Machine Settings Guide

- Accessing Machine Settings

- Adding New Machines

- General Information Tab

- Production and Operations Tab

- Data Collection Tab

- Data Mapping Tab

- Data Rules Tab

- Warning and Failure Thresholds Tab

- Tool Monitoring and Integration Tabs

- Configuration Checklist

This guide defines how to configure Machine Settings in MachineMetrics and can be used to train an AI to generate configuration instructions.

1. Accessing Machine Settings

1.1 From the Machine Menu

- Open the machine menu on the left-hand side.

- Select the machine you wish to configure.

- Click the gear icon in the top-right corner.

You will see the following tabs:

- General Information

- Production and Operations

- Data Collection

- Data Mapping

- Data Rules

- Warning and Failure Thresholds

- Tool Monitoring (if Tool Anomaly Detection is purchased)

- Integration

1.2 From the Assets > Machines Page

You can also access settings and add machines via Assets → Machines:

- From the left-hand menu, expand Assets.

- Click Machines.

- To open settings for an existing machine:

- Select the machine in the list.

- Use the tabs at the top (Overview, Production, Operations, Data Mapping, Data Rules, Data Collection Methods, etc.).

- To change the edge device for a machine:

- Open the machine from this page.

- Use the control on the page to assign a different edge device.

- To duplicate a machine configuration:

- Use the Duplicate option on this page to copy an existing machine setup.

2. Adding New Machines

2.1 Add a Single Machine

- Go to Assets → Machines.

- Click Add Machine (top-right corner).

- Enter:

- Machine Name

- IP Address

- Edge Device

- If you need to add more than one machine individually:

- Use the + Add Machine button in the top-right to add more rows.

- Click Save and Connect.

MachineMetrics will:

- Use the IP Address to auto-detect the connection type (e.g., FANUC, Haas, MTConnect, etc.).

- Return you to the Machines page showing:

- Machine list

- Connection status

- IP address

- Collection method

For machines where automatic assignment fails:

- You will see a blue button labeled Needs connecting.

- Click Needs connecting to open the settings for that machine.

- In the bottom-right corner, under Data Collection Methods:

- Click Add.

- Select the correct collection method (e.g., Haas, MTConnect, OPC UA).

- Enter the connection address and adapter script if required.

- Click Save.

- The system will then attempt to connect to the machine using the provided details.

2.2 CSV Import (Bulk Add)

- Go to Assets → Machines.

- Click Add Machine.

- Select CSV Import.

- Prepare a CSV file with the following columns (case sensitive):

machineName(required)machineMake(optional)machineModel(optional)serial(optional)year(optional)edgeSerialNumber(optional)ipAddress(optional)

CSV Example:

machineName,machineMake,machineModel,serial,year,edgeSerialNumber,ipAddress

Mill-001,Haas,VF-3,12345,2020,U461122,192.168.1.10

Lathe-002,Mazak,QTN-250,67890,2019,,192.168.1.11

Grinder-003,Studer,S22,24680,2021,U461122,192.168.1.12

- Follow the on-page guidance to ensure:

- Column names match exactly (case sensitive).

- Required field

machineNameis present.

- Upload the CSV.

- Once the machines appear in the table, click Save and Connect.

MachineMetrics will:

- Attempt to determine the machine connection type for each machine using the IP Address.

- Mark any machines that require manual setup with Needs connecting.

For any machine that says Needs connecting:

- Click the button.

- Configure Data Collection Methods as described above.

- Click Save to trigger the connection attempt.

3. General Information Tab

Use this tab to define core attributes of the machine.

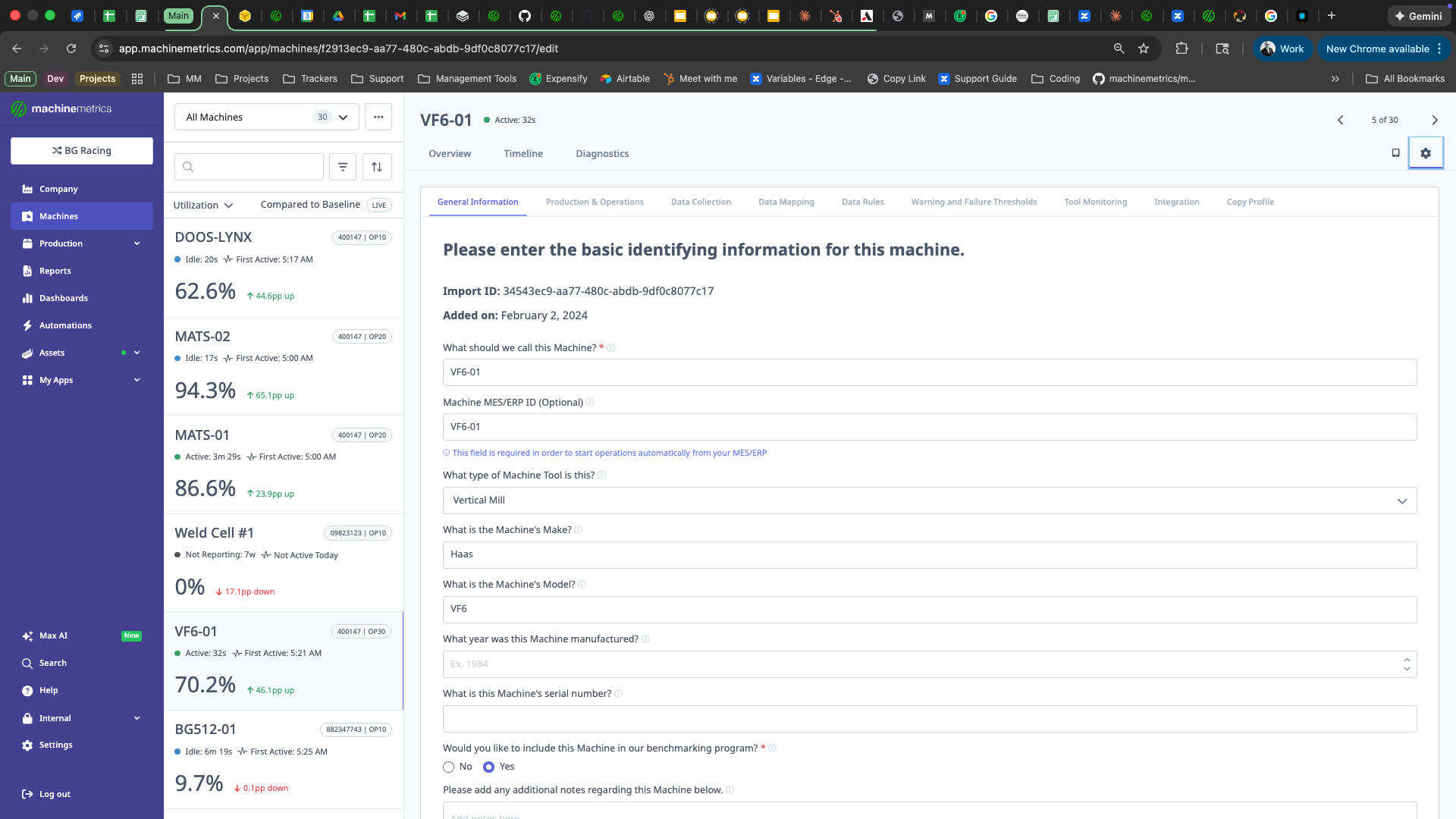

The General Information tab is where you enter basic identifying information for the machine, including machine name, ME/ERP ID, machine type, make, model, manufacturer, serial number, and whether to include the machine in benchmarking programs. This screenshot shows a sample machine (VF6-01) with its configuration details.

