Digital I/O

Digital I/O & Modbus TCP Connectivity Guide

- Overview

- Current I/O Hardware

- Retired Hardware

- Understanding Current Transducers

- Signal Selection Strategy

- Sealevel eI/O-170 Installation

- WISE-4050 Installation & Configuration

- Modbus TCP Addressing

- Comprehensive Adapter Script Examples

- Machine-Specific Integrations

- Troubleshooting

- Best Practices

- Additional Resources

- Getting Help

Overview

What is I/O Connectivity?

I/O (Input/Output) connectivity is used when we need to connect machines that do not have Ethernet or a communication protocol available. This is typically our approach for older machines that predate modern networked controls.

How It Works:

MachineMetrics uses a piece of hardware (typically a Sealevel or WISE device) installed in the machine's electrical cabinet. This hardware module connects to electrical signals from the machine to monitor activity and production.

Our Standard Approach:

- Utilization Signal (Machine Activity):

- Install a current transducer (CT) on a cable drawing current

- Typically attached to the spindle motor cable

- Detects when the machine is running vs. idle by monitoring motor current

- Part Count Signal:

- Capture a signal that indicates when a part is complete

- Lathes: Often use bar feed signal

- Mills: Often use fixture clamp signal or pallet changer

- Other machines: Part eject, part counter relay, etc.

The hardware module reads these electrical signals and sends the data to MachineMetrics over your network using Modbus TCP protocol.

When to Use I/O

Use I/O connectivity when:

- Machine does not support modern protocols (FOCAS, MTConnect, OPC-UA)

- Older legacy equipment (pre-2000 machines)

- Simple machine tools without networked controls

- Non-CNC machines (press brakes, injection molding, grinders, assembly equipment)

- Equipment with accessible electrical signals but no data interface

Key Technical Concepts

Understanding these terms will help as you configure I/O connectivity:

- Wet Contact: Signal provides its own voltage source (e.g., 24VDC output from PLC)

- Dry Contact: Simple switch closure, requires external voltage source

- Current Transducer (CT): Sensor that outputs proportional voltage or current based on AC motor current

- Optically Isolated: Electrical isolation between input and system ground (3000VDC+ typical)

- Modbus TCP: Industry-standard digital protocol for reading/writing data over Ethernet

Current I/O Hardware

Sealevel eI/O-170E / eI/O-170PoE

MachineMetrics' exclusive I/O solution for all new installations. We sell and support only this model.

Sealevel eI/O-170 Ethernet I/O Module - A compact DIN-rail mounted device with digital inputs and outputs for connecting to machine signals. This module communicates via Modbus TCP and is commonly used for monitoring machine utilization through current transducers and capturing part counts from machine signals.

Specifications

Analog Inputs (8 channels):

- Voltage Ranges: 0-5V, 0-10V, ±5V, ±10V (software configurable)

- Resolution: 12-bit (4096 counts, 0.00244V per count at 10V range)

- Input Impedance: 100kΩ

- Channels: 8 single-ended OR 4 differential

- Typical Use: Current transducers (analog 0-10V CT models)

Digital Inputs (2 channels - Opto 1 & Opto 2):

- Type: Dry contact sensing (internally powered)

- Isolation: 1000VDC optical isolation

- Source Current: 12mA max

- Wiring: Connect switch/contact between input and common terminal

- ⚠️ CRITICAL: These inputs SOURCE current. DO NOT apply external voltage.

Power Options

Standard Model (eI/O-170E):

- Power: 9-30VDC, 3W typical

- Screw terminals on side of unit

- Use 24VDC shop power

Power over Ethernet (eI/O-170PoE):

- IEEE 802.3af-2003 PoE (Class 0)

- No separate power supply needed

- Single cable for power and data

- Requires PoE switch or injector

Physical Specifications

- Size: 4.5" L × 3.5" W × 1.3" H

- Mounting: DIN rail clip included (35mm rail)

- Terminals: 3.5mm removable screw terminals

- Status LEDs:

- Power (Green): Lights when powered

- Act (Green): Blinks during Modbus TCP activity

- Operating Temp: -40°C to 70°C

Purchasing

- Order from: shop.machinemetrics.com

- MachineMetrics provides pre-configured units

- Full technical support included

Advantech WISE-4050

Preferred wireless I/O solution that customers source directly from Advantech or distributors.

Advantech WISE-4050/LAN Ethernet I/O Module - Wired version with 4 digital inputs. The module features terminal connections for easy wiring and supports Modbus TCP communication. This is the LAN (wired Ethernet) variant; a wireless WiFi version (WISE-4050) is also available.

Specifications

Model: WISE-4050 (Wireless) or WISE-4050/LAN (Wired Ethernet)

Digital Inputs (4 channels):

- Type: Optically isolated

- Voltage Range: 10-50VDC

- Isolation: 3000VDC (optical)

- Wet Contact Compatible: Yes (10-50VDC)

- Dry Contact Compatible: Yes (requires external power)

Wireless Specifications (WISE-4050)

WiFi:

- Standard: IEEE 802.11 b/g/n

- Frequency: 2.4 GHz

- Range: Up to 150m (line of sight)

- Security: WEP, WPA, WPA2-PSK

- Modes: Infrastructure or AP mode

Network Configuration

Default Settings:

- Wireless AP Mode: SSID "WISE-4050-XXXXXX" (last 6 of MAC)

- Default IP: 10.0.0.1 (AP mode) or DHCP (Infrastructure mode)

- Default Login: root / 00000000 (8 zeros)

- Modbus Port: 502

- Web Interface: http://[IP-address]

Sourcing WISE-4050

Purchase Options:

- Direct from Advantech: www.advantech.com

- Distributors: DigiKey, Mouser, Newark, Arrow

- Typical Price: $150-250 USD

Part Numbers:

- WISE-4050: Wireless version

- WISE-4050/LAN: Wired Ethernet version

Additional Items Required for Wireless WISE-4050:

- Antenna extension cable (customer must purchase)

- Type: RP-SMA or compatible with WISE-4050 antenna connector

- Length: 1-3 feet recommended

- Features: Look for cables with magnetic base antenna for easy mounting

- Connects module inside cabinet to antenna outside cabinet

- Installation requirement: Hole must be drilled in electrical cabinet for external antenna mounting

Note: Wireless WISE-4050 requires antenna to be mounted externally to the electrical cabinet for proper WiFi signal reception. See Installation section for details.

Retired Hardware

LabJack T4/T7 (Hardwired)

⚠️ RETIRED: No longer sold by MachineMetrics. Existing installations fully supported.

If you already have these modules, they will continue to work with full MachineMetrics support. Analog voltage-based (0-40VDC) configuration.

LabJack U3 (Wireless)

⚠️ RETIRED: No longer sold by MachineMetrics. Existing installations fully supported.

Use Advantech WISE-4050 for new wireless installations.

Understanding Current Transducers

Types of Current Transducers

There are two types of CTs for different applications:

1. Analog Output CT (0-10VDC)

For use with Sealevel eI/O-170 Analog Inputs

Specifications:

- Input: 0-100A AC (or 0-200A for larger motors)

- Output: 0-10VDC (proportional analog voltage)

- Example: 50A motor current = 5VDC output

- Self-powered: No external power needed

Common Models:

- NK Technologies AT Series

- CR Magnetics CR5410

- Veris H Series

Wiring to eI/O-170:

CT (+) output → AN1 terminal

CT (-) output → AG terminal (analog ground)

Use Cases:

- Spindle motor monitoring (main utilization signal)

- Live tooling head monitoring

- Axis drive monitoring (Z-axis, etc.)

