 | Used for Fixture Clamp Input. Do not use for general purpose. |

| #10800-#10999 | #800-#999 | General-purpose variables saved on power off |

| #11000-#11063 | N/A | 64 discrete inputs (read only) |

| #1064-#1068 | #1064-#1068 | Maximum axis loads for X, Y, Z, A, and B axes |

| #1080-#1087 | #1080-#1087 | Raw analog to digital inputs (read only) |

| #1090-#1098 | #1090-#1098 | Filtered analog to digital inputs (read only) |

| #1098 | #1098 | Spindle load with Haas vector drive (read only) |

| #1264-#1268 | #1264-#1268 | Maximum axis loads for C, U, V, W, and T-axes |

| #1601-#1800 | #1601-#1800 | Number of flutes on tools #1 through 200 |

| #1801-#2000 | #1801-#2000 | Maximum recorded vibrations of tools 1 through 200 |

| #2001-#2200 | #2001-#2200 | Tool length offsets |

| #2201-#2400 | #2201-#2400 | Tool length wear |

| #2401-#2600 | #2401-#2600 | Tool diameter/radius offsets |

| #2601-#2800 | #2601-#2800 | Tool diameter/radius wear |

| #3000 | #3000 | Programmable alarm |

| #3001 | #3001 | Millisecond timer |

| #3002 | #3002 | Hour timer |

| #3003 | #3003 | Single block suppression |

| #3004 | #3004 | Override [FEED HOLD] control |

| #3006 | #3006 | Programmable stop with message |

| #3011 | #3011 | Year, month, day |

| #3012 | #3012 | Hour, minute, second |

| #3020 | #3020 | Power on timer (read only) |

| #3021 | #3021 | Cycle start timer |

| #3022 | #3022 | Feed timer |

| #3023 | #3023 | Present part timer (read only) |

| #3024 | #3024 | Last complete part timer (read only) |

| #3025 | #3025 | Previous part timer (read only) |

| #3026 | #3026 | Tool in spindle (read only) |

| #3027 | #3027 | Spindle RPM (read only) |

| #3028 | #3028 | Number of pallets loaded on receiver |

| #3030 | #3030 | Single block |

| #3032 | #3032 | Block delete |

| #3033 | #3033 | Opt stop |

| #3034 | N/A | Safe Run (read only) |

| #3196 | #3196 | Cell safe timer |

| #3201-#3400 | #3201-#3400 | Actual diameter for tools 1 through 200 |

| #3401-#3600 | #3401-#3600 | Programmable coolant positions for tools 1 through 200 |

| #3901 | #3901 | M30 count 1 |

| #3902 | #3902 | M30 count 2 |

| #4001-#4021 | #4001-#4021 | Previous block G-code group codes |

| #4101-#4126 | #4101-#4126 | Previous block address codes |

| #5001-#5006 | #5001-#5006 | Previous block end position |

| #5021-#5026 | #5021-#5026 | Present machine coordinate position |

| #5041-#5046 | #5041-#5046 | Present work coordinate position |

| #5061-#5069 | #5061-#5069 | Present skip signal position -X, Y, Z, A, B, C, U, V, W |

| #5081-#5086 | #5081-#5086 | Present tool offset |

| #5201-#5206 | #5201-#5206 | G52 work offsets |

| #5221-#5226 | #5221-#5226 | G54 work offsets |

| #5241-#5246 | #5241-#5246 | G55 work offsets |

| #5261-#5266 | #5261-#5266 | G56 work offsets |

| #5281-#5286 | #5281-#5286 | G57 work offsets |

| #5301-#5306 | #5301-#5306 | G58 work offsets |

| #5321-#5326 | #5321-#5326 | G59 work offsets |

| #5401-#5500 | #5401-#5500 | Tool feed timers (seconds) |

| #5501-#5600 | #5501-#5600 | Total tool timers (seconds) |

| #5601-#5699 | #5601-#5699 | Tool life monitor limit |

| #5701-#5800 | #5701-#5800 | Tool life monitor counter |

| #5801-#5900 | #5801-#5900 | Tool load monitor maximum load sensed so far |

| #5901-#6000 | #5901-#6000 | Tool load monitor limit |

| #6001-#6999 | #6001-#6999 | Reserved. Do not use. |

| #6198 | #6198 | NGC/CF flag |

| #7001-#7006 | #7001-#7006 | G110 (G154 P1) additional work offsets |

| #7021-#7026 | #7021-#7026 | G111 (G154 P2) additional work offsets |

| #7041-#7386 | #7041-#7386 | G112-G129 (G154 P3-P20) additional work offsets |

| #7501-#7506 | #7501-#7506 | Pallet priority |

| #7601-#7606 | #7601-#7606 | Pallet status |

| #7701-#7706 | #7701-#7706 | Part program numbers assigned to pallets |

| #7801-#7806 | #7801-#7806 | Pallet usage count |

| #8500 | #8500 | Advanced Tool Management (ATM) group ID |

| #8501 | #8501 | ATM percent of available tool life of all tools in the group |

| #8502 | #8502 | ATM total available tool usage count in the group |

| #8503 | #8503 | ATM total available tool hole count in the group |

| #8504 | #8504 | ATM total available tool feed time (in seconds) in the group |

| #8505 | #8505 | ATM total available tool total time (in seconds) in the group |