3.1 Core Fields

-

Machine ID

- System-generated identifier for the machine.

-

Date Added

- Timestamp when this machine was added to the account.

-

What should we call this machine?

- Human-friendly name and primary identifier for this machine.

- Use a naming convention meaningful to your operation.

-

What type of machine tool is this?

- Select the type:

- Mill

- Lathe

- CMM

- PLC

- Etc.

- Select the type:

-

What is the machine's make and model?

- Important for:

- Troubleshooting

- Support

- Determining likely connection methods

- Important for:

-

What year was the machine manufactured?

-

What is the machine's serial number?

- Useful if MachineMetrics needs to contact the machine tool builder on your behalf.

3.2 Benchmarking Program

- Include this machine in the benchmarking program?

- Enables anonymous comparison with all machines of the same type in MachineMetrics.

- Data (e.g., utilization) is anonymized and aggregated.

- Supports industry performance reporting without revealing customer identity.

3.3 Notes and Schedule

-

Notes regarding this machine

- Free-text field for:

- Setup notes (e.g., "in its own cell", "in a Fastems cell")

- Attached devices or automation

- Any information that helps with troubleshooting or context.

- Free-text field for:

-

Machine Schedule

- Assign the schedule this machine follows.

- Schedules are created in System Settings.

- Controls expected operating times and schedule-based reporting.

3.4 Controller and Decommission

-

Controller Make/Model

- Specify controller manufacturer and model.

- Supports:

- Connection selection

- Troubleshooting

-

Decommission

- Located at the bottom-left.

- Removes the machine from your account when it is no longer in service.

4. Production and Operations Tab

Configure operation detection and run creation.

4.1 Operation Matching Modes

For Ethernet-enabled machines or any machine with a program data item, available modes:

AutomaticAutomatic with Manual ConfigurationManualERP(if ERP integration is turned on)

The Operation Matching dropdown allows you to select how operations are matched: Automatic, Automatic (manual configuration), Manual, or ME/ERP (ERP ID Required). This determines how MachineMetrics identifies and tracks production runs.

These modes implement Automatic Production Matching (APM):

4.1.1 Automatic (APM2)

- MachineMetrics looks at the program header.

- It extracts what it believes is the correct part number.

- Reliability depends on:

- Program header consistency ("hygiene").

- Availability of program header data from the machine.

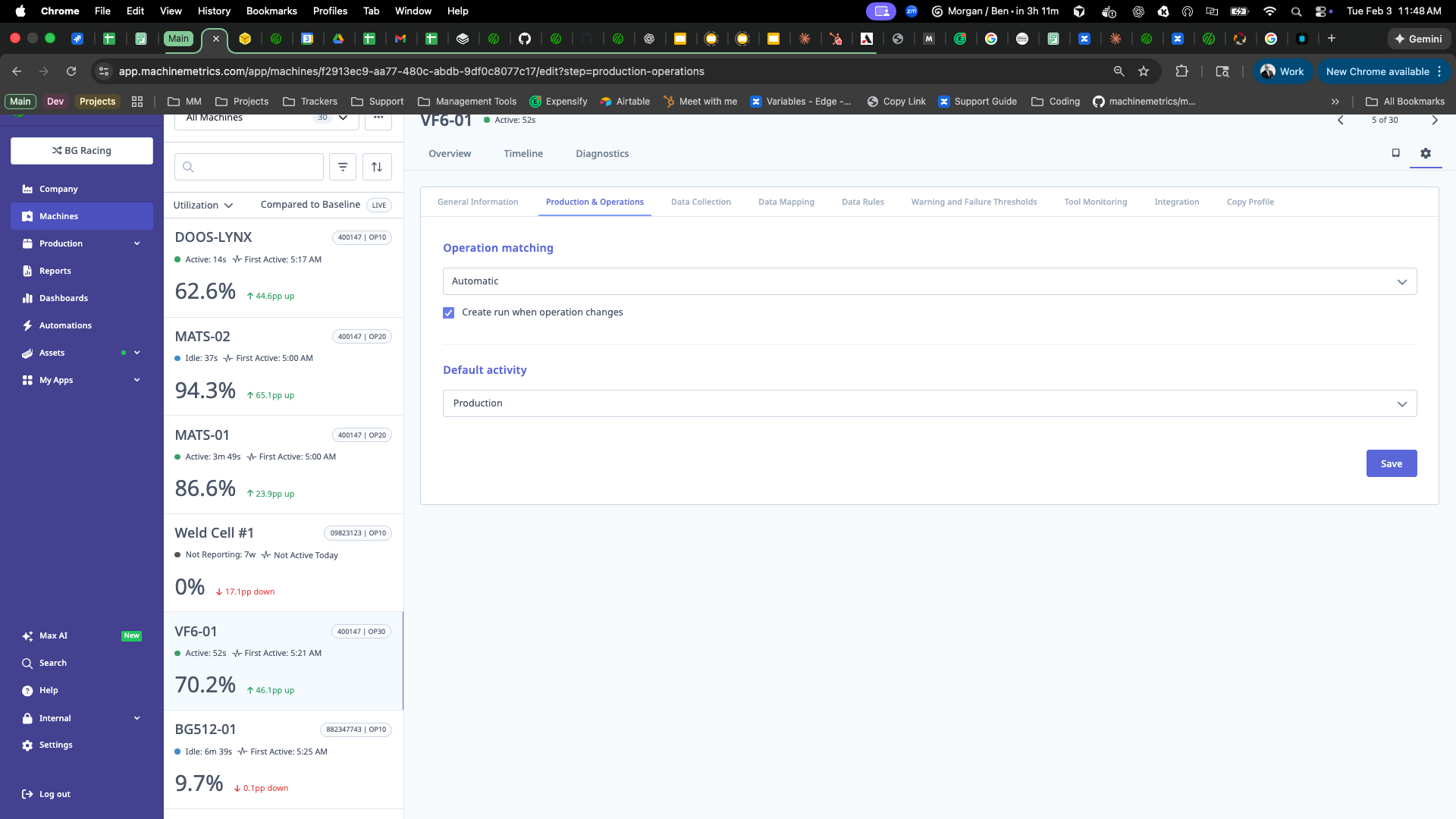

When set to Automatic mode, MachineMetrics automatically detects operations. You can enable "Create run when operation changes" checkbox to automatically create new production runs when the operation changes, and set the "Default activity" (typically "Production").

4.1.2 Automatic with Manual Configuration

Use when program headers:

- Are inconsistent, or

- Do not contain clean part/operation identifiers.