- Any motor-driven activity detection

2. Dry Contact Output CT (Switch Closure)

For use with Sealevel eI/O-170 Digital Inputs (Opto 1 & Opto 2)

Specifications:

- Input: 0-100A AC (adjustable setpoint)

- Output: Dry contact closure when current exceeds setpoint

- Requires: External voltage source for switch sensing

- Adjustable Trip Point: Set threshold for switch activation

Common Models:

- NK Technologies AS2 Series

- Veris H800 Series with switch output

Wiring to eI/O-170 Digital Input:

External 24VDC (+) → One side of CT switch output

Other side of CT switch → Opto 1 terminal

COM terminal → External 24VDC (-)

Use Cases:

- Simple on/off detection (machine running or not)

- When analog resolution not needed

- Cost-effective solution

Installing a Current Transducer

Step 1: Identify Motor to Monitor

- Usually spindle motor drive

- Could be live tooling head

- Could be axis drive (Z-axis for lathes)

- For multi-spindle: CT on each spindle

Step 2: Access Motor Power Wires

- Open electrical cabinet

- Find motor drive or contactor

- Identify three phase wires (L1, L2, L3)

Step 3: Install CT

- Clamp CT around ONE phase wire only (any of the three)

- Arrow on CT should point toward motor

- Secure CT so it doesn't vibrate loose

- Do not clamp around multiple wires

- Do not clamp around insulated cable bundle (individual wire only)

Step 4: Wire CT Output

- Analog CT: Connect to AN1 and AG terminals

- Dry Contact CT: Connect through external 24VDC to Opto 1

Signal Selection Strategy

Utilization Signals

Goal: Determine if machine is ACTIVE or IDLE.

Preferred Methods (in order):

- Current Transducer on Spindle (Most Reliable)

- Analog CT: Monitors actual motor current

- Set low threshold (1.0-1.5V) for low-speed detection

- Works on almost any spindle-driven equipment

- Green Stack Light (If Accurate)

- Wet contact: 24VDC when machine running

- Simple and reliable

- Verify it accurately reflects in-cycle state

- PLC Output "In Cycle" (If Available)

- Dedicated signal from PLC

- Most accurate when available

- May be labeled "Auto Mode", "Cycle Active", etc.

Part Count Signals

Goal: Detect when a part has been completed.

Preferred Methods (in order):

- Part Count Relay (Ideal)

- Dedicated relay triggered by M-code in program

- Pulses briefly after each part

- Most reliable method

- Pallet Changer Signal (Mills with Pallets)

- Signal when pallet changes

- Each pallet change = parts completed

- Monitor "Pallet Index Complete" or similar

- Barfeeder Pulse (Lathes with Barfeeders)

- Signal when barfeeder advances

- Each advance = new part started

- May need logic: count on part eject, not bar advance

- Part Ejector/Unloader

- Signal from part handling equipment

- Part catcher, conveyor, or robot

- May need combination logic (ejector AND auto mode)

- Coolant Pump Pulse (Last Resort)

- ⚠️ Use only when other methods not available

- Requires two M-code pulses (on, off, on, off)

- Must use min-delta and max-delta for timing verification

- Can cause excessive coolant pump wear

- Requires program modifications

Sealevel eI/O-170 Installation

Physical Installation

Step 1: Mount Module

- Install on 35mm DIN rail in electrical cabinet

- Keep away from high-voltage lines (>240VAC)

- Accessible location for wiring

- Protected from coolant and chips

Step 2: Power Connection

Standard Model (eI/O-170E):

24VDC (+) → V+ terminal (side of module)

24VDC (-) → V- terminal

PoE Model (eI/O-170PoE):

- Connect CAT5/CAT6 ethernet cable

- PoE provides power automatically via ethernet

Step 3: Network Connection

- Connect ethernet cable to RJ45 port

- Connect to network switch

- Module communicates with Edge device over network

Network Configuration

Sealevel I/O Module with terminal connections - The module features multiple digital input and output terminals for wiring machine signals. Note the clear terminal labeling and the RJ45 Ethernet port for network connectivity. This view shows the actual connection points where you'll wire current transducers, part count signals, and other machine I/O.

Step 1: Download SeaMAX Software

- Visit: https://www.sealevel.com/software-seamax-windows

- Download SeaMAX Suite for Windows

- Install as administrator

Step 2: Discover Module

- Launch "Ethernet Config" utility (Start → All Programs → Sealevel Systems → SeaMAX → Ethernet Configuration Tool)

- Click "Search for SeaI/O Devices"

- Modules on network will appear

- Default IP: 192.168.42.253

Step 3: Configure Static IP

- Select module in device list

- Enter new static IP address (from your IT team)

- Example: 192.168.1.101

- Enter subnet mask: 255.255.255.0

- Enter gateway (if required)

- Click "Apply Changes"

- Module will reboot with new IP

Step 4: Verify Connection

- Ping module from Edge device or computer

- Launch MaxSSD utility (Start → All Programs → Sealevel Systems → SeaMAX → MaxSSD Configuration Utility)

- Select "Ethernet" from COM Port dropdown

- Select module IP from list

- Click "Get SeaIO Module Settings"

- Module information should display

Terminal Wiring

Analog Inputs (for CTs):

AN1 - Analog Input 1 (address 0, e.g., main spindle CT)

AN2 - Analog Input 2 (address 1, e.g., live tooling CT)

AN3 - Analog Input 3 (address 2, e.g., Z-axis CT)

AN4 - Analog Input 4 (address 3)

AN5 - Analog Input 5 (address 4)

AN6 - Analog Input 6 (address 5)

AN7 - Analog Input 7 (address 6)

AN8 - Analog Input 8 (address 7)

AG - Analog Ground (common for all analog inputs)

Digital Inputs (Opto 1 & Opto 2):

Opto 1 - Digital Input 0 (dry contact sensing)

Opto 2 - Digital Input 1 (dry contact sensing)

COM - Common for digital inputs

⚠️ CRITICAL: Digital inputs are internally powered (source 12mA). Connect switch/relay contacts between Opto terminal and COM. DO NOT apply external voltage to these inputs.

Example: Dry Contact Relay Wiring to Opto 1:

External 24VDC (+) → One side of relay N.O. contact

Other side of relay contact → Opto 1 terminal

COM terminal → External 24VDC (-)

WISE-4050 Installation & Configuration

Advantech WISE-4050/LAN Ethernet I/O Module - A versatile wireless/wired I/O module with multiple digital inputs and outputs. This compact module supports both WiFi (WISE-4050) and Ethernet (WISE-4050/LAN) connectivity, making it ideal for machines where running cables is difficult. The module communicates via Modbus TCP and features indicator LEDs for easy status monitoring. Image shows the wired LAN version.

Physical Installation

Step 1: Mount Module

- Snap onto 35mm DIN rail

- Mount inside electrical cabinet for protection

Step 2: Antenna Mounting (Wireless WISE-4050 Only)

IMPORTANT: For wireless WISE-4050 modules, the antenna must be mounted externally to the electrical cabinet for proper WiFi signal reception.

WiFi antenna extension cable with RP-SMA connector - Required for wireless WISE-4050 installations. The extension cable connects the WISE-4050 module inside the electrical cabinet to the antenna mounted outside the cabinet. The cable features spring-coiled sections for flexibility and a magnetic base antenna for easy external mounting.