| #8510 | #8510 | ATM next tool number to be used |

| #8511 | #8511 | ATM percent of available tool life of the next tool |

| #8512 | #8512 | ATM available usage count of the next tool |

| #8513 | #8513 | ATM available hole count of the next tool |

| #8514 | #8514 | ATM available feed time of the next tool (in seconds) |

| #8515 | #8515 | ATM available total time of the next tool (in seconds) |

| #8550 | #8550 | Individual tool ID |

| #8551 | #8551 | Number of flutes of tools |

| #8552 | #8552 | Maximum recorded vibrations |

| #8553 | #8553 | Tool length offsets |

| #8554 | #8554 | Tool length wear |

| #8555 | #8555 | Tool diameter offsets |

| #8556 | #8556 | Tool diameter wear |

| #8557 | #8557 | Actual diameter |

| #8558 | #8558 | Programmable coolant position |

| #8559 | #8559 | Tool feed timer (seconds) |

| #8560 | #8560 | Total tool timers (seconds) |

| #8561 | #8561 | Tool life monitor limit |

| #8562 | #8562 | Tool life monitor counter |

| #8563 | #8563 | Tool load monitor maximum load sensed so far |

| #8564 | #8564 | Tool load monitor limit |

| #9000 | #9000 | Thermal comp accumulator |

| #9000-#9015 | #9000-#9015 | Reserved (duplicate of axis thermal accumulator) |

| #9016 | #9016 | Thermal spindle comp accumulator |

| #9016-#9031 | #9016-#9031 | Reserved (duplicate of axis thermal accumulator from spindle) |

| #10000-#10999 | N/A | General purpose variables |

| #11000-#11255 | N/A | 256 discrete inputs (read only) |

| #12000-#12255 | N/A | Discrete outputs |

| #13000-#13063 | N/A | Filtered analog to digital inputs (read only) |

| #13013 | N/A | Coolant level |

| #14001-#14006 | N/A | G110 (G154 P1) additional work offsets |

| #14021-#14026 | N/A | G110 (G154 P2) additional work offsets |

| #14041-#14386 | N/A | G110 (G154 P3-G154 P20) additional work offsets |

| #14401-#14406 | N/A | G110 (G154 P21) additional work offsets |

| #14421-#15966 | N/A | G110 (G154 P22-G154 P99) additional work offsets |

| #20000-#29999 | N/A | Settings |

| #30000-#39999 | N/A | Parameters |

| #32014 | N/A | Machine Serial Number |

| #50001-#50200 | N/A | Tool Type |

| #50201-#50400 | N/A | Tool material |

| #50401-#50600 | N/A | Tool Offset Point |

| #50601-#50800 | N/A | Estimated RPM |

| #50801-#51000 | N/A | Estimated Feedrate |

| #51001-#51200 | N/A | Offset Pitch |

| #51201-#51400 | N/A | Actually VPS Estimated RPM |

| #51401-#51600 | N/A | Work Material |

| #51601-#51800 | N/A | VPS Feedrate |

| #51801-#52000 | N/A | Approximate length |

| #52001-#52200 | N/A | Approximate diameter |

| #52201-#52400 | N/A | Edge Measure height |

| #52401-#52600 | N/A | Tool Tolerance |

| #52601-#52800 | N/A | Probe Type |

Bold entries indicate commonly used variables for production monitoring.

Note: Variable addresses for older Haas controllers can be found in the "Legacy Variable" column. NGC (Next Generation Control) variables are shown in the first column.