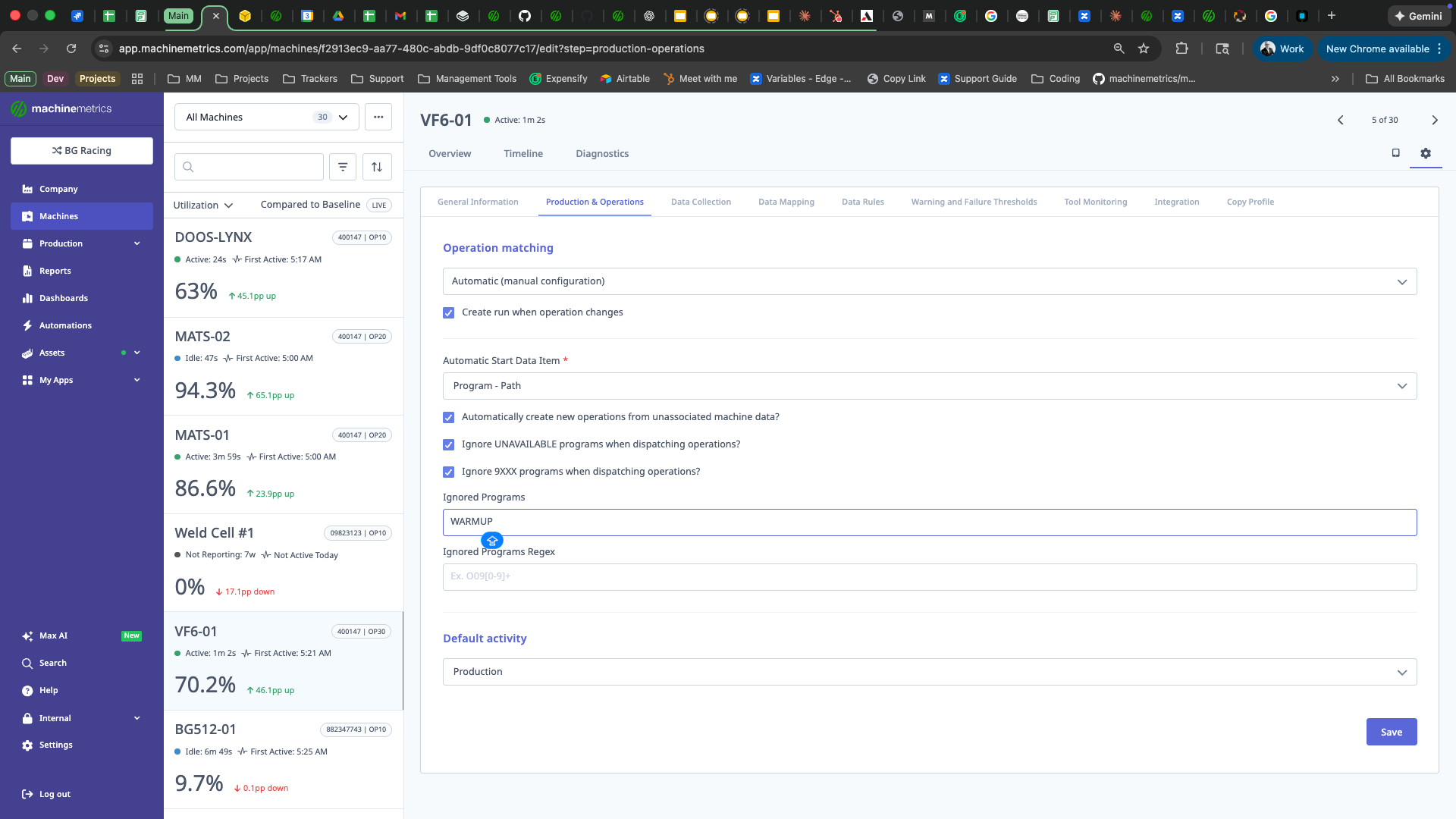

In Automatic (manual configuration) mode, you can specify the "Automatic Start Data Item" (e.g., Program - Path), enable options like "Create new operations from unassociated machine data", "Ignore UNAVAILABLE programs when dispatching operations", "Ignore RXX programs when dispatching operations", configure "Ignored Programs" (e.g., WARMUP), and set the "Default activity" (Production).

Configuration options:

-

Automatic Start Data Item:

- Choose which data item triggers a new operation:

- Program header

- Program number

- Custom data item built via a script

- Choose which data item triggers a new operation:

-

Custom Data Item via Script:

- Often uses regex to:

- Extract part numbers or operation codes from the program header.

- Clean and normalize values.

- Provides the highest accuracy when properly set up.

- Often uses regex to:

4.1.3 Manual

- Operations and runs:

- Are selected or created manually by operators.

- Suitable when:

- Program data is not reliable.

- You prefer operator-driven tracking.

4.1.4 ERP

- Available when an ERP integration is configured.

- Operations and runs are driven by ERP dispatching.

4.2 Run Creation on Operation Changes

-

Create run when operation changes:

- When enabled, MachineMetrics automatically:

- Creates a new production run whenever it detects a new operation.

- Recommended: Enabled for most machines.

- When enabled, MachineMetrics automatically:

-

When to disable:

- For pallet-change machines where:

- One part runs on one side and another part on a different side.

- You do not want a new run created on each pallet change.

- For pallet-change machines where:

4.3 Additional Options (Automatic with Manual Configuration)

When an Automatic Start Data Item is selected, additional options appear:

-

Create new operations from associated machine data

- Automatically create operations using associated data from the machine.

-

Ignore unavailable programs when dispatching operations

- Skips over unavailable programs instead of creating operations.

-

Ignore specific or high-numbered programs when dispatching operations

- Used to ignore:

- Warmup programs

- Changeover programs

- Cutoff programs

- Other non-production programs

- Regex examples:

- Ignore all program numbers over

8000or9000.

- Ignore all program numbers over

- Prevents:

- Creation of new operations for non-production programs.

- Creation of new runs when programs should be ignored.

- Used to ignore:

Use these filters to keep your operation history clean and accurate.