Antenna Installation Requirements:

-

Drill Hole in Cabinet

- A hole must be drilled in the electrical cabinet wall

- Size: Appropriate for antenna connector/cable (typically 1/2" to 3/4")

- Location: Choose a location with clear line-of-sight to WiFi access points

- Coordinate with machine owner/electrician before drilling

-

Antenna Extension Cable Required

- Customer must purchase an antenna extension cable

- Cable connects WISE-4050 module (inside cabinet) to antenna (outside cabinet)

- Cable type: RP-SMA or compatible with WISE-4050 antenna connector

- Recommended length: 1-3 feet (minimize signal loss)

- Features: Magnetic base antenna for easy mounting

-

Mount Antenna Externally

- Route extension cable through drilled hole

- Attach antenna to outside of cabinet (magnetic base works well on metal cabinets)

- Secure antenna in position with appropriate mounting hardware

- Ensure antenna has clear path for WiFi signals

Note: The WISE-4050/LAN (wired Ethernet version) does not require antenna mounting. Simply connect an Ethernet cable to the module's RJ45 port.

Step 3: Power Connection

24VDC (+) → V+ terminal

24VDC (-) → V- terminal

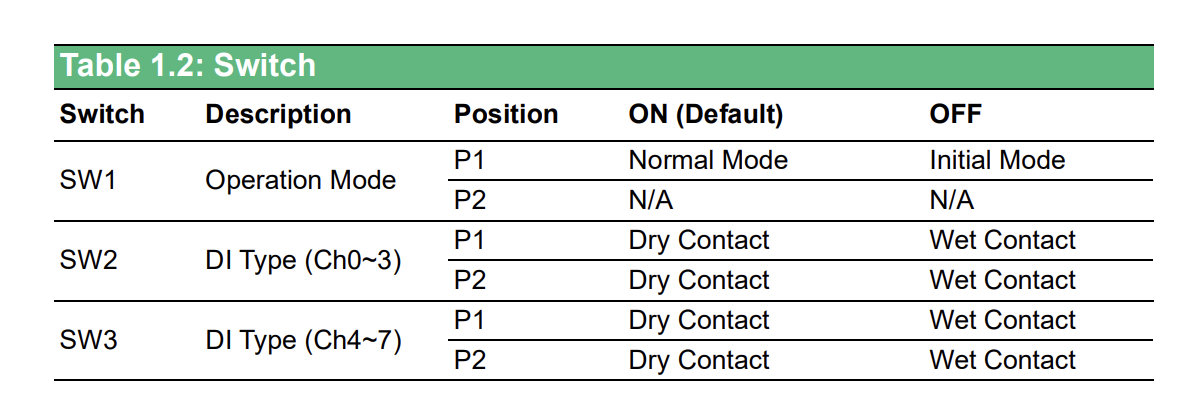

DIP Switch Configuration

Before wiring signals to the WISE-4050, you must configure the DIP switches on the back of the module to set the input type (wet contact or dry contact) for each digital input channel.

WISE-4050 DIP Switch Configuration - The module has three switches (SW1, SW2, SW3) on the back that control operation mode and input types. SW2 configures channels DI0-3, and SW3 configures channels DI4-7. Set to ON for dry contact or OFF for wet contact.

DIP Switch Functions:

| Switch | Description | Position | ON (Default) | OFF |

|---|---|---|---|---|

| SW1 | Operation Mode | P1 | Normal Mode | Initial Mode |

| P2 | N/A | N/A | ||

| SW2 | DI Type (Ch0-3) | P1 | Dry Contact | Wet Contact |

| P2 | Dry Contact | Wet Contact | ||

| SW3 | DI Type (Ch4-7) | P1 | Dry Contact | Wet Contact |

| P2 | Dry Contact | Wet Contact |

Understanding Contact Types:

Wet Contact (Switch OFF)

- Machine provides voltage on the signal wire

- Example: Machine outputs 24VDC when signal is active

- Common for: Stack lights, relay outputs, PLC outputs with power

- Wiring: Connect signal wire to DI terminal, no external power needed

Dry Contact (Switch ON - Default)

- Machine provides contact closure only (no voltage)

- Requires external power supply

- Common for: Relay contacts, switch contacts, mechanical contacts

- Wiring: Connect external 24VDC (+) to one side of contact, other side to DI terminal

Configuration Examples:

Example 1: All Wet Contacts (Stack Lights)

- Machine outputs 24VDC on all signals

- Set SW2 P1, P2 = OFF (channels DI0-3)

- Set SW3 P1, P2 = OFF (channels DI4-7)

Example 2: All Dry Contacts (Relay Contacts)

- Machine has relay contacts only

- Set SW2 P1, P2 = ON (channels DI0-3) - Default

- Set SW3 P1, P2 = ON (channels DI4-7) - Default

- Provide external 24VDC power

Example 3: Mixed Configuration

- DI0-3: Wet contacts (stack lights)

- DI4-7: Dry contacts (relay contacts)

- Set SW2 P1, P2 = OFF (wet contact for DI0-3)

- Set SW3 P1, P2 = ON (dry contact for DI4-7)

Important Notes:

⚠️ POWER OFF the WISE-4050 before changing DIP switch settings. Changing switches while powered can damage the module.

⚠️ MATCH SIGNAL TYPE to switch setting. Applying 24VDC to an input configured for dry contact can damage the module.

Step 4: Wire Signal Connections

After configuring DIP switches, wire your machine signals according to the contact type selected.

WiFi Configuration (Wireless Model)

Initial Setup - Connect to WISE AP:

- Power on WISE-4050

- Module creates its own WiFi network on first boot

- SSID:

WISE-4050-XXXXXX(last 6 digits of MAC address) - No password required initially

- Connect Computer to WISE WiFi

- Use laptop or tablet

- Connect to WISE-4050-XXXXXX WiFi network

- Computer will receive IP via DHCP

- Access Web Interface

- Open web browser

- Navigate to:

http://10.0.0.1 - Login:

root - Password:

00000000(8 zeros)

[Recommended Image]: Screenshot of WISE-4050 web interface login and configuration page

Configure for Your Shop WiFi (Infrastructure Mode):

- Change to Infrastructure Mode

- In web interface, go to: Network → WLAN → Mode

- Select: Infrastructure

- Click Submit

- Select Your WiFi Network

- Go to: Network → WLAN → Infrastructure Settings

- SSID: Enter your shop WiFi network name

- Security: Select security type (WPA2-PSK recommended)

- Password: Enter your WiFi password

- Click Submit

- Configure Static IP (Recommended)

- Go to: Network → LAN → Ethernet/WLAN IP Configuration

- Uncheck Enable DHCP

- IP Address: Enter static IP (from IT team)

- Example: 192.168.1.150

- Subnet Mask: 255.255.255.0

- Gateway: Your network gateway

- Click Submit

- Set Modbus Unit ID

- Go to: I/O Status → Modbus Address

- Unit ID: Set to

1(or as required) - Click Submit

- Reboot Module

- Go to: Maintenance → System → Reboot

- Click Reboot

- Module will restart and connect to your WiFi

- Verify Connection

- Reconnect computer to your shop WiFi

- Navigate to new IP address:

http://192.168.1.150(your configured IP) - Should see WISE web interface

- Verify WiFi signal strength in web interface

Important Security Settings:

- Change Default Password

- Go to: Maintenance → Account

- Change password from default

00000000 - Use strong password

- Document password for future access

WISE-4050/LAN Configuration (Wired Model)

- Connect ethernet cable to RJ45 port

- Access web interface at default IP:

http://10.0.0.1 - Login: root / 00000000

- Configure static IP as described above

- Set Modbus Unit ID to 1

Terminal Wiring Examples

IMPORTANT: Ensure DIP switches are configured correctly BEFORE wiring signals. See DIP Switch Configuration section above.