Configure Macro Variables in Adapter

To read macro variables, add a macros section to your Haas Serial adapter configuration:

{

"adapter": {

"mdcEnabled": 1

},

"macros": {

"opt-stop": 3033,

"last-m-code": 4113,

"part-timer": 3023,

"spindle-rpm": 3027,

"coolant-level": 13013,

"g54-x-offset": 5221,

"tool-1-life": 5701

}

}

How to Configure:

- In MachineMetrics, go to Assets → Machines

- Select your Haas machine

- Click on the Haas Serial adapter

- Add the JSON configuration above in the adapter settings JSON field

- Customize the macro names and variable numbers as needed

- Save changes

Macro Configuration Format:

- Key (left side): Data item name that will appear in MachineMetrics (use lowercase with hyphens)

- Value (right side): Haas macro variable number

Common Useful Variables:

{

"adapter": {

"mdcEnabled": 1

},

"macros": {

"opt-stop-enabled": 3033,

"block-delete-enabled": 3032,

"single-block-enabled": 3030,

"m30-count": 3901,

"part-timer-seconds": 3023,

"last-part-timer-seconds": 3024,

"current-tool": 3026,

"spindle-rpm-actual": 3027,

"power-on-hours": 3020,

"cycle-start-timer": 3021,

"feed-timer": 3022,

"coolant-level-percent": 13013

}

}

These macro variables will appear as data items in MachineMetrics alongside other machine data.

Tool Life Monitoring Example:

For tracking tool life counters and presets, use the tool life monitoring variables:

{

"adapter": {

"mdcEnabled": 1

},

"macros": {

"TLM_1_COUNT": 5701,

"TLM_1_PRESET": 5601,

"TLM_2_COUNT": 5702,

"TLM_2_PRESET": 5602,

"TLM_3_COUNT": 5703,

"TLM_3_PRESET": 5603,

"TLM_4_COUNT": 5704,

"TLM_4_PRESET": 5604,

"TLM_5_COUNT": 5705,

"TLM_5_PRESET": 5605

}

}

Variable Explanation:

- #5601-#5699: Tool life monitor limit (preset/maximum)

- #5701-#5800: Tool life monitor counter (current usage)

Example:

TLM_1_COUNT(Macro #5701) = Current count for Tool 1TLM_1_PRESET(Macro #5601) = Preset limit for Tool 1

If COUNT = 150 and PRESET = 500:

- Tool 1 is at 30% used (70% remaining)

Note: For detailed tool life monitoring setup and configuration, see the Tool Life Monitoring Guide.

Using Both MTConnect and Serial Together

For Next Gen Haas machines, the recommended setup is to use MTConnect as the primary adapter and Haas Serial as a secondary adapter to access macro variables.

Why Use Both?

- MTConnect provides comprehensive machine data (execution, program, speeds, positions, etc.)

- Haas Serial provides access to macro variables and system variables not exposed via MTConnect

- Combine to get the most complete data set

Setup Process

Step 1: Add MTConnect Adapter (Primary)

- Go to Assets → Machines

- Click Add Machine

- Configure as MTConnect (see Method 1 above)

- Connect to port 8082

- Save and verify data collection

Step 2: Add Haas Serial Adapter (Secondary)

- On the same machine, click Add Secondary Adapter

- Select adapter type: Haas Serial

- Enter connection details:

- Connection address:

[MACHINE-IP]:4001(e.g.,10.26.5.142:4001)- Use same machine IP as MTConnect, but port 4001

- Connection address:

- Enable Setting 143 on machine (set to 4001)

- Add macro variables configuration (JSON)

- Save adapter

Step 3: Create Transform to Prevent Conflicts

The Haas Serial connection may provide a RunStatus data item that conflicts with MTConnect's execution data item. Use a transform adapter to filter it out.

Create Transform Adapter:

- On the same machine, click Add Secondary Adapter

- Select adapter type: Transform

- Add this configuration:

version: 2

# Do NOT pass all data through automatically (use false to control what passes)

mtconnect-passthrough: false

# Deny the RunStatus from Haas Serial to prevent conflict with MTConnect execution

deny-keys:

- RunStatus

# Pull data items from parent adapters (MTConnect and Haas Serial)

declare-keys:

- execution # From MTConnect (primary execution state)

- program # From MTConnect

- tool # From MTConnect

- Sspeed # From MTConnect (spindle speed)

- opt-stop-enabled # From Haas Serial (macro variable)

- part-timer-seconds # From Haas Serial (macro variable)

- spindle-rpm-actual # From Haas Serial (macro variable)

- coolant-level-percent # From Haas Serial (macro variable)

# Output all declared data items

data-items:

- execution

- program

- tool

- Sspeed

- opt-stop-enabled

- part-timer-seconds

- spindle-rpm-actual

- coolant-level-percent

Important:

mtconnect-passthrough: falsemeans only declared keys are passed throughmtconnect-passthrough: truemeans all parent data passes through automatically (in addition to declared keys)- Use

falsewhen you want explicit control over which data items are output

- Save transform adapter

Result:

- MTConnect provides execution state (primary)

- Haas Serial provides macro variables

RunStatusis blocked to prevent conflicts- All data flows to MachineMetrics cleanly

Data Flow Diagram

Haas Next Gen Machine

│

├─→ Port 8082 (MTConnect)

│ └─→ execution, program, tool, speeds, positions, etc.