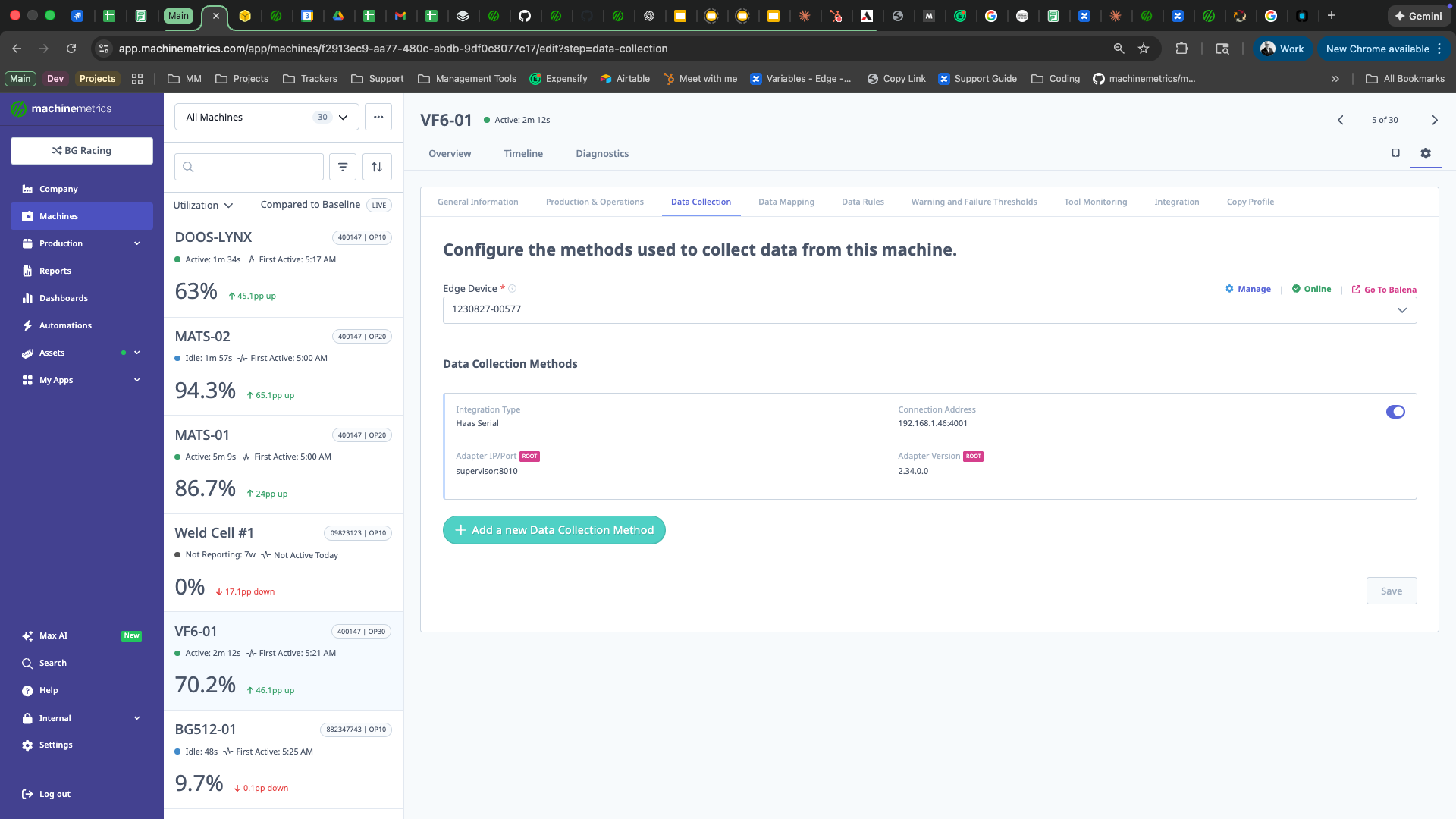

5. Data Collection Tab

Define how the system connects to and reads data from the machine.

The Data Collection tab shows the configured adapters for the machine. In this example, a Haas Serial integration is configured at IP 192.168.1.46:4001 with adapter version 2.34.0.0, along with a supervisor adapter at port 8036. This tab is where you add, manage, or delete data collection methods.

5.1 Adding a New Data Collection Method

- Open the Data Collection tab.

- Click Add a new data collection method.

- Use the dropdown to select one of the supported connection types, such as:

- Allen Bradley

- Brother

- Citizen M700

- Digital IoT

- Ethernet/IP (for Allen Bradley)

- FANUC FOCAS (Serial)

- Heidenhain

- IO-Link

- JSON HTTP

- Mitsubishi M70 / M80 / M800

- Modbus

- MQTT

- MTConnect Adapter

- MTConnect Agent

- OPC UA

- Siemens Step 7

- Universal Robot

- Transform

5.2 Machine Connections (All Types Except Transform)

For standard machine connections:

- You must provide:

- Connection address (IP, URL, or endpoint).

- Many connections require:

- An adapter script, which:

- Handles reading data from the controller or PLC.

- Publishes metrics in a format MachineMetrics understands.

- An adapter script, which:

For adapter scripts and examples:

- Refer to the Machine Connections section of the MachineMetrics Support Portal.

5.3 Transforms

Transforms are a special type of data collection entry:

- They do not connect directly to a machine.

- Instead, they process data coming from an existing adapter.

Transforms follow In → Process → Out:

-

In

- Declare keys that identify which incoming data items you will use.

-

Process

- Use variables and built-in operators to:

- Combine data.

- Perform calculations.

- Derive new signals.

- Use variables and built-in operators to:

-

Out

- Define output data items.

- These output items appear like standard data items and can be:

- Mapped in Data Mapping.

- Used for part counting, program logic, or analytics.

Transforms enable advanced customization of your machine data.