Wet Contact Wiring (DIP Switch OFF)

Use when machine provides voltage on signal wire (e.g., stack lights, PLC outputs with power):

Green Light (+24VDC) → DI0+ terminal

Green Light (0V/GND) → COM terminal

Yellow Light (+24VDC) → DI1+ terminal

Yellow Light (0V/GND) → COM terminal

Part Signal (+24VDC) → DI2+ terminal

Part Signal (0V/GND) → COM terminal

DIP Switch Setting: SW2 OFF (for DI0-3)

Dry Contact Wiring (DIP Switch ON - Default)

Use when machine provides contact closure only (e.g., relay contacts, mechanical switches):

External 24VDC (+) → DI0+ terminal

Relay Contact (NO) → DI0- terminal

Relay Contact (COM) → COM terminal

External 24VDC (+) → DI1+ terminal

Switch Contact → DI1- terminal

Switch Contact → COM terminal

DIP Switch Setting: SW2 ON (for DI0-3) - This is the default setting

Mixed Contact Example

DI0-3 configured for wet contacts (stack lights):

DIP Switch SW2: OFF

Green Light (24VDC) → DI0+

Yellow Light (24VDC) → DI1+

Red Light (24VDC) → DI2+

All grounds → COM

DI4-7 configured for dry contacts (relay):

DIP Switch SW3: ON (default)

External 24VDC (+) → DI4+

Relay contact → Between DI4- and COM

WISE High-Frequency Counter Mode (Advanced)

For applications requiring RPM tracking or high-frequency pulse counting (e.g., conveyor speed, encoder pulses, production counters), we recommend using a WISE unit (either wireless or wired) configured in counter mode.

When to Use Counter Mode

Common use cases:

- RPM monitoring: Spindle speed from encoder pulses

- Conveyor speed: Tracking belt or chain speed from proximity sensors

- High-speed part counting: Fast production lines with high pulse rates

- Encoder tracking: Position or speed from rotary encoders

- Frequency measurement: Any signal above 10 Hz

Why WISE for High-Frequency?

- Standard digital inputs sample too slowly for fast pulses

- Counter mode accumulates pulses in hardware (no missed counts)

- Can handle frequencies up to several kHz

- Polling adapter reads total count, not individual pulses

Configuring WISE Input as Counter

Step 1: Access WISE Web Interface

- Navigate to WISE IP address in browser:

http://192.168.1.150(your configured IP) - Login:

root/ your password - Go to: I/O Status → Digital Input Configuration

Step 2: Set Input Mode to Counter

- Select the input channel (DI0, DI1, DI2, or DI3)

- Mode: Change from "Digital Input" to "Counter"

- Counter Type: Select "Frequency Counter" or "Pulse Counter"

- Click Submit and Reboot the module

Note: Once an input is set to counter mode, it accumulates pulses continuously. The adapter script reads the current count value and calculates the difference since the last reading.

How Counter Mode Works

Normal Digital Input Mode:

- Adapter reads:

trueorfalse(on/off state) - High-speed pulses may be missed between reads

- Limited to ~10 Hz sampling frequency

Counter Mode:

- Adapter reads: Current accumulated count (integer)

- WISE hardware counts every pulse (no missed counts)

- Adapter calculates:

count_difference = current_count - previous_count - Supports frequencies up to several kHz

Polling Frequency:

- Use

resampleparameter in variables for precise sampling control - For RPM:

resample: 5(5-second sampling) is usually sufficient - For real-time counting: Use

resample: 0.5orresample: 1(500ms or 1-second sampling) - More accurate and reliable than global

scan-interval

Recommended: Place

resamplein the variable pipeline (e.g., aftervalue-increase-diff) for best results.

WISE Counter Register Addresses

When using counter mode, WISE modules expose counter values as Modbus holding registers:

| Digital Input | Counter Register Address | Function Code | Type |

|---|---|---|---|

| DI0 | 40019 | 3 (Read Holding Registers) | int16 |

| DI1 | 40020 | 3 | int16 |

| DI2 | 40021 | 3 | int16 |

| DI3 | 40022 | 3 | int16 |

Important: Counter mode changes the input from a boolean coil to a 16-bit register. The digital input coil remains available separately for reading the current state.

Sample Script: RPM Calculation from Encoder

Hardware Setup:

- WISE-4050 or WISE-4050/LAN

- DI0: Encoder pulse output (configured as counter in WISE web interface)

- Encoder: 60 pulses per revolution (PPR)

- Resample interval: 5 seconds

Configuration:

version: 2

unit-id: 1

registers:

encoder-count:

address: 40019 # DI0 counter register

type: int16

variables:

# Track count increase (pulses since last reading)

pulse-diff:

- source: encoder-count

- value-increase-diff # Returns difference from last reading

- resample: 5 # Sample counter every 5 seconds

# Calculate RPM from pulse difference

# Formula: RPM = (pulses / PPR) * (60 / resample_interval)

# With 60 PPR and 5-second resample: RPM = (pulses / 60) * (60 / 5)

# Simplified: RPM = pulses / 5

spindle-rpm:

- source: pulse-diff / 5

- expression: round(this, 0) # Round to whole number

# Optional: Execution state from RPM

execution:

- source: spindle-rpm > 100 # Active if RPM > 100

- state:

- ACTIVE: this

- READY: true

data-items:

- spindle-rpm

- encoder-count

- execution

Key Points:

resample: 5in the variable pipeline samples the counter value every 5 seconds- More accurate and reliable than using

scan-interval value-increase-diffreturns the count increase since last reading- RPM formula depends on PPR (pulses per revolution) and resample interval

encoder-countis cumulative and will roll over at max int16 (32,767)- Roll-over is handled automatically by

value-increase-diff - Register address 40019 is for DI0 counter

Note: The

resampleparameter goes in the variables section, not on the register definition.

Sample Script: High-Speed Part Counting

Hardware Setup:

- WISE-4050

- DI1: Part sensor configured as counter in WISE web interface

- Part sensor pulses once per part

- Resample interval: 1 second

Configuration:

version: 2

unit-id: 1

registers:

parts-counter:

address: 40020 # DI1 counter register

type: int16

variables:

# Extract count difference and accumulate

part-count:

- source: parts-counter

- value-increase-diff # Get new parts since last poll

- resample: 1 # Sample counter every 1 second

- count # Accumulate into total

# Calculate parts per minute (production rate)

parts-per-minute:

- source: parts-counter

- value-increase-diff

- resample: 1 # Sample counter every 1 second

- expression: this * 60 # Scale 1-second reading to per-minute

# Execution based on production activity

execution:

- source: parts-per-minute > 5 # Active if producing

- off-delay: 30 # Hold for 30 seconds

- state:

- ACTIVE: this

- READY: true

data-items:

- part-count

- parts-per-minute

- parts-counter

- execution

Key Points:

- Counter mode ensures no pulses are missed on fast production lines

resample: 1in the variable pipeline samples the counter value every 1 second- More accurate and reliable than using

scan-interval value-increase-diffgets new parts since last readingcountoperation accumulates differences into running total- Scale to per-minute by multiplying by

60 / resample_interval - Register address 40020 is for DI1 counter

- Counter will roll over at 32,767 (handled automatically)

Note: The

resampleparameter goes in the variables section, not on the register definition.

RPM Calculation Reference

General RPM Formula:

RPM = (pulses_per_scan / pulses_per_revolution) * (60 / scan_interval_seconds)

Example Calculations:

| PPR | Scan Interval | Pulses Counted | RPM Calculation |

|---|---|---|---|

| 60 | 5 seconds | 300 | (300/60) * (60/5) = 60 RPM |

| 1 | 5 seconds | 50 | (50/1) * (60/5) = 600 RPM |

| 100 | 1 second | 50 | (50/100) * (60/1) = 30 RPM |

| 360 | 5 seconds | 1800 | (1800/360) * (60/5) = 60 RPM |

Simplified Formulas for Common Configurations:

# 60 PPR, 5-second resample:

pulse-diff:

- source: encoder-count

- value-increase-diff

- resample: 5

spindle-rpm:

- source: pulse-diff / 5

# 1 PPR (1 pulse per revolution), 5-second resample:

pulse-diff:

- source: encoder-count

- value-increase-diff

- resample: 5

spindle-rpm:

- source: pulse-diff * 12

# 100 PPR, 1-second resample:

pulse-diff:

- source: encoder-count

- value-increase-diff

- resample: 1

spindle-rpm:

- source: pulse-diff * 0.6

# 360 PPR, 5-second resample:

pulse-diff:

- source: encoder-count

- value-increase-diff

- resample: 5

spindle-rpm:

- source: pulse-diff / 30

Complete Working Example: WISE High-Frequency Counter

This is a real-world configuration using a WISE unit with DI0 configured as a counter.