│

└─→ Port 4001 (Haas Serial/MDC)

└─→ opt-stop, part-timer, macro variables

│

└─→ Transform Adapter

└─→ Denies: RunStatus

└─→ Passes: macro variables

Final Output: Complete machine data from both sources

Troubleshooting

MTConnect Issues

Problem: Cannot reach MTConnect on port 8082

Solutions:

- Verify machine has Next Gen control

- Check MTConnect is enabled in machine settings

- Verify IP address is correct

- Test from browser:

http://[MACHINE-IP]:8082/current - Check firewall allows port 8082

- Ensure machine and Edge are on same network or routable

Problem: MTConnect shows "UNAVAILABLE" for many data items

Solutions:

- Machine may be powered off or in alarm state

- Wait for machine to fully boot up

- Clear any active alarms on machine

- Cycle power on machine control

Problem: Part count not incrementing

Solutions:

- Check Setting 57 (parts counter reset) on machine

- Verify machine is actually counting parts on screen

- Part counter may need to be configured in machine M-code program

- See Haas manual for part counter setup

Haas Serial Issues

Problem: No data from Haas Serial connection

Solutions:

- Next Gen: Verify Setting 143 is set to 4001 (not ON/OFF)

- Classic: Verify Setting 143 is ON

- Check IP address and port 4001 are correct

- Test connection with telnet:

telnet [IP] 4001 - Verify serial parameters match (38400, Even, 7, 1)

- Classic only: Check Moxa converter is powered and connected

Problem: Moxa converter not responding (Classic controls)

Solutions:

- Verify Moxa has power (LED should be lit)

- Check Ethernet cable connection to Moxa

- Use Moxa Device Search Utility to find Moxa IP

- Reset Moxa to factory defaults (hold reset button 10 seconds)

- Verify Moxa serial port settings match machine settings

Problem: Data comes through but looks garbled

Solutions:

- Serial parameters mismatch - verify all settings match exactly

- Check cable is not damaged

- Verify baud rate is 38400 on both machine and Moxa/adapter

- Ensure parity is EVEN (not NONE or ODD)

- Verify data bits are 7 (not 8)

Problem: Macro variables show "UNAVAILABLE"

Solutions:

- Check JSON configuration syntax is correct

- Verify macro variable numbers are valid (see reference)

- Some variables are read-only and may show UNAVAILABLE if condition not met

- Test with common variables like #3027 (spindle RPM) to verify connection

Connection Conflicts

Problem: Both MTConnect and Haas Serial show execution state but they conflict

Solution:

- Use transform adapter to deny

RunStatusfrom Haas Serial - Let MTConnect provide

executionas primary state - See "Using Both MTConnect and Serial Together" section above

Problem: Duplicate data items from MTConnect and Serial

Solution:

- Use transform adapter with

deny-keysto block duplicates - Decide which source is authoritative for each data item

- Keep MTConnect data for standard items, Serial only for macros

Additional Resources

Official Documentation

- Haas Operator's Manual - System Variables Reference (included with machine)

Related MachineMetrics Guides

- MTConnect Connectivity Guide - General MTConnect setup

- Transform Adapter Scripts Guide - Creating transforms to filter/combine data

- Machine Settings Guide - Configuring data mapping in MachineMetrics

Haas Resources

- Haas Operator's Manual (included with machine)

- Haas Setting 143 documentation

- Haas MTConnect implementation guide

Hardware Resources

- Hardware Buying Guide - Order Moxa converters and Edge devices

- Moxa NPort 5110 User Manual

- Moxa Device Search Utility (Windows software)

Quick Reference: Haas Connection Decision Tree

Do you have a Haas machine?

│

├─→ YES: What control type?

│ │

│ ├─→ Next Generation Control (2017+)

│ │ │

│ │ ├─→ Primary: MTConnect (port 8082)

│ │ │ └─→ Provides: execution, program, speeds, positions, alarms

│ │ │

│ │ └─→ Secondary (optional): Haas Serial (port 4001)

│ │ └─→ Provides: macro variables, system variables

│ │ └─→ Add transform to deny RunStatus

│ │

│ ├─→ Classic Control (pre-2017)

│ │ └─→ Haas Serial via RS-232 + Moxa converter

│ │ └─→ Setting 143 ON, 38400 baud, Even parity

│ │ └─→ Configure macro variables for additional data

│ │

│ └─→ Very Old (no Setting 143)

│ └─→ Use Digital I/O connectivity instead

│

└─→ NO: See other connectivity guides

Need help? Contact MachineMetrics Support at support@machinemetrics.com or ask Max AI in-app.