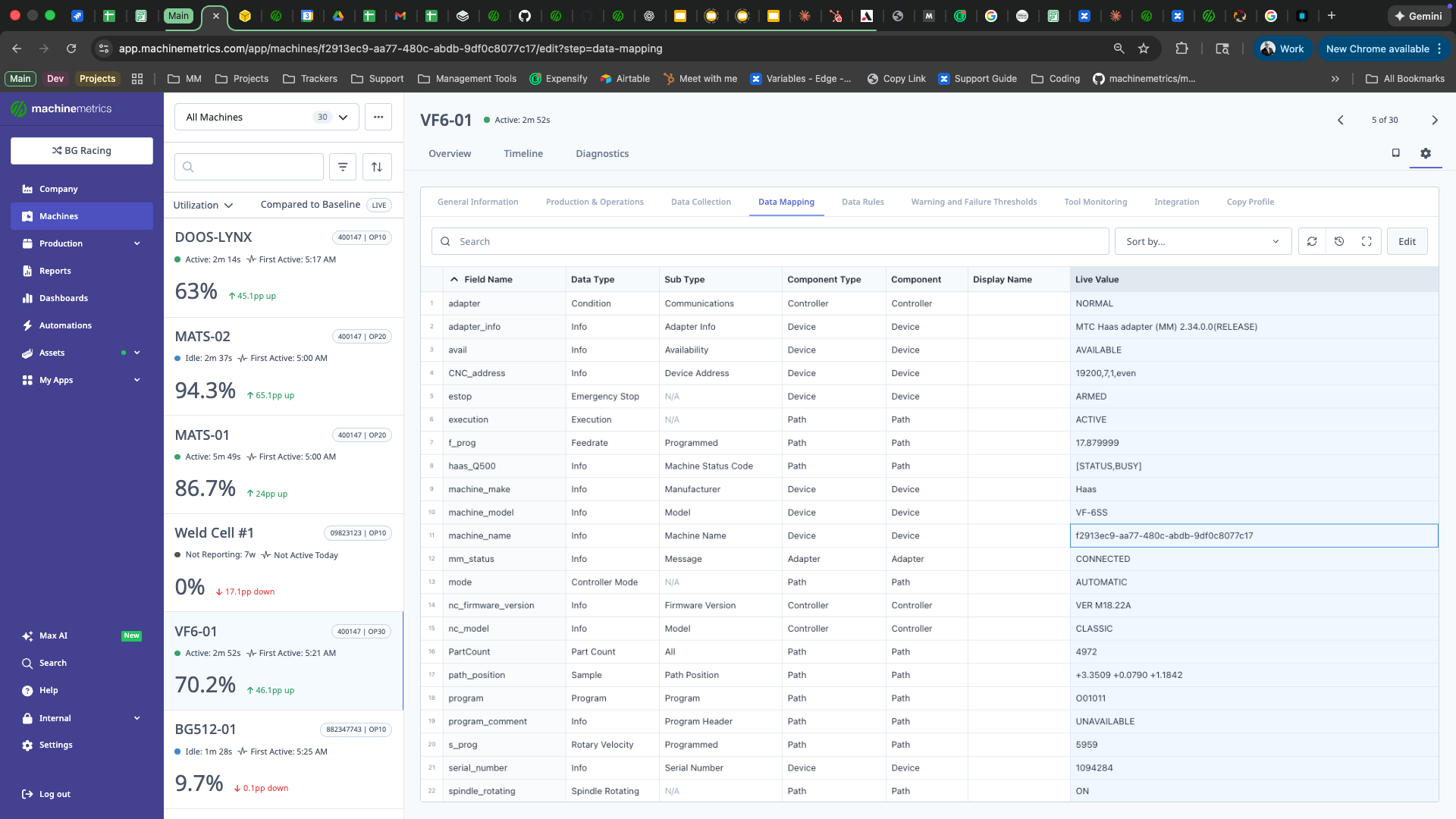

6. Data Mapping Tab

Configure how all incoming data items are labeled and used.

The Data Mapping tab displays all data items collected from the machine, showing field names, data types, sub types, component types, components, display names, and live values. This comprehensive view includes controller information, device details, and path data. You can search, sort, and edit data mappings to ensure all machine data is properly categorized and displayed.

6.1 Data Item Structure

The Data Mapping table shows:

-

Field Name

- Raw name from the machine or transform.

-

Data Type

-

Subtype

- Aids in organization and display in the Diagnostics tab.

-

Component / Component Type

- Indicates where the data belongs in the machine hierarchy.

6.2 Critical Mappings

For MachineMetrics features to work:

-

Program items:

- Must be mapped as

program. - Otherwise, they cannot be selected as:

- Automatic start data items in Production and Operations.

- Must be mapped as

-

Part Count items:

- Must be mapped as

part count. - Otherwise, they cannot be used as:

- The data item for counting parts.

- Must be mapped as

-

Execution items:

- Must be mapped as

execution. - This supports:

- Running/idle states

- Utilization calculations

- Must be mapped as

6.3 Unmapped Data Items

- Any data item shown as unmapped:

- Will not be displayed.

- Will not be tracked in MachineMetrics.

Be sure to map all important signals, especially those required for production tracking and KPIs.

6.4 Editing, Importing, and Exporting Mapping

-

Edit Item:

- Use the Edit option to change:

- Data Type

- Subtype

- Component mapping

- Save changes to apply.

- Use the Edit option to change:

-

Export / Import:

- Export current mappings to a file.

- Modify them externally (or generate via AI).

- Re-import the mapping file.

Typical workflow with PLCs:

- Export PLC tags (e.g., from Allen Bradley).

- Use an AI (e.g., Claude) to generate a MachineMetrics mapping file.

- Import the file to quickly set up mapping.

6.5 Available Data Types and Sub Types Reference

When mapping data items, you must select from the following Data Types and Sub Types. Capitalization is critical — use these values exactly as shown.

How to read this reference:

- Bold entries are top-level Data Types

- Indented entries beneath a Data Type are its available Sub Types

- Data Types with no indented entries have no Sub Types and are standalone signals

Part and Count Metrics

PartCount

- Total

- All

- Good

- Bad

- Target

- Remaining

ScrapCount (no sub types)

NonconformCount (no sub types)

CorrectionCount (no sub types)

Machine State Signals

Execution (no sub types)

SpindleRotating (no sub types)

Cutting (no sub types)

EmergencyStop (no sub types)

ControllerMode (no sub types)

Time Tracking

AccumulatedTime

- Total Operating Time

- Total Running Time

- Total Cutting Time

- Total Spindle Run Time

- Operating Time

- Running Time

- Cutting Time

- Spindle Run Time

EquipmentTimer

- Loaded Time

- Working Time

- Operating Time

- Powered Time

- Delay Time

EquipmentMode

- Loaded

- Working

- Operating

- Powered

- Delay

Program and Progress

ProgramProgress (no sub types)

Program

- Program

- Subprogram

- Program Name

- Subprogram Name

ProgramComment

- Program Comment

- Subprogram Comment

Speed and Feed

Feedrate

- Actual

- Commanded

- Jog

- Programmed

- Rapid

RotaryVelocity

- Actual

- Commanded

- Programmed

Override

- Rotary Velocity

- Feed

- Rapid Feed

- Jog Feed

Variables and Registers

Variables

- Common

Register (no sub types)

Bit (no sub types)

MacMan

- Panel History

OutputSignal

- Dry Run

- Machine Lock

Process Measurements

Amplitude

- Actual

- Target

Flow

- Actual

- Target

Pressure

- Actual

- Target

- Lower Target

- Upper Target

Humidity

- Absolute

- Relative

- Specific

CutSize

- Length

- Radial

Condition Monitoring

Condition

- Position

- Temperature

- Load

- Actuator

- Angle

- Pressure

- Level

- Communications

- Hardware

- System

- Motion Program

- Logic Program

Sample Data Type

The Sample data type is used for analog sensor readings and has the most sub types:

Sample

- Acceleration

- Angular Acceleration

- Angular Velocity

- Amperage

- Angle

- Axis Feedrate

- Boolean

- Clock Time

- Concentration

- Conductivity

- Displacement

- Electrical Energy

- Fill Level

- Flow

- Frequency

- Length

- Linear Force

- Load

- Mass

- Path Feedrate

- Path Position

- PH

- Position

- Power Factor

- Pressure

- Resistance

- Rotary Velocity

- Sound Level

- Strain

- Surface Speed

- Temperature

- Tilt

- Tool Length

- Tool Radius

- Torque

- Volt Ampere

- Volt Ampere Reactive

- Velocity

- Viscosity

- Voltage

- Wattage

- Current Transducer

- Sensor 1

- Sensor 2

- Sensor 3

- Sensor 4

- Sensor 5

- Sensor 6

- Amplitude

- Custom

Info Data Type

The Info data type is used for discrete/event-based information and status values:

Info

- Actuator State

- Active Axes

- Availability

- Axis Coupling

- Axis Interlock

- Axis State

- Block

- Chuck Interlock

- Chuck State

- Controller Mode

- Coupled Axes

- Direction

- Display Language

- Door State

- End Of Bar

- Firmware Version

- Functional Mode

- Interface State

- Line

- Material

- Manufacturer

- Message

- Model

- Operator ID

- Pallet ID

- Part ID

- Part Number

- Path Mode

- Power State

- Program

- Program Edit

- Program Edit Name

- Program Comment

- Program Header

- Rotary Mode

- Serial Number

- Spindle Interlock

- Spindle Mode

- Tool Asset ID

- Tool Number

- Version

- Workholding ID

- Block Delete

- Coolant

- Dry Run

- Operation Mode

- Optional Stop

- Reset

- Single Block

- Machine Lock

- Tool Group

- Tool Suffix

- Sequence Number

- Unit Number

- Workpiece

- Number Active Axes

- Loaded Program Name

- Internal Coolant

- External Coolant

- System Type

- Adapter Info

- Device Address

- Machine Name

- Machine Status Code

- Message Event Code

- Downtime Code

- Cycle Rate

- Work Counter Codes

- Scan Interval

- Interlock

- Tool Cuts

- Operation Count

- Chuck Select

- Cut Area

- Calibration Interlock

- Operator Interlock

- Rework Count

- Cutting Mode

- Supervisor Override

- Cycle Start

- Custom

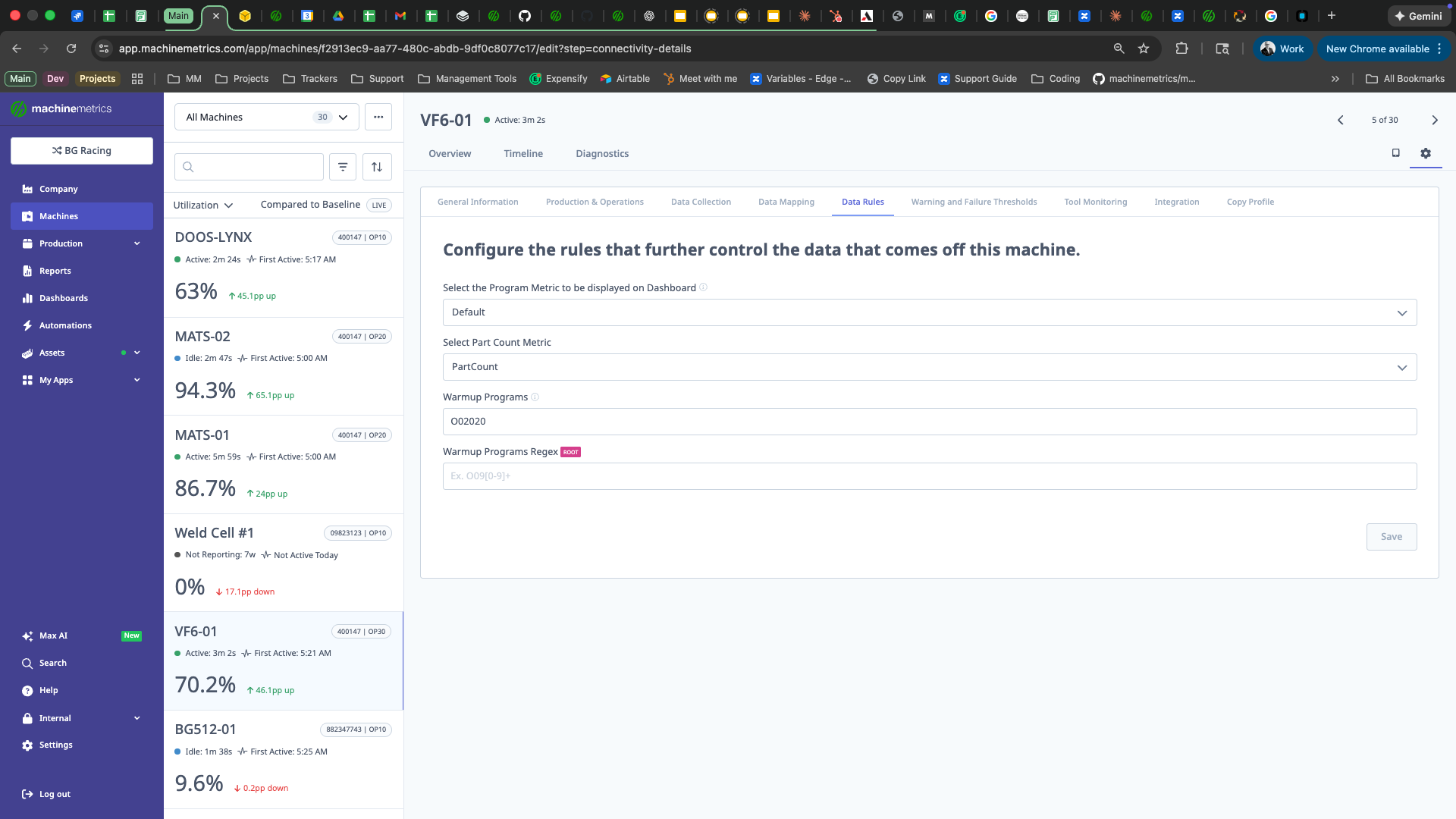

7. Data Rules Tab

Control primary metrics used for dashboards and reporting.

The Data Rules tab allows you to configure which metrics are displayed on dashboards and shop floor boards. Key settings include selecting the Program Metric (Default), Part Count Metric (PartCount), defining Warmup Programs (O00020), and specifying Warmup Programs Regex patterns. These rules control how production data is interpreted and displayed.

7.1 Program Metrics

- Select which program-related metric to display on:

- Dashboards

- Shop floor boards

7.2 Part Count Metric (Most Important Setting)

- Select Part Count Metric:

- Decide which data item is the authoritative part counter.

Available Options:

The dropdown includes several part count options based on your machine's available data items and configuration:

- Default (part_count, part_count2, total_part_count, total_part_count2)

- Production Run

- Virtual Part Counter

- Manual Counter

- Haas M30-Counter (for Haas machines)

How to Choose the Right Option

Default (Standard Part Count) - Most Common

This is the standard option and uses the machine controller's built-in part counter.

When to use:

- Machine has a reliable built-in part counter

- Controller properly increments the counter

- No double-counting issues

Common data items:

part_count- Primary counter from controllerpart_count2- Secondary counter (if machine has multiple paths)total_part_count- Accumulated total countertotal_part_count2- Secondary accumulated counter

⚠️ Avoiding Double Counts:

If you experience double counts, it's likely because multiple part count paths are being counted. In this case:

- Identify which path to count: Check if your machine has Path 1/Path 2 or multiple counters

- Select the specific counter: Choose

part_count(Path 1) ORpart_count2(Path 2), not both - Verify in Data Mapping: Ensure only ONE counter is mapped as the part count data item

Common scenarios:

- Mill-turn lathes with two paths: Select Path 1 (

part_count) unless Path 2 is your primary production path - Machines with multiple spindles: Choose the counter that represents completed parts, not work-in-progress

Haas M30-Counter - For Haas Machines with Double Counting

When to use:

- You have a Haas machine

- You're experiencing double counting issues

- Machine has multiple M30 counters

Why this option exists:

Haas mills typically have two M30 counters in their control. If both counters are mapped, the system will double-count each finished part.

Solution:

- Select "Haas M30-Counter" from the dropdown

- This tells the system to use only M30 Counter #1

- Prevents duplicate part counts

Alternative fix:

- Go to Data Mapping tab

- Unmap one of the M30 counters

- Keep only M30 Counter #1 mapped as part count

Virtual Part Counter (VPC) - AI-Powered Counting

When to use:

Use VPC when your machine does not have a reliable part counter or when controller part counts are:

- Missing or unavailable

- Inconsistent or unreliable

- Incorrectly programmed

- Different across similar machines in your fleet

What is Virtual Part Counter?