Hardware Setup:

- WISE-4050 or WISE-4050/LAN

- DI0: High-frequency pulse input (configured as counter in WISE web interface)

- DI0 also used for execution state detection

Basic Counter Configuration:

version: 2

unit-id: 1

coils:

di0:

address: 1 # Digital input state (still available)

registers:

counter1:

address: 40019 # DI0 counter register

type: int16 # 16-bit signed integer

variables:

execution:

- source: di0 # Use digital input state

- resample: 0.1 # Sample every 100ms for fast response

- state:

- ACTIVE: this

- INTERRUPTED: true

data-items:

- di0 # Current input state

- execution # Derived state

- counter1 # Counter value

With RPM Calculation:

version: 2

unit-id: 1

coils:

di0:

address: 1

registers:

counter1:

address: 40019

type: int16

variables:

# Calculate pulses since last reading

pulse-diff:

- source: counter1

- value-increase-diff

- resample: 5 # Sample counter every 5 seconds

# Calculate RPM (assuming 60 pulses per revolution)

# Formula: (pulses / 60 PPR) * (60 seconds / 5 second resample)

# Simplified: pulses / 5

spindle-rpm:

- source: pulse-diff / 5

- expression: round(this, 0)

# Execution from RPM threshold

execution:

- source: spindle-rpm > 100

- state:

- ACTIVE: this

- READY: true

data-items:

- di0

- execution

- counter1

- spindle-rpm

Key Points:

- Counter register is at address 40019 for DI0

- Counter is int16 type (range: -32,768 to 32,767)

- Digital input coil remains available at address 1

resamplein variables controls sampling frequency for each data point- Both the counter value and input state are output

Note: The

resampleparameter goes in the variables section, not on registers or at the global level.

Counter Roll-Over Handling

Since the counter is int16, it will roll over at:

- Maximum: 32,767

- Rolls to: -32,768

The value-increase-diff operation handles this roll-over automatically, so your counts remain accurate even after roll-over occurs.

Troubleshooting Counter Mode

Counter not incrementing:

- Verify input is configured as counter in WISE web interface

- Check signal wiring and voltage (should be 10-50VDC for wet contact)

- Test signal with multimeter or oscilloscope

- Ensure signal frequency is within WISE specifications

Incorrect RPM or count:

- Verify PPR (pulses per revolution) for your encoder

- Check scan interval matches script configuration

- Confirm register address matches DI channel

- Test with known RPM source for calibration

Counter resets unexpectedly:

- Check WISE power supply stability

- Verify network connectivity (dropped connections can cause resets)

- Review WISE system logs in web interface

Modbus TCP Addressing

Sealevel eI/O-170 Address Map

Analog Inputs:

- AN1 → Register 0 (function 4, type int16)

- AN2 → Register 1 (function 4, type int16)

- AN3 → Register 2 (function 4, type int16)

- AN4 → Register 3 (function 4, type int16)

- AN5 → Register 4 (function 4, type int16)

- AN6 → Register 5 (function 4, type int16)

- AN7 → Register 6 (function 4, type int16)

- AN8 → Register 7 (function 4, type int16)

Digital Inputs (Opto 1 & Opto 2):

- Opto 1 → Coil 0 (function 2 - Read Discrete Inputs)

- Opto 2 → Coil 1 (function 2 - Read Discrete Inputs)

WISE-4050 Address Map

Digital Inputs:

- DI0 → Coil 0 (function 2 - Read Discrete Inputs)

- DI1 → Coil 1 (function 2 - Read Discrete Inputs)

- DI2 → Coil 2 (function 2 - Read Discrete Inputs)

- DI3 → Coil 3 (function 2 - Read Discrete Inputs)

Data Types

Sealevel eI/O-170:

- Analog Inputs:

int16(0-4095 raw counts) - Digital Inputs: Boolean (coils)

WISE-4050:

- Digital Inputs: Boolean (coils)

Comprehensive Adapter Script Examples

Reference Documentation:

- Adapter Scripts Guide: https://developers.machinemetrics.com/docs/adapter-scripts/intro

- Available Operations: https://developers.machinemetrics.com/docs/adapter-scripts/operations

Example 1: CT for Execution (Main Spindle)

Hardware: Sealevel eI/O-170E

- AN1: Main spindle CT (analog 0-10V model)

Configuration:

version: 2

unit-id: 1

registers:

spindle-raw:

address: 0 # AN1

func: 4 # Read Input Registers

type: int16 # Raw ADC counts (0-4095)

variables:

# Convert raw ADC counts to voltage (0-10V range)

# 4096 counts = 10V, so divide by 409.6 to get voltage

ct-voltage-int:

- source: spindle-raw / 409.6 # Intermediate voltage (0.0 to 10.0 VDC)

# Create cleaned version for data output (reduces noise/database load)

ct-voltage:

- source: ct-voltage-int

- resample: 0.5 # Sample every 500ms

- min-delta: 0.1 # Only report changes >0.1V

# Execution based on voltage threshold with off-delay

execution:

- source: ct-voltage-int > 1.15 # 1.15V threshold

- off-delay: 10 # 10 second off-delay (prevents flicker)

- state:

- ACTIVE: this

- READY: true

data-items:

- execution

- ct-voltage # Send cleaned voltage value for trending

Key Points:

- Raw ADC is 0-4095 (12-bit)

- Divide by 409.6 to convert to 0-10V

- Create intermediate variable (

ct-voltage-int) for threshold logic - Create cleaned variable (

ct-voltage) with resample and min-delta for data output - Use cleaned version in

data-itemsto reduce database load - 1.15V threshold catches low-speed operations

- 10-second off-delay prevents flicker during rapid start/stop

Example 2: Multiple CTs (Main Spindle + Live Tooling + Z-Axis)

Hardware: Sealevel eI/O-170E

- AN1: Main spindle CT

- AN2: Live tooling head CT

- AN3: Z-axis drive CT

- Opto 1: Part eject signal (dry contact)

Configuration:

version: 2

unit-id: 1

registers:

main-spindle-raw:

address: 0 # AN1

func: 4

type: int16

live-tool-raw:

address: 1 # AN2

func: 4

type: int16

z-axis-raw:

address: 2 # AN3

func: 4

type: int16

coils:

part-eject:

address: 0 # Opto 1

func: 2 # Read Discrete Inputs

variables:

# Convert all CTs to voltage (intermediate)

main-spindle-voltage-int:

- source: main-spindle-raw / 409.6

live-tool-voltage-int:

- source: live-tool-raw / 409.6

z-axis-voltage-int:

- source: z-axis-raw / 409.6

# Create cleaned versions for data output

main-spindle-voltage:

- source: main-spindle-voltage-int

- resample: 0.5

- min-delta: 0.1

live-tool-voltage:

- source: live-tool-voltage-int

- resample: 0.5

- min-delta: 0.1

z-axis-voltage:

- source: z-axis-voltage-int

- resample: 0.5

- min-delta: 0.1

# Machine active if ANY spindle/axis has current

execution:

- source: main-spindle-voltage-int > 1.0 or live-tool-voltage-int > 1.0 or z-axis-voltage-int > 0.8

- off-delay: 10

- state:

- ACTIVE: this

- READY: true

# Part count on eject signal

part-count:

- source: part-eject

- rising-edge

- count

data-items:

- execution

- part-count

- main-spindle-voltage

- live-tool-voltage

- z-axis-voltage

Key Points:

- Monitors three different motors/drives

- Uses OR logic: active if any has current

- Lower threshold for Z-axis (0.8V) as it draws less current

- Intermediate variables (

-intsuffix) for threshold logic - Cleaned variables with resample/min-delta for data output

- Separate voltage values for analysis/trending

Example 3: Stack Lights + Dry Contact Part Count

Hardware: WISE-4050

- DI0: Green light (24VDC wet contact)

- DI1: Yellow light (24VDC wet contact)

- DI2: Part count relay (dry contact with external 24VDC)

- DI3: Red light (24VDC wet contact)

Machine Behavior:

- Green ON + Yellow OFF = In cycle (ACTIVE)

- Green ON + Yellow ON = Operator stop (INTERRUPTED)

- Red ON = Alarm (INTERRUPTED)

- All OFF = Idle (READY)

Configuration:

version: 2

unit-id: 1

coils:

green-light:

address: 0 # DI0

func: 2 # Read Discrete Inputs

yellow-light:

address: 1 # DI1

func: 2

part-relay:

address: 2 # DI2

func: 2

red-light:

address: 3 # DI3

func: 2

variables:

# Complex execution state from light combination

execution:

- state:

- INTERRUPTED: red-light # Alarm

- INTERRUPTED: green-light and yellow-light # Op-stop

- ACTIVE: green-light and yellow-light == false # In cycle

- READY: true # Idle

# Part counter

part-count:

- source: part-relay

- rising-edge

- count

data-items:

- execution

- part-count

- green-light

- yellow-light

- red-light

Key Points:

- Order matters in

state:(first match wins) - Check alarm and op-stop before checking active

- Use

== falseinstead ofnotfor clarity - Send individual light states for diagnostics

Example 4: Pallet Changer on Mill

Hardware: WISE-4050

- DI0: Pallet index complete signal

- DI1: Auto mode signal

- DI2: Spindle running (from CT with dry contact output)

Configuration:

version: 2

unit-id: 1

coils:

pallet-index:

address: 0 # DI0

func: 2 # Read Discrete Inputs

auto-mode:

address: 1 # DI1

func: 2

spindle:

address: 2 # DI2

func: 2

variables:

# Active when spindle running

execution:

- source: spindle

- off-delay: 10

- state:

- ACTIVE: this

- READY: true

# Count parts on pallet change (only in auto mode)

part-count:

- source: pallet-index and auto-mode # Both must be true

- rising-edge

- count

data-items:

- execution

- part-count

- auto-mode

Key Points:

- Use

andoperator for combination logic - Pallet index only counts in auto mode

- Prevents false counts during manual pallet changes

Example 5: Barfeeder Pulse on Lathe

Hardware: Sealevel eI/O-170E

- AN1: Main spindle CT

- Opto 1: Barfeeder advance complete signal

Configuration:

version: 2

unit-id: 1

registers:

spindle-raw:

address: 0 # AN1

func: 4

type: int16

coils:

barfeed-pulse:

address: 0 # Opto 1

func: 2 # Read Discrete Inputs

variables:

# Spindle monitoring (intermediate conversion)

spindle-voltage-int:

- source: spindle-raw / 409.6

# Cleaned version for data output

spindle-voltage:

- source: spindle-voltage-int

- resample: 0.5

- min-delta: 0.1

execution:

- source: spindle-voltage-int > 1.0

- off-delay: 10

- state:

- ACTIVE: this

- READY: true

# Count on barfeed advance (new part started)

part-count:

- source: barfeed-pulse

- rising-edge

- count

data-items:

- execution

- part-count

- spindle-voltage

Key Points:

- Barfeed advance indicates new part cycle starting

- Each bar advance = 1 part (adjust if multiple parts per bar)

- May need to count on part eject instead depending on machine

Example 6: Coolant Pulse Method (Last Resort)

Hardware: Sealevel eI/O-170E

- AN1: Spindle CT

- Opto 1: Coolant pump contactor (dry contact)

⚠️ WARNING: Use this method only when other part counting methods are not available. Requires program modifications and uses 2 pulses.

M-Code in Part Program:

M08 ; Coolant ON (pulse 1)

G04 P0.5 ; Wait 0.5 seconds

M09 ; Coolant OFF

G04 P0.5 ; Wait 0.5 seconds

M08 ; Coolant ON (pulse 2)

G04 P0.5 ; Wait 0.5 seconds

M09 ; Coolant OFF

M30 ; Program end

Configuration:

version: 2

unit-id: 1

registers:

spindle-raw:

address: 0 # AN1

func: 4

type: int16

coils:

coolant-raw:

address: 0 # Opto 1

func: 2 # Read Discrete Inputs

variables:

# Spindle monitoring (intermediate conversion)

spindle-voltage-int:

- source: spindle-raw / 409.6

# Cleaned version for data output

spindle-voltage:

- source: spindle-voltage-int

- resample: 0.5

- min-delta: 0.1

execution:

- source: spindle-voltage-int > 1.0

- off-delay: 10

- state:

- ACTIVE: this

- READY: true

# Filter coolant signal to verify pulse duration

coolant-filtered:

- source: coolant-raw

- min-delta: 0.4 # Must be on for at least 0.4 seconds

- max-delta: 0.7 # Must be on for no more than 0.7 seconds

# Count on filtered coolant signal (2 pulses = 1 part)

pulse-count:

- source: coolant-filtered

- rising-edge

- count

# Divide pulse count by 2 to get part count

part-count:

- source: pulse-count / 2

data-items:

- execution

- part-count

- spindle-voltage

Key Points:

min-deltaandmax-deltaverify pulse duration (0.4-0.7 sec)- Prevents false counts from normal coolant operation

- Two pulses required per part (divide count by 2)

- Adds wear to coolant pump (use sparingly)

- Requires modification of all part programs

Example 7: Auto Mode Filtering

Hardware: WISE-4050

- DI0: Auto mode signal

- DI1: Part ejector signal

- DI2: Green light

Problem: Part ejector can be triggered manually during setup. Only count parts in auto mode.

Configuration:

version: 2

unit-id: 1

coils:

auto-mode:

address: 0 # DI0

func: 2 # Read Discrete Inputs

part-ejector:

address: 1 # DI1

func: 2

green-light:

address: 2 # DI2

func: 2

variables:

# Execution from green light

execution:

- source: green-light

- state:

- ACTIVE: this

- READY: true

# Part count ONLY when in auto mode (using AND logic)

part-count:

- source: part-ejector and auto-mode # Both must be true

- rising-edge

- count

data-items:

- execution

- part-count

- auto-mode

Key Points:

- Use

andoperator to combine conditions - Prevents false counts during manual operation

- Common requirement for automated equipment

Example 8: Injection Molding Machine

Hardware: WISE-4050

- DI0: Mold closed (wet contact)

- DI1: Auto mode (wet contact)

- DI2: Injection in progress

- DI3: Alarm

Configuration:

version: 2

unit-id: 1

coils:

mold-closed:

address: 0

func: 2 # Read Discrete Inputs

auto-mode:

address: 1

func: 2

injection:

address: 2

func: 2

alarm:

address: 3

func: 2

variables:

# Execution state

execution:

- state:

- INTERRUPTED: alarm

- ACTIVE: injection and auto-mode

- READY: true

# Count parts on mold closing (only in auto)

part-count:

- source: mold-closed and auto-mode # Both must be true

- rising-edge

- count

data-items:

- execution

- part-count

- auto-mode

- alarm

Machine-Specific Integrations

Haas CNC Machines (Pre 2001)

Recommended Configuration:

- Hardware: Sealevel eI/O-170E

- AN1: Spindle CT (analog 0-10V)

- Opto 1: Part count relay or coolant contactor

Adapter Script:

version: 2

unit-id: 1

registers:

spindle-raw:

address: 0 # AN1

func: 4

type: int16

coils:

part-signal:

address: 0

func: 2 # Read Discrete Inputs

variables:

# Spindle monitoring (intermediate conversion)

spindle-voltage-int:

- source: spindle-raw / 409.6

# Cleaned version for data output

spindle-voltage:

- source: spindle-voltage-int

- resample: 0.5

- min-delta: 0.1

execution:

- source: spindle-voltage-int > 1.15

- off-delay: 10

- state:

- ACTIVE: this

- READY: true

part-count:

- source: part-signal

- rising-edge

- count

data-items:

- execution

- part-count

- spindle-voltage

Citizen/Miyano Lathes

Recommended Configuration:

- Hardware: Sealevel eI/O-170E

- AN1: Main spindle CT

- AN2: Sub spindle CT (if applicable)

- Opto 1: Work count relay

Adapter Script:

version: 2

unit-id: 1

registers:

main-spindle-raw:

address: 0 # AN1

func: 4

type: int16

sub-spindle-raw:

address: 1 # AN2

func: 4

type: int16

coils:

work-count:

address: 0

func: 2 # Read Discrete Inputs

variables:

# Convert CTs to voltage (intermediate)

main-voltage-int:

- source: main-spindle-raw / 409.6

sub-voltage-int:

- source: sub-spindle-raw / 409.6

# Cleaned versions for data output

main-voltage:

- source: main-voltage-int

- resample: 0.5

- min-delta: 0.1

sub-voltage:

- source: sub-voltage-int

- resample: 0.5

- min-delta: 0.1

# Active if either spindle running

execution:

- source: main-voltage-int > 1.0 or sub-voltage-int > 1.0

- off-delay: 10

- state:

- ACTIVE: this

- READY: true

part-count:

- source: work-count

- rising-edge

- count

data-items:

- execution

- part-count

- main-voltage

- sub-voltage

Troubleshooting

Cannot Connect to Module

Diagnostic Steps:

- Check Power

- Sealevel: Power LED green?

- WISE: Power LED on?

- Measure voltage at terminals: 24VDC ±10%

- Check Network

- Cable fully seated in RJ45?

- Link lights blinking?

- Try different cable or switch port

- Check IP Address

- Sealevel default: 192.168.42.253

- WISE default: 10.0.0.1 or DHCP

- Is computer on same subnet?

- Ping Module

- Open command prompt

ping 192.168.42.253(or module IP)- Should receive replies

Signal Not Detected

Diagnostic Steps:

- Measure Voltage

- Use multimeter

- Measure between input terminal and common

- Should read signal voltage when active

- Should read near 0V when inactive

- Check Wiring

- Terminals tight?

- Correct polarity?

- Any broken wires?

- Verify Modbus Address

- Sealevel: AI0=register 0, Opto 1=coil 0

- WISE: DI0=coil 0, DI1=coil 1, etc.

- Test with Configuration Tool

- Sealevel: Use MaxSSD utility

- WISE: Use web interface diagnostics

- Confirm signal reaches module

Current Transducer (CT) State Detection Issues

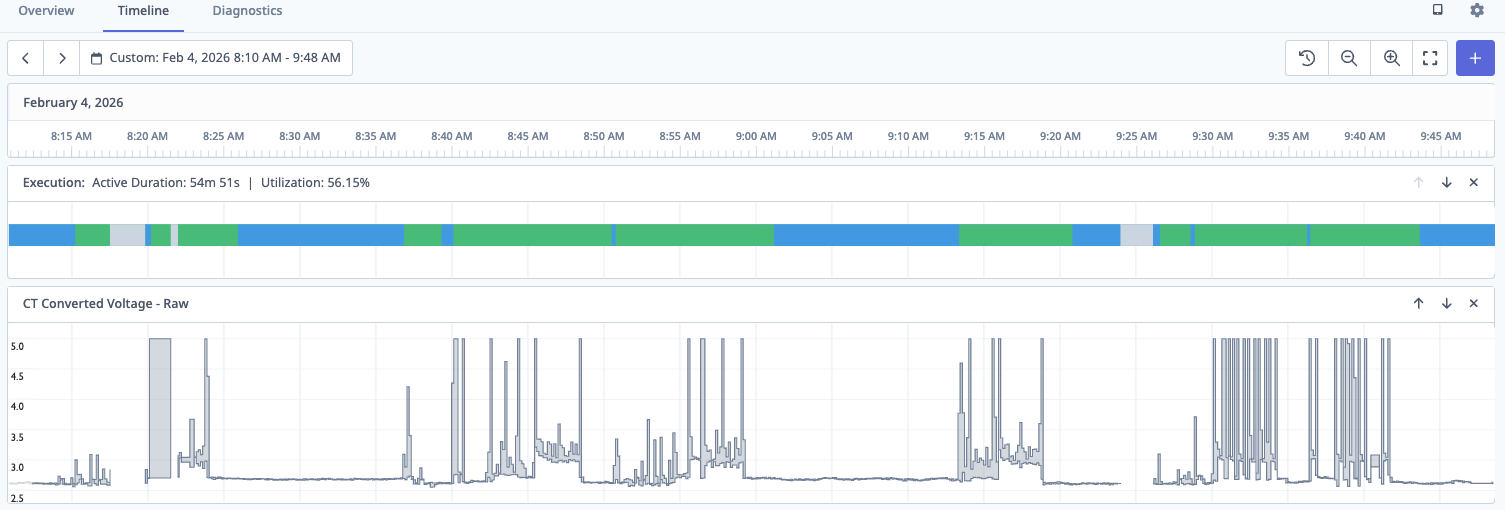

Current transducers measure electrical current to determine machine state (Active/Idle). Use this systematic approach to diagnose and resolve CT-related issues.

Common Symptoms:

- Machine shows Idle while physically running

- Machine shows Active while physically idle

- Erratic switching between Active and Idle states

- Machine state never changes

⚠️ CRITICAL PRINCIPLE: When a machine is completely idle (spindle off, no motors running), the CT voltage should be very low (typically 0.5V - 1.5V). If you see high voltage during idle, the CT is in the wrong location or measuring the wrong circuit.

Understanding CT Switch Positions

Most analog CTs (0-10V output) have three switch positions that determine the current measurement range:

| Switch Position | Current Range | When to Use |

|---|---|---|

| 1 (Low) | 0-50A | Small motors, low-power equipment |

| 2 (Medium) | 0-100A | Most spindle motors, typical CNC equipment |

| 3 (High) | 0-200A | Large motors, high-power machines |

How to Choose: Check the motor nameplate for rated current, then select the switch position that covers that range. Too low = CT maxes out; too high = poor signal separation.