VPC uses artificial intelligence to automatically detect part completions by analyzing real-time machine signals:

- Tool number sequences

- Program execution states

- Machine activity patterns

- Controller mode changes

Instead of relying on the machine's built-in counter, VPC learns each machine's unique cycle patterns and counts parts automatically.

Key Benefits:

- No programming required: Works without configuring controller-specific part counting logic

- Self-learning: Automatically adapts to production changes

- Real-time accuracy: Counts parts as cycles complete

- Fleet-wide consistency: Standardizes part counting across different machine types

Requirements for VPC:

✅ Machine must have:

- Advanced controller with reliable data items (tool numbers, execution state, controller mode, program numbers)

- Connection via FANUC FOCAS, MTConnect, OPC-UA, or similar protocol

- Machine must output tool number data

- Not supported: I/O-only connections

✅ Production must have:

- Job tracking enabled (APM, ShopPulse, or ERP-driven)

- 3+ repetitive cycles per job

- Cycle times under 1 hour

Enabling Virtual Part Counter:

- Navigate to Machine Settings (gear icon) → Data Rules tab

- Find "Select Part Count Metric" dropdown

- Select "Virtual Part Counter" from the list

- Click "Save"

What Happens Next:

- VPC activates immediately

- For ongoing jobs: VPC starts counting after a brief warmup period (3-10 cycles)

- For new jobs: VPC learns from first few cycles, then backfills counts

- Counts appear in real-time on dashboards, reports, and operator tablets

Warmup Period:

- New jobs (never seen before): VPC needs to observe a few cycles before counting accurately

- Typical warmup: 3-10 cycles depending on complexity

- During warmup: Counts may not appear immediately but will backfill once model is confident

- Established jobs: No warmup needed; VPC counts from first cycle

Validation:

Check VPC accuracy using:

- Timeline View: Verify part count increments align with cycle completions

- Job Run Comparison: Compare VPC totals to manual hand counts

- Production Reports: Review counts in reports to ensure accuracy

When VPC May Not Work:

- Machines connected via Digital I/O only

- Machines that don't output tool number data

- Jobs with fewer than 3 repetitive cycles

- Cycle times exceeding 1 hour

- Non-repetitive one-off parts

Troubleshooting VPC:

| Issue | Solution |

|---|---|

| No counts appearing | • Verify job tracking is enabled • Check machine data: Tool number, execution state available? • Confirm 3+ repetitive cycles exist • Wait for warmup period on new jobs |

| Counts seem inaccurate | • Validate against Timeline view • Check cycle consistency • Verify cycle time under 1 hour • Compare to hand counts |

| VPC stopped counting mid-job | • Check machine connectivity • Verify job didn't change • Look for data gaps in Timeline |

Reverting to Controller Part Count:

If VPC doesn't work for your machine:

- Return to Machine Settings → Data Rules

- Change "Select Part Count Metric" back to your controller part count data item

- Click "Save"

Production Run - For Machines with Manual Interventions

When to use:

- Production includes frequent off-runs (setup, testing, trials)

- Operators make many manual interventions

- You want to count one cycle per production run change (not individual parts)

What it does:

Counts 1 cycle each time a production run changes, rather than counting every part.

Best for:

- Customers with high mix/low volume production

- Shops with significant setup and trial runs

- Machines where operators frequently stop/start/adjust between good parts

Example scenario:

- Operator sets up machine and runs 5 test parts (not counted)

- Operator starts production run for Job #123 → Count increments by 1

- Machine produces 50 parts on that run → Still shows count of 1

- Operator changes to Job #456 → Count increments by 1 (now total is 2)

Not recommended for:

- Standard part counting needs

- High-volume production where individual part counts matter

- Tracking actual quantities produced

Manual Counter - For Manual Stations Only

When to use:

- Machine is configured as a Manual Station in MachineMetrics

- Operators manually track production (no automated counter)

What it does:

Allows operators to manually enter part counts through the ShopPulse interface.

Availability:

- Only available on machines configured as Manual Stations

- Not available on CNC machines or automated equipment

How it works:

- Operator completes parts at manual station

- Operator enters count via ShopPulse tablet/interface

- System records manual count for reporting

See Also:

- Manual Stations Setup Guide for configuring manual workstations

7.3 Troubleshooting Double Counts

If you see duplicate or double part counts:

Step 1: Identify the Issue

- Check if machine has multiple counters (Path 1/Path 2, multiple M30s, multiple spindles)

- Look at Data Mapping tab - how many data items are mapped as "part count"?

- Check Data Rules tab - which part count metric is selected?

Step 2: Fix the Root Cause

Solution A - Use Data Rules (Recommended):

- Go to Data Rules tab

- Change "Select Part Count Metric" to the specific counter you want:

- For Haas machines: Select "Haas M30-Counter"

- For Path machines: Select

part_count(notpart_count2) - For dual-spindle: Select the primary spindle counter

- Save changes

Solution B - Fix Data Mapping:

- Go to Data Mapping tab

- Find all data items mapped as "part count"

- Unmap the secondary/duplicate counters

- Keep only ONE counter mapped as part count

- Save changes

Step 3: Verify Fix

- Watch machine Timeline for next few cycles

- Confirm part count increments by 1 (not 2) per completed part

- Check dashboards and reports show correct counts

7.4 Warmup Programs

Define program names or patterns that should be excluded from production counting and reporting.

What are Warmup Programs?

Warmup programs are non-production programs that operators run to prepare the machine, such as:

- Machine warmup routines

- Tool setter programs

- Calibration programs

- Test programs

- Setup verification programs

Why exclude them?

These programs should not be counted as production because they:

- Don't produce parts

- Artificially inflate cycle counts

- Skew production metrics and reports

- Create confusion in dashboards

How to Configure:

Option 1: Exact Program Names

- Enter specific program names (e.g.,

O00020,WARMUP,SETUP01) - Separate multiple programs with commas

- These will be excluded from production metrics

Option 2: Regex Patterns

- Use Warmup Programs Regex field for pattern matching

- Example patterns:

^O0002.*- Excludes all programs starting with O0002.*WARMUP.*- Excludes any program containing "WARMUP"^(SETUP|TEST|CALIB).*- Excludes programs starting with SETUP, TEST, or CALIB

Example:

- Warmup Programs:

O00020, TOOL_SETTER - Warmup Programs Regex:

^SETUP.*

This configuration excludes:

- Programs named exactly "O00020" or "TOOL_SETTER"

- Any program starting with "SETUP" (SETUP01, SETUP_MILL, etc.)

See Also:

- System Settings Guide - Virtual Part Counter for detailed configuration

- Production Analytics Guide for using part count data in reports

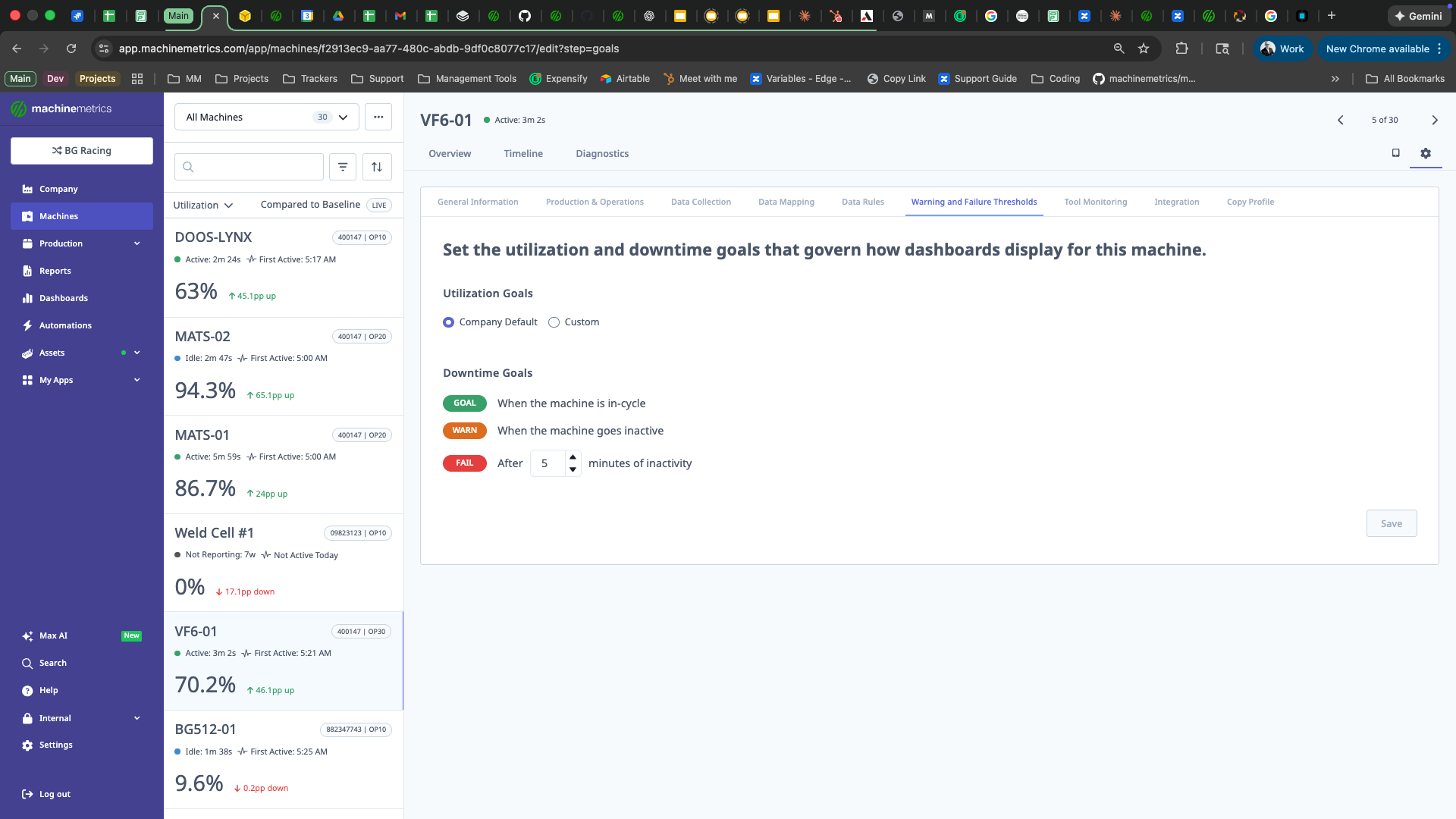

8. Warning and Failure Thresholds Tab

Configure machine status colors based on performance or condition thresholds.

The Warning and Failure Thresholds tab sets the utilization and downtime goals that determine machine status colors on dashboards. In this example, utilization goals use Company Default settings, and downtime goals are configured with GOAL (green) when in-cycle, WARNING (orange) when inactive, and FAIL (red) after 5 minutes of inactivity. These thresholds help quickly identify underperforming machines.

8.1 Status Colors

Define the rules that determine when the machine appears:

- Green – Healthy / within target thresholds.

- Orange – Warning / approaching a limit.

- Red – Failure or outside acceptable thresholds.

8.2 Per-Machine vs Company Default

You can:

- Use company default thresholds:

- For consistent behavior across all machines.

- Or configure machine-specific thresholds:

- When machines have unique performance expectations or capabilities.

9. Tool Monitoring and Integration Tabs

Appear based on enabled features and purchased modules.

9.1 Tool Monitoring

- Visible when Tool Anomaly Detection is purchased.

- Use this tab to:

- Configure tool monitoring parameters.

- Define thresholds for detecting anomalies.

- Adjust alerting behavior related to tool health.

9.2 Integration

- Manage external integrations affecting this machine, such as:

- ERP systems

- Other third-party systems

- Actual options depend on:

- Which integrations are enabled for your account.

10. Configuration Checklist

Use this checklist when setting up or auditing a machine in MachineMetrics:

-

Machine added via Assets → Machines

-

For CSV imports, columns are correctly formatted (case sensitive):

machineName(required),machineMake,machineModel,serial,year,edgeSerialNumber,ipAddress(all optional exceptmachineName) -

System attempted auto-detection of connection type after Save and Connect

-

Any machines labeled Needs connecting have:

- Data Collection Method manually set

- Connection address entered

- Adapter script configured (if needed)

-

Machine appears with correct connection status, IP, and collection method

-

General Information:

- Machine name, type, make, model, year, serial set

- Machine schedule assigned

- Benchmarking participation decided

- Notes field updated with setup and context

- Controller make/model entered

-

Production and Operations:

- Appropriate Operation Matching mode selected (Automatic / Automatic with Manual Configuration / Manual / ERP)

- Automatic Start Data Item configured (if applicable)

- Regex or scripts created for clean operation identification (if needed)

- "Create run when operation changes" set correctly (disabled for pallet-change edge cases)

- Filters for ignored programs (warmup, changeover, cutoff, 8000/9000+ ranges) applied as needed

-

Data Collection:

- Correct connection type selected (FANUC, MTConnect, OPC UA, etc.)

- Connection address verified

- Adapter script configured and working

- Transforms configured where needed (In → Process → Out)

-

Data Mapping:

- Program items mapped as

program - Part count items mapped as

part count - Execution items mapped as

execution - Important signals not left unmapped

- Mapping exported/imported if using AI-generated mapping from PLC tags

- Program items mapped as

-

Data Rules:

- Program metric selected for dashboards

- Select Part Count Metric set to the correct option:

- Default (part_count) for standard controller counting

- Haas M30-Counter if experiencing double counts on Haas machines

- Virtual Part Counter if controller counter is unreliable

- Production Run for high mix/low volume with manual interventions

- Manual Counter for manual stations only

- Verified no double counting (only one counter selected, check Data Mapping)

-

Warning and Failure Thresholds:

- Machine-specific or company default thresholds chosen

- Status color rules (green/orange/red) aligned with operational expectations

-

Tool Monitoring (if licensed):

- Tool anomaly detection configured

- Tool thresholds defined

-

Integration:

- ERP and other integrations configured (if applicable)

- Operation matching mode set to ERP where required

Related Articles

- Connectivity Overview — Choose the right connection method

- FOCAS Connectivity Guide — Fanuc machine connections

- MTConnect Connectivity Guide — MTConnect protocol setup

- OPC-UA Connectivity Guide — OPC-UA configuration