Diagnostic Steps:

-

Review Current Configuration

- Navigate to Machines → [Machine] → Settings → Data Collection

- Document current threshold value and off-delay setting

-

Observe CT Behavior in Timeline

- Go to Machine → Timeline view and enable Live Mode

- Add "CT Converted Voltage - Raw" data item to timeline

- Watch the signal for several minutes while machine cycles

-

Verify Physical Installation

| Checkpoint | ✅ Correct | ❌ Incorrect |

|---|---|---|

| Clamp closure | Fully closed, no gap | Gap visible between halves |

| Cable type | Single conductor only | Multiple wires or cable bundle |

| Location | Spindle motor or main power | General building power |

| Interference | 18"+ from VFDs/transformers | Adjacent to high-voltage equipment |

- Perform Live Testing (Most Critical Step)

Stand at the machine and observe CT voltage during these states:

Test A: Machine Completely Idle

- Spindle OFF, no motors running

- Record idle voltage range (should be < 2.0V)

- If higher: CT is on wrong circuit or switch position too high

Test B: Spindle Running (Not Cutting)

- Start machine, activate spindle at normal speed

- Record active voltage range

Test C: Production (Cutting)

- Load part and begin cutting operation

- Record cutting voltage range

- Calculate Optimal Threshold

Optimal Threshold = (Max Idle Voltage + Min Active Voltage) / 2

Example:

- Idle range: 0.8V to 1.5V (Max = 1.5V)

- Active range: 3.2V to 5.0V (Min = 3.2V)

- Calculation: (1.5 + 3.2) / 2 = 2.35V

- Set threshold to 2.3V or 2.5V

⚠️ Important: You need at least 0.5V separation between max idle and min active.

- Update Adapter Script Configuration

Navigate to Machines → [Machine] → Settings → Data Collection and update your adapter script:

variables:

# Intermediate variable for logic (not output)

ct-voltage-int:

- source: spindle-raw / 409.6 # SeaLevel conversion

# Cleaned variable for data output

ct-voltage:

- source: ct-voltage-int

- resample: 0.5 # Sample every 0.5 seconds

- min-delta: 0.1 # Only send if changed by 0.1V

# Execution state based on threshold

execution:

- source: ct-voltage-int > 2.5 # Your calculated threshold

- off-delay: 90 # Optional delay in seconds

- state:

- ACTIVE: this

- READY: true

data-items:

- execution

- ct-voltage # Output cleaned variable only

⚠️ CRITICAL Variable Naming:

- Always use TWO variables for CT voltage

- Intermediate variable (

ct-voltage-int): Used for threshold logic, never include in data-items - Cleaned variable (

ct-voltage): Usesresampleandmin-deltato reduce noise, safe for data-items - This prevents database overload from noisy analog signals

Common CT Issues & Quick Solutions:

No voltage signal (flat line at 0V)

- Check physical connections at IO module

- Verify Modbus register address in script

- Test with multimeter or swap CT

Constant high voltage (even when machine is off)

- Turn machine off at breaker - CT should drop to ~0V

- If signal persists, CT is on wrong circuit

- Relocate to machine-specific circuit (spindle motor)

- Ensure only single conductor in CT clamp

- Check CT switch position - try higher range setting

Extreme noise / erratic signal

- Move CT 18"+ away from VFDs and transformers

- Reroute CT cable away from high-voltage runs

- Verify cable shielding is intact

Typical Voltage Ranges (Quick Reference):

| Machine State | Typical Voltage | Diagnosis |

|---|---|---|

| Completely Off (breaker off) | 0V - 0.2V | No current flowing |

| Idle / Standby | 0.5V - 1.5V | ✅ Normal baseline |

| ⚠️ High Idle (PROBLEM) | 2.5V - 4.0V | ❌ Wrong circuit or multiple conductors |

| Spindle Running (no load) | 2.5V - 4.0V | Clear increase from idle |

| Cutting / Under Load | 3.5V - 5.0V | Peak activity |

When to Contact Support:

- No voltage signal despite verified connections

- CT signal doesn't correlate with machine behavior

- Overlapping idle/active voltage ranges after relocating CT

- Adapter script changes don't take effect

Include: Machine name, Timeline screenshots showing CT voltage, documented voltage ranges, photos of CT installation, and current adapter script.

False Part Counts

Solutions:

-

Add Auto Mode Logic

part-count:

- source: part-signal and auto-mode

- rising-edge

- count -

Add Pulse Duration Verification (for coolant method)

filtered-signal:

- source: raw-signal

- min-delta: 0.4

- max-delta: 0.7 -

Use Correct Edge Detection

- Try

rising-edgevsfalling-edge - Depends on signal behavior

- Try

Best Practices

Planning:

- Study machine operation before selecting signals

- Review electrical schematics

- Test signals under various conditions

- Document everything

Current Transducers:

- Use analog 0-10V CTs for Sealevel eI/O-170 analog inputs

- Use dry contact CTs for Sealevel eI/O-170 digital inputs (Opto 1/2)

- Clamp around ONE phase only

- Secure CT to prevent vibration

- Set low threshold (1.0-1.5V) for low-speed detection

Wiring:

- Use 18-22 AWG stranded wire

- Label all wires clearly

- Keep wiring neat and organized

- For Sealevel digital inputs: DO NOT apply external voltage (internally powered)

Electrical Safety:

- Never apply >50VDC to any input

- Use relays for AC voltages

- Verify voltage with multimeter

- Follow lockout/tagout procedures

- Work with qualified electricians

Configuration:

- Start with simple adapter scripts

- Test incrementally

- Use descriptive variable names

- CRITICAL: Never output raw analog values in

data-items- Create intermediate variable for logic (e.g.,

ct-voltage-int) - Create cleaned variable with

resampleandmin-deltafor output - Only output cleaned variables to reduce noise and database load

- Create intermediate variable for logic (e.g.,

- Reference: https://developers.machinemetrics.com/docs/adapter-scripts/intro

- Keep backup of working configurations

Part Counting:

- Prefer dedicated part count relay

- Use pallet changer signal when available

- Use barfeeder pulse when applicable

- Coolant pulse method is last resort only

Additional Resources

MachineMetrics Developer Documentation:

- Adapter Scripts Introduction: https://developers.machinemetrics.com/docs/adapter-scripts/intro

- Available Operations: https://developers.machinemetrics.com/docs/adapter-scripts/operations

Sealevel Resources:

- SeaMAX Software Download: https://www.sealevel.com/software-seamax-windows

- eI/O-170 Product Page: https://www.sealevel.com

- Technical Support: (864) 843-4343 or support@sealevel.com

Advantech Resources:

- WISE-4050 Product Page: https://www.advantech.com

- WISE-4050 User Manual (see provided PDF)

- Technical Support: www.advantech.com/support

Purchasing:

- Sealevel eI/O-170: Order from shop.machinemetrics.com

- WISE-4050: Customer-sourced from Advantech or distributors

- Current Transducers: NK Technologies, CR Magnetics, Veris

Getting Help

Before Contacting Support

Gather this information:

- Hardware Details

- Module model (eI/O-170E or WISE-4050)

- Module IP address

- Can you ping the module?

- Machine Details

- Make, model, year

- What signals are you monitoring?

- Signal Information

- What is each input connected to?

- Voltage measurements with multimeter

- Wet or dry contact?

- For CTs: Analog or dry contact output?

- Adapter Script

- Current script (copy/paste)

- What behavior are you seeing vs. expecting?

Contact Options

MachineMetrics Support:

- Email: support@machinemetrics.com

- Include all information above

- Attach photos of wiring

- Include complete adapter script

For Sealevel Hardware:

- Sealevel Support: (864) 843-4343

- Email: support@sealevel.com

- Hardware-specific questions

For WISE Hardware:

- Advantech Support: www.advantech.com/support

- Hardware configuration questions

Ready to connect your machine with I/O?

- Choose hardware: Sealevel eI/O-170 (wired/PoE) or WISE-4050 (wireless)

- Identify signals: CT for execution, appropriate part count method

- Install module and wire signals

- Configure network (static IP)

- Create Modbus TCP adapter script

- Test and refine

Questions? Contact support@machinemetrics